The Essential Role of Carrier Tape Cover Tape in Electronics Packaging

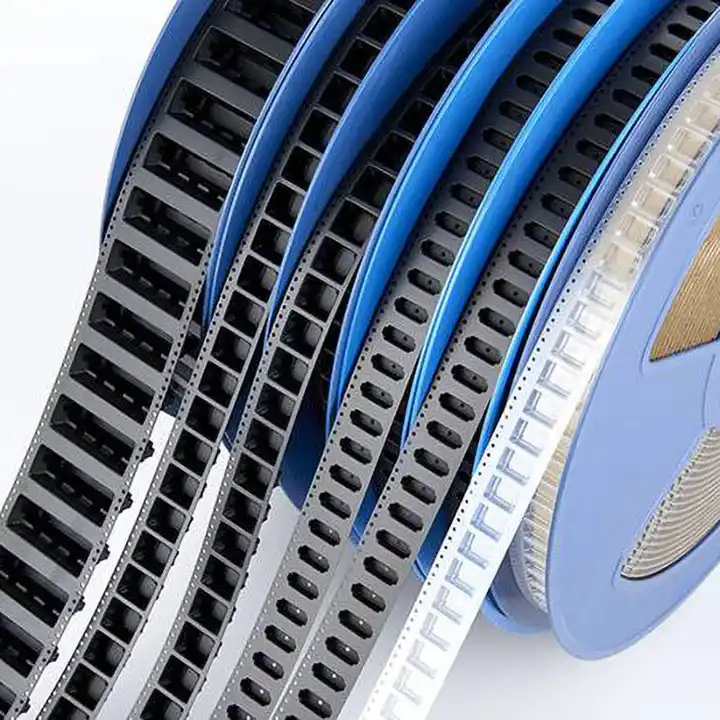

In the ever-evolving landscape of electronics manufacturing, effective packaging solutions are crucial for ensuring the safe transport and handling of components. Among these solutions, Carrier Tape covers have emerged as an essential component in the packaging process. These covers not only protect delicate electronic parts but also enhance the efficiency of automated assembly lines. As the industry continues to advance, it is important to explore the uses, types, and features of carrier tape covers.

Uses of Carrier Tape Cover Tape

Carrier tape covers serve a vital purpose in the packaging of electronic components. They are designed to securely seal the components housed within the carrier tape, preventing them from dislodging or becoming damaged during transportation and handling. This protective layer is particularly important in high-speed manufacturing environments, where components are subjected to vibrations and movements that could lead to misalignment or damage. By providing a secure closure, carrier tape covers ensure that components remain intact and ready for assembly, thereby reducing the risk of defects and enhancing overall product quality.

Types of Carrier Tape Cover Tape

Carrier tape covers come in various types, each tailored to meet specific packaging needs:

-

Standard Carrier Tape Covers: These are commonly used for a wide range of electronic components. They are typically made from durable plastic materials that provide a reliable seal while allowing for easy access to the components during assembly.

-

Conductive Carrier Tape Covers: Designed for sensitive electronic components that are susceptible to electrostatic discharge (ESD), these covers are made from conductive materials that help dissipate static electricity. This is crucial in protecting components such as semiconductors and integrated circuits from potential damage.

-

Custom Carrier Tape Covers: For manufacturers with unique requirements, custom carrier tape covers can be designed to fit specific component shapes and sizes. This flexibility allows companies to optimize their packaging solutions for specialized applications.

-

Transparent Carrier Tape Covers: These covers are made from clear materials, allowing for easy visibility of the components inside. This feature is particularly useful for quality control and inventory management, as it enables manufacturers to quickly assess the contents without opening the packaging.

Features of Carrier Tape Cover Tape

Carrier tape covers are designed with several key features that enhance their functionality and usability:

-

Durability: Made from robust materials, carrier tape covers are built to withstand the rigors of transportation and handling, ensuring that components remain protected throughout the supply chain.

-

Compatibility with Automated Systems: Carrier tape covers are designed to work seamlessly with automated pick-and-place machines, allowing for quick and accurate component retrieval. This integration significantly enhances production efficiency.

-

Ease of Use: Many carrier tape covers are designed for easy application and removal, allowing manufacturers to quickly access components during the assembly process without compromising the integrity of the packaging.

-

Cost-Effectiveness: By reducing the risk of damage and defects, carrier tape covers help manufacturers save on costs associated with rework and replacement, making them a cost-effective solution in the long run.

In conclusion, carrier tape covers play a crucial role in the electronics manufacturing sector. Their diverse uses, various types, and essential features make them indispensable for modern production lines. As the industry continues to advance, the importance of carrier tape covers will only grow, solidifying their position as a cornerstone of efficient and reliable manufacturing operations.