The Importance of Carrier Tapes in Electronics Component Packaging

In the rapidly advancing field of electronics manufacturing, the packaging and handling of Components are critical to ensuring efficiency, reliability, and quality. Among the various packaging solutions, carrier tapes have emerged as a fundamental tool for manufacturers. These specialized tapes not only protect delicate electronic parts but also facilitate automated assembly processes. As the industry continues to evolve, understanding the importance, uses, types, and features of carrier tapes is essential for manufacturers aiming to enhance their production capabilities.

Importance of Carrier Tapes

Carrier tapes play a vital role in the electronics supply chain. They are designed to securely hold and organize electronic components during storage and transportation, ensuring that parts remain intact and functional. The significance of carrier tapes lies in their ability to minimize the risk of damage during handling and transport, which is crucial in high-volume production environments. By providing a reliable method for packaging components, carrier tapes help manufacturers maintain product quality and reduce costs associated with defects and rework.

Uses of Carrier Tapes

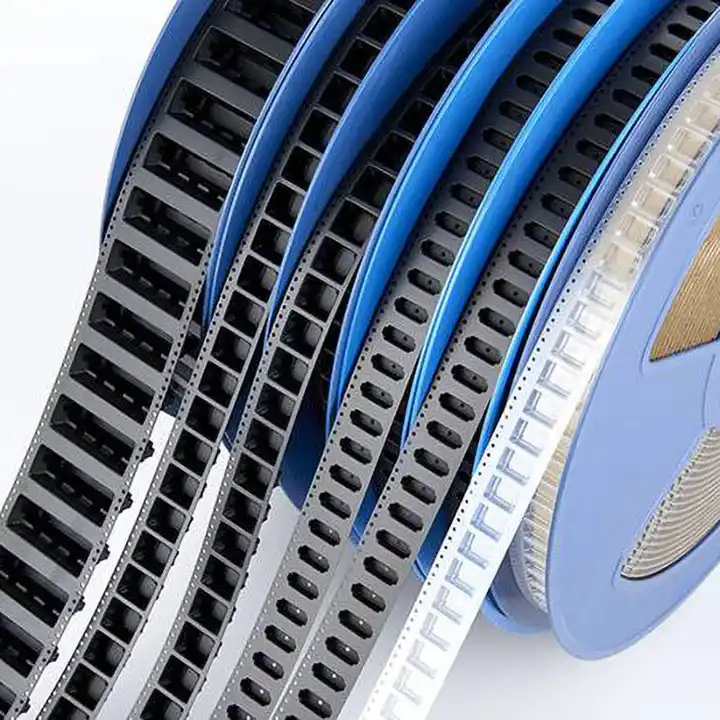

Carrier tapes are primarily used to package a wide range of electronic components, including semiconductors, resistors, capacitors, and integrated circuits. The design of these tapes allows for the safe placement of components in individual pockets along a continuous strip, making them ideal for automated assembly lines. This organization is essential for ensuring that components can be quickly and accurately retrieved by automated pick-and-place machines, streamlining the assembly process and enhancing overall productivity.

Types of Carrier Tapes

Carrier tapes come in various types, each tailored to accommodate different component sizes and shapes:

-

Standard Carrier Tape: This type is widely used for standard electronic components and features uniform pocket sizes and spacing. It is suitable for a variety of applications in consumer electronics.

-

Embossed Carrier Tape: Designed for components with irregular shapes or larger sizes, embossed carrier tape features molded pockets that securely fit specific components. This type is often used for larger semiconductors and specialized electronic parts.

-

Conductive Carrier Tape: Made from materials that prevent static electricity buildup, conductive carrier tape is ideal for sensitive electronic components that can be damaged by electrostatic discharge (ESD). This type is essential in industries where component reliability is critical.

-

Custom Carrier Tape: For manufacturers with unique requirements, custom carrier tape can be designed to meet specific needs. This flexibility allows companies to optimize their packaging solutions for specialized components.

Features of Carrier Tapes

Carrier tapes are designed with several key features that enhance their functionality and usability:

-

Durability: Constructed from robust materials, carrier tapes are built to withstand the rigors of transportation and handling, ensuring that components remain protected throughout the supply chain.

-

Compatibility with Automated Systems: Carrier tapes are designed to work seamlessly with automated pick-and-place machines, allowing for quick and accurate component retrieval. This integration significantly enhances production efficiency.

-

Versatility: The ability to accommodate various component sizes and shapes makes carrier tapes suitable for a wide range of applications across different sectors, including consumer electronics, automotive, and telecommunications.

-

Sustainability: Many carrier tapes are designed to minimize material waste, aligning with the growing emphasis on eco-friendly practices in manufacturing. This not only reduces costs but also supports manufacturers’ sustainability goals.

In conclusion, carrier tapes are an essential component in the electronics manufacturing sector. Their importance, diverse uses, various types, and essential features make them indispensable for modern production lines. As the industry continues to advance, the role of carrier tapes will only grow, solidifying their position as a cornerstone of efficient and reliable manufacturing operations.