The Rising Importance of Carrier Tape Forming Machines in Modern Manufacturing

In the fast-paced world of electronics manufacturing, the demand for efficient and reliable packaging solutions has never been greater. One of the key players in this arena is the Carrier Tape forming machine, a vital piece of equipment that has revolutionized the way electronic components are packaged and transported. As the industry continues to evolve, the significance of these machines is becoming increasingly apparent.

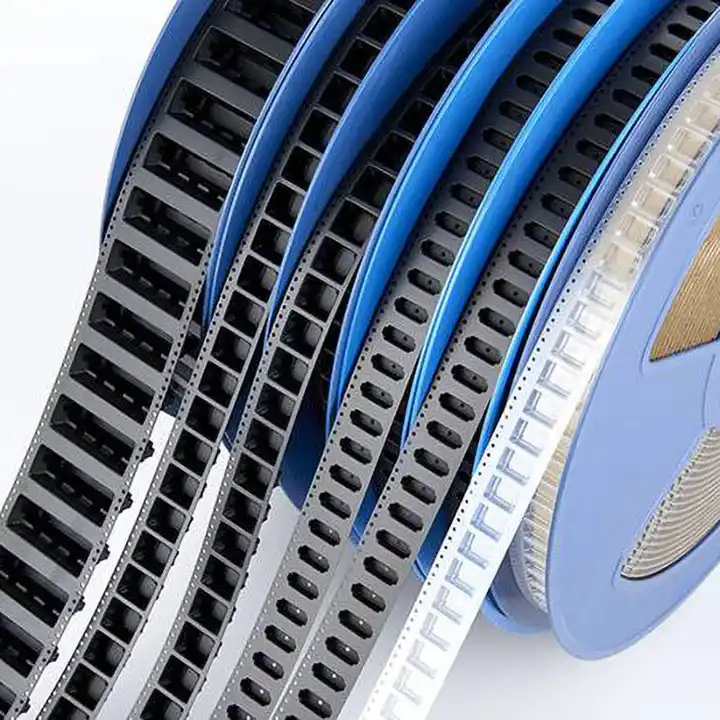

Carrier tape forming machines are designed to create specialized packaging for electronic components, such as semiconductors, resistors, and capacitors. These machines produce carrier Tapes that securely hold components in place, ensuring they are protected during transportation and storage. The importance of this technology cannot be overstated, as it directly impacts the efficiency of the manufacturing process and the quality of the final product.

One of the primary uses of carrier tape forming machines is in the automated assembly of electronic devices. In a world where speed and precision are paramount, these machines enable manufacturers to streamline their operations. By providing a reliable method for packaging components, they reduce the risk of damage during handling and transport, which can lead to costly delays and rework. This efficiency is particularly crucial in high-volume production environments, where even minor disruptions can have significant financial implications.

The advantages of carrier tape forming machines extend beyond mere efficiency. One of the standout benefits is their ability to accommodate a wide range of component sizes and shapes. This versatility allows manufacturers to adapt to changing market demands and technological advancements without the need for extensive retooling. Additionally, modern carrier tape forming machines are equipped with advanced features such as programmable settings and real-time monitoring, which enhance their usability and reliability.

Another significant advantage is the reduction of waste. Traditional packaging methods often result in excess material usage, leading to increased costs and environmental impact. Carrier tape forming machines, on the other hand, are designed to optimize material usage, ensuring that only what is necessary is used for packaging. This not only lowers production costs but also aligns with the growing emphasis on sustainability in manufacturing practices.

Moreover, the integration of carrier tape forming machines into the production line can enhance overall product quality. By providing a consistent and secure packaging solution, these machines help maintain the integrity of electronic components, reducing the likelihood of defects and failures. This is particularly important in industries where reliability is critical, such as automotive and aerospace.

As the electronics industry continues to grow and evolve, the role of carrier tape forming machines will only become more significant. With advancements in technology and increasing demands for efficiency, these machines are poised to play a crucial role in shaping the future of manufacturing. Companies that invest in high-quality carrier tape forming machines will not only improve their operational efficiency but also enhance their competitive edge in the market.

In conclusion, carrier tape forming machines are an indispensable asset in the electronics manufacturing sector. Their ability to provide efficient, versatile, and sustainable packaging solutions makes them essential for modern production lines. As the industry moves forward, the importance of these machines will only continue to rise, solidifying their place as a cornerstone of successful manufacturing operations.