The Essential Role of Carrier Tape Reels in Electronics Packaging

In the rapidly evolving landscape of electronics manufacturing, the importance of effective packaging solutions cannot be overstated. Among these solutions, carrier tape reels have emerged as a critical component in the efficient handling and transportation of Electronic Parts. As the demand for smaller, more complex electronic devices continues to rise, understanding the significance, applications, and features of carrier tape reels becomes increasingly vital for manufacturers.

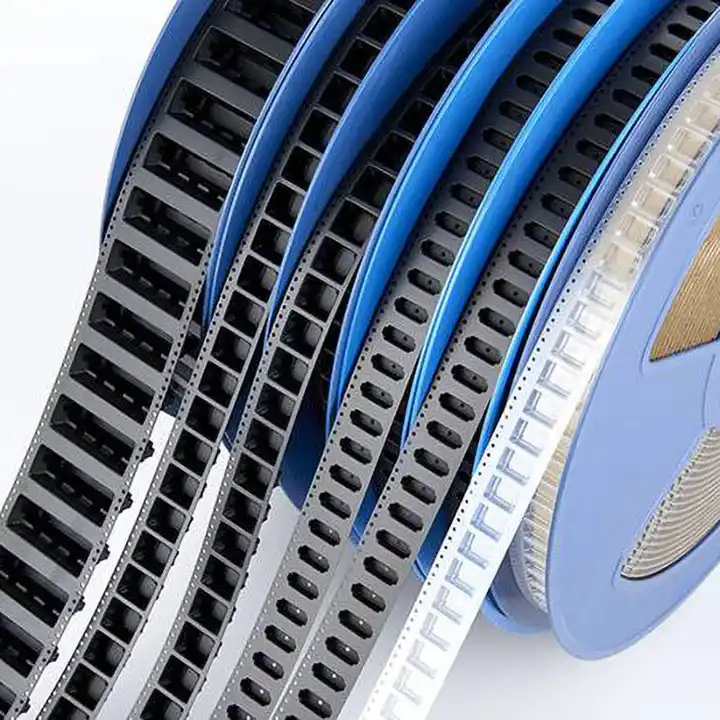

Carrier tape reels are designed to hold and protect electronic Components during storage and transportation. They consist of a continuous strip of plastic tape with pockets or cavities that securely house individual components. This innovative packaging method not only safeguards delicate parts from damage but also facilitates automated assembly processes, making it an indispensable tool in modern manufacturing.

One of the primary uses of carrier tape reels is in the automated assembly of electronic devices. In an industry where speed and precision are paramount, these reels enable manufacturers to streamline their operations. By providing a reliable and organized method for packaging components, carrier tape reels minimize the risk of damage during handling and transport. This efficiency is particularly crucial in high-volume production environments, where even minor disruptions can lead to significant financial losses.

The advantages of carrier tape reels extend beyond their protective capabilities. One of the standout features is their compatibility with automated pick-and-place machines, which are widely used in the assembly of electronic devices. These machines can quickly and accurately pick components from the carrier tape, significantly speeding up the assembly process. This integration not only enhances productivity but also reduces labor costs, allowing manufacturers to allocate resources more effectively.

Another important characteristic of carrier tape reels is their versatility. They can accommodate a wide range of component sizes and shapes, making them suitable for various applications across different sectors, including consumer electronics, automotive, and telecommunications. This adaptability allows manufacturers to respond swiftly to changing market demands and technological advancements without the need for extensive retooling.

Moreover, carrier tape reels contribute to sustainability efforts in the manufacturing process. Traditional packaging methods often result in excess material usage, leading to increased costs and environmental impact. Carrier tape reels, designed for optimal material usage, help minimize waste, aligning with the growing emphasis on eco-friendly practices in the industry. This not only lowers production costs but also enhances a company’s reputation as a responsible manufacturer.

In addition to their practical benefits, carrier tape reels also play a crucial role in maintaining product quality. By providing a consistent and secure packaging solution, they help ensure that electronic components remain intact and functional throughout the supply chain. This is particularly important in industries where reliability is critical, such as aerospace and medical devices.

As the electronics industry continues to grow, the role of carrier tape reels will only become more significant. Companies that invest in high-quality carrier tape solutions will not only improve their operational efficiency but also enhance their competitive edge in the market.

In conclusion, carrier tape reels are an essential component in the electronics manufacturing sector. Their ability to provide efficient, versatile, and sustainable packaging solutions makes them indispensable for modern production lines. As the industry evolves, the importance of these reels will continue to rise, solidifying their place as a cornerstone of successful manufacturing operations.