Leave Your Message

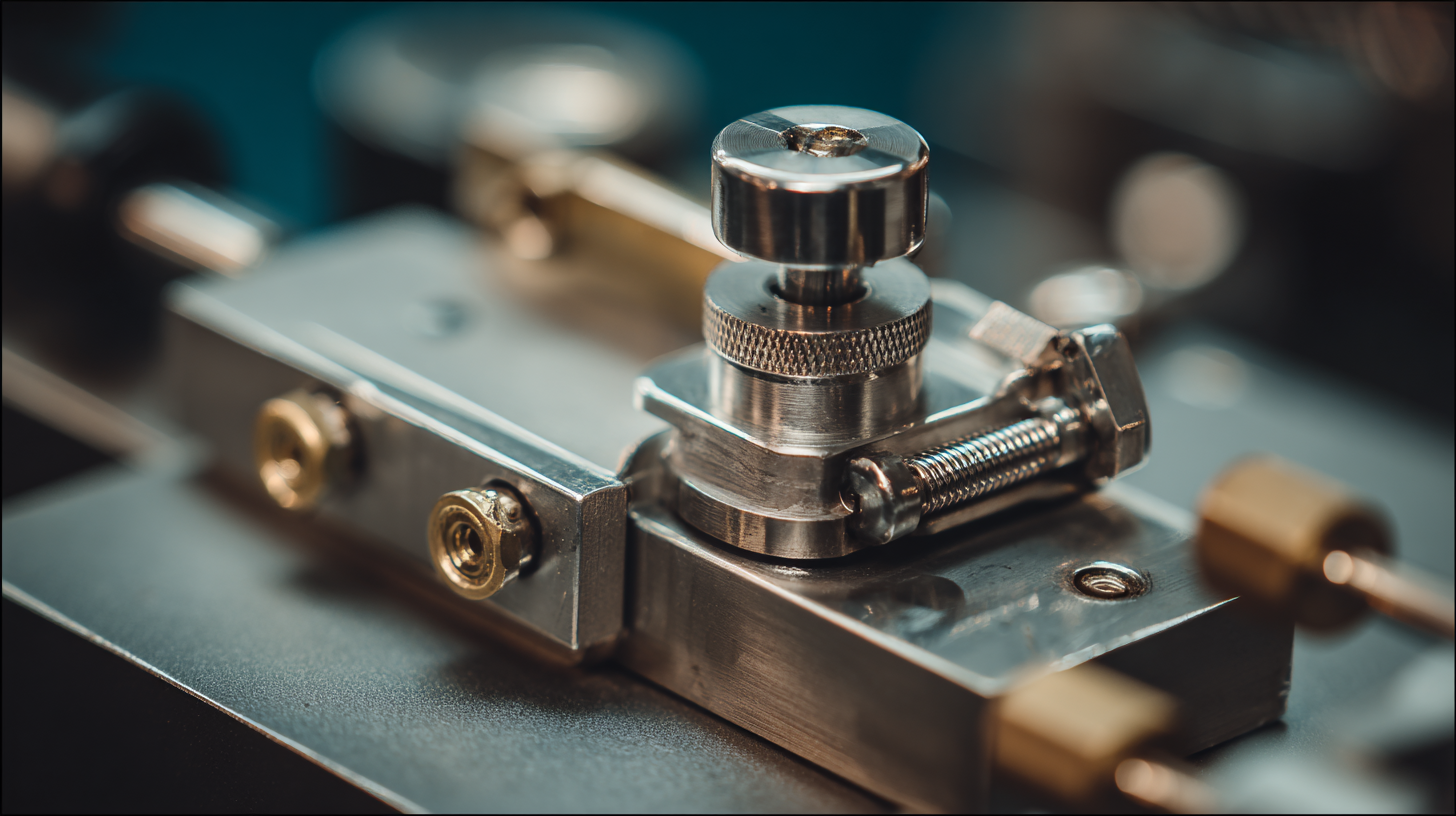

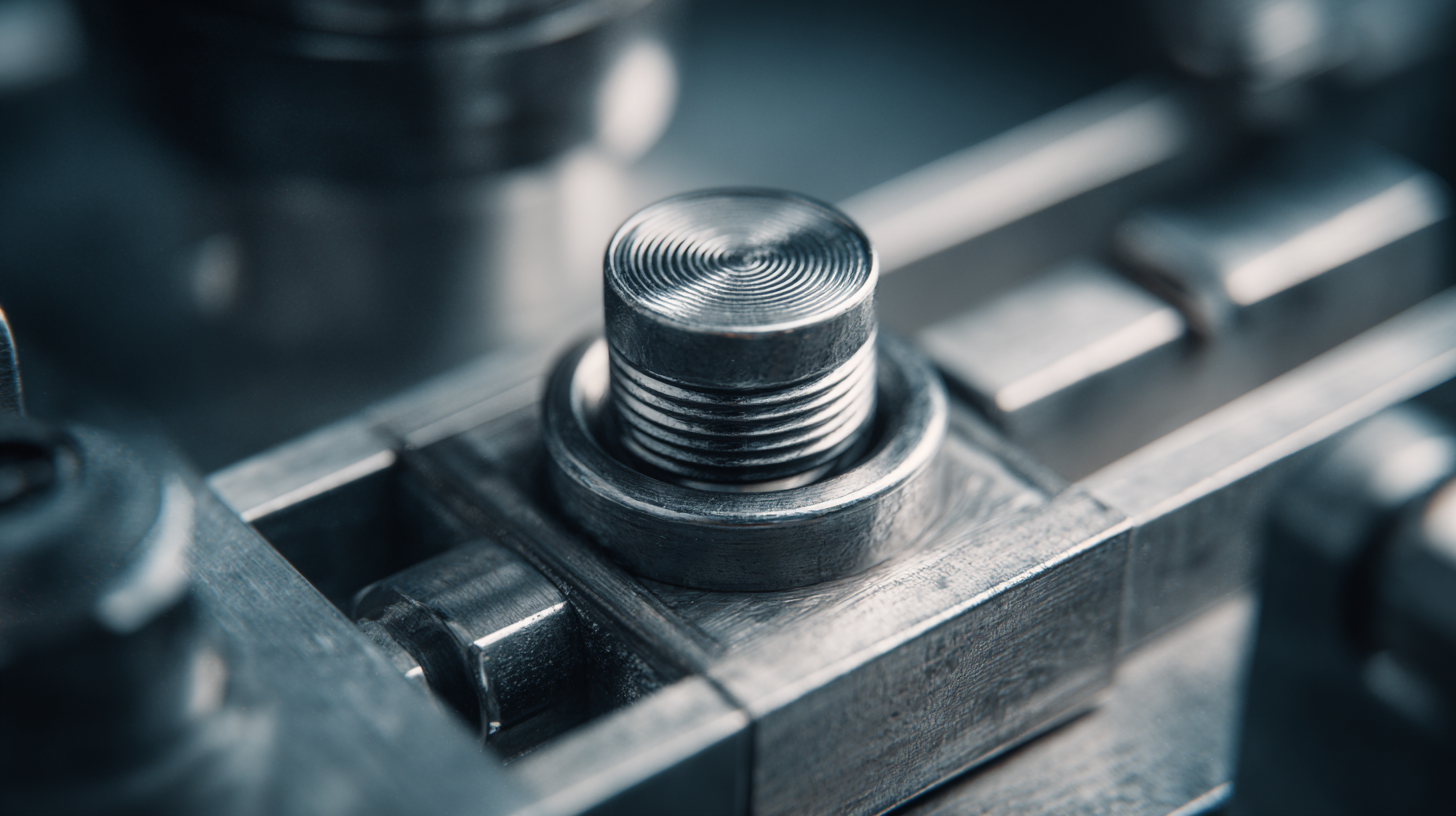

In the realm of modern machinery, the integration of innovative components has become critical for enhancing efficiency and user experience. One such component, the Special Spring-Loaded Button, has garnered significant attention for its capacity to optimize operational performance. According to a report by the Industrial Automation Association, the adoption of advanced control mechanisms like spring-loaded buttons can improve machinery responsiveness by up to 30%, thereby reducing operational downtime.

Furthermore, a study published in the Journal of Manufacturing Science revealed that machines equipped with these buttons experience a 25% increase in user satisfaction, thanks to their intuitive design and ease of use. As industries strive for automation and precision, the Special Spring-Loaded Button stands out as a pivotal solution, enabling operators to interact seamlessly with complex systems while enhancing overall productivity.

Furthermore, a study published in the Journal of Manufacturing Science revealed that machines equipped with these buttons experience a 25% increase in user satisfaction, thanks to their intuitive design and ease of use. As industries strive for automation and precision, the Special Spring-Loaded Button stands out as a pivotal solution, enabling operators to interact seamlessly with complex systems while enhancing overall productivity.

Incorporating spring-loaded buttons in industrial equipment design offers numerous advantages that enhance both functionality and user experience. According to industry reports, spring-loaded mechanisms can significantly reduce operational fatigue, allowing operators to engage machinery with minimal effort. This is particularly beneficial in high-frequency applications where ease of use can lead to increased productivity and decreased downtime.

One of the standout benefits of spring-loaded buttons is their ability to provide tactile feedback, which is crucial in a noisy industrial environment. This feedback enhances user confidence, ensuring that actions are being registered correctly, thus minimizing errors. Furthermore, spring-loaded buttons can be designed to withstand harsh conditions, including dust and moisture, ensuring longevity and reliability.

Tips: When selecting a spring-loaded button for industrial applications, consider the environmental conditions it will face. Look for buttons with an IP67 rating for dust and water resistance. Additionally, ensure the button’s actuation force aligns with the operational needs of your machinery to optimize usability and reduce user strain. Lastly, explore customization options that allow integration with existing systems for better compatibility and efficiency.

When selecting a spring-loaded button for your machinery, several critical factors must be considered to ensure optimal performance and functionality. First, assess the operational environment of the machinery. According to a recent report by Machinery Insights, approximately 30% of machinery failures are attributed to component incompatibility with environmental conditions such as humidity, temperature, and dust. Choose a button designed to withstand your specific conditions—look for features like weatherproofing and corrosion resistance.

Another key consideration is the button's actuation force and travel distance. The right specifications will depend on the application and user requirements. A survey by Automation Trends indicated that 45% of operators expressed difficulty with buttons that have overly stiff or loose actuation. Thus, testing multiple options to find a balance between tactile feedback and pressure sensitivity is essential.

**Tip:** When in doubt, consult with manufacturers to get samples for testing in real-world scenarios. This practical approach helps in assessing how well different buttons meet the demands of your machinery.

**Tip:** Keep in mind the ease of installation and maintenance. Opt for buttons that offer straightforward installation processes, as downtime can significantly impact productivity.

Installing spring-loaded buttons in modern machinery is a straightforward yet essential process that can dramatically enhance operational efficiency. According to a report by the International Journal of Industrial Automation and Control, machines equipped with specially designed controls, such as spring-loaded buttons, can experience a reduction in operator errors by up to 30%. This significant improvement stems from the intuitive nature of the buttons, allowing operators to engage mechanisms quickly and reliably.

To achieve optimal performance, the first step involves selecting the right spring-loaded button based on the machinery's design and operational requirements. For example, the force exerted by the spring should match the application—too soft may lead to unintentional activation, while too hard could impair usability. Comprehensive guidelines from the Machinery Component Design Institute recommend that machinery setups should allow at least 20% of button travel to accommodate variations caused by wear over time.

Once the appropriate button is selected, installation requires precise alignment to ensure effective function. It's advisable to use CAD modeling software to visualize the integration of buttons within the machinery framework, which can help identify potential issues before actual installation. Regular maintenance checks should be scheduled, as noted in the Machinery Maintenance Report, which highlights that proactive upkeep increases the longevity of components by an average of 25%. Implementing these practices will harness the full potential of spring-loaded buttons, leading to enhanced productivity and safety in modern machinery operations.

To ensure the longevity of spring-loaded button mechanisms, regular maintenance is essential. First, keep the buttons clean and free from debris that could hinder their movement. Dirt or dust accumulation can cause friction, leading to premature wear and tear. A soft cloth or compressed air can effectively remove particles without damaging the mechanism.

To ensure the longevity of spring-loaded button mechanisms, regular maintenance is essential. First, keep the buttons clean and free from debris that could hinder their movement. Dirt or dust accumulation can cause friction, leading to premature wear and tear. A soft cloth or compressed air can effectively remove particles without damaging the mechanism.

Additionally, lubrication is crucial in maintaining smooth operation. Use a lightweight oil specifically designed for mechanical components to prevent rust and reduce friction. Applying lubrication to the moving parts of the button mechanism every few months can significantly extend its life.

Lastly, inspect the springs regularly for signs of fatigue or deformation. A worn spring may not provide the necessary force for reliable operation, which can affect the overall functionality of the machinery it serves. Replacing any damaged components immediately can prevent further issues and ensure that the machinery operates efficiently and safely.

The integration of spring loaded buttons in modern manufacturing processes has revolutionized various industries by enhancing operational efficiency and safety. According to a report by the International Society for Automation, nearly 75% of manufacturing facilities now employ advanced button technologies to streamline production lines. These specialized buttons, designed to provide an immediate mechanical response, reduce cycle times and improve the ergonomics of machinery, ultimately leading to increased productivity.

Innovatively, spring loaded buttons have found applications across diverse sectors, from automotive assembly lines to electronics manufacturing. A study by the Manufacturing Institute revealed that companies utilizing spring loaded solutions reported a 30% decrease in assembly errors and a 20% enhancement in workflow efficiency. These buttons not only facilitate quick operations but also serve as safety mechanisms, preventing accidental machine starts.

As industries continue to seek smarter, safer, and more efficient manufacturing methods, the adoption of spring loaded buttons stands out as a pivotal choice for achieving operational excellence.