The Introduction of Electronics Component Carrier Tapes

In the rapidly evolving electronics manufacturing industry, the packaging and handling of Components are vital for ensuring efficiency, reliability, and quality. Among the various packaging solutions, carrier tapes have emerged as an essential tool for manufacturers. These specialized tapes not only protect delicate electronic parts but also facilitate automated assembly processes. As the industry continues to advance, understanding the importance, production processes, materials, applications, and features of carrier tapes is essential for manufacturers aiming to enhance their production capabilities.

Importance of Carrier Tapes

Carrier tapes play a critical role in the electronics supply chain. They are designed to securely hold and organize electronic components during storage and transportation, ensuring that parts remain intact and functional. The significance of carrier tapes lies in their ability to minimize the risk of damage during handling and transport, which is crucial in high-volume production environments. By providing a reliable method for packaging components, carrier tapes help manufacturers maintain product quality and reduce costs associated with defects and rework.

Production Process of Carrier Tapes

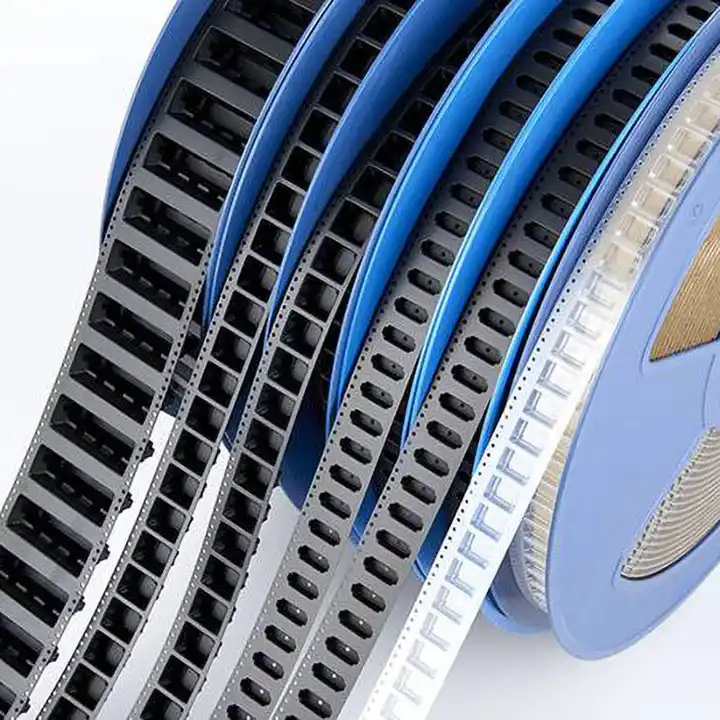

The production of carrier tapes involves several key steps. First, manufacturers select appropriate materials, typically high-quality plastics such as polycarbonate or polyethylene, which provide durability and protection. The carrier tape is then formed into a continuous strip with evenly spaced pockets or cavities designed to fit specific components. This process may involve techniques such as injection molding or thermoforming. After the tape is produced, it undergoes rigorous quality control checks to ensure that the dimensions and strength meet industry standards. Finally, the carrier tapes are wound onto reels for easy handling and integration into automated assembly lines.

Materials Used in Carrier Tapes

Carrier tapes are primarily made from durable plastic materials that offer excellent protection against physical damage and environmental factors. Common materials include:

-

Polycarbonate: Known for its high impact resistance and clarity, polycarbonate is often used for applications requiring visibility of the components inside the tape.

-

Polyethylene: This lightweight and flexible material is commonly used for standard carrier tapes, providing a good balance of durability and cost-effectiveness.

-

Conductive Materials: For sensitive electronic components, carrier tapes may be made from conductive plastics that help dissipate static electricity, protecting components from electrostatic discharge (ESD).

Applications of Carrier Tapes

Carrier tapes are widely used across various sectors of the electronics industry. They are essential for packaging components such as semiconductors, resistors, capacitors, and integrated circuits. The design of these tapes allows for the safe placement of components, making them ideal for automated assembly lines in consumer electronics, automotive, telecommunications, and medical devices. Their ability to facilitate quick and accurate retrieval of components enhances overall productivity and efficiency in manufacturing processes.

Features of Carrier Tapes

Carrier tapes are designed with several key features that enhance their functionality and usability:

-

Durability: Constructed from robust materials, carrier tapes are built to withstand the rigors of transportation and handling, ensuring that components remain protected throughout the supply chain.

-

Compatibility with Automated Systems: Carrier tapes are designed to work seamlessly with automated pick-and-place machines, allowing for quick and accurate component retrieval. This integration significantly enhances production efficiency.

-

Versatility: The ability to accommodate various component sizes and shapes makes carrier tapes suitable for a wide range of applications across different sectors.

-

Sustainability: Many carrier tapes are designed to minimize material waste, aligning with the growing emphasis on eco-friendly practices in manufacturing.

In conclusion, carrier tapes are an essential component in the electronics manufacturing sector. Their importance, diverse applications, various materials, and essential features make them indispensable for modern production lines. As the industry continues to advance, the role of carrier tapes will only grow, solidifying their position as a cornerstone of efficient and reliable manufacturing operations.