Leave Your Message

In the realm of manufacturing and custom design, choosing the right "Spring Makers" is crucial for ensuring the success of your projects. Spring makers are not just providers of essential components; they are partners in innovation that can influence everything from product longevity to performance optimization. According to a recent industry report from TechSci Research, the global market for spring manufacturing is projected to exceed $10 billion by 2026, highlighting the growing demand for high-quality springs across various sectors, including automotive, electronics, and aerospace. With an array of materials, designs, and manufacturing techniques available, understanding how to select the best spring makers is paramount for engineers and project managers alike. This guide will navigate you through the essential criteria and considerations for choosing spring makers that align with your project requirements, ensuring you make informed decisions that enhance the overall effectiveness of your product designs.

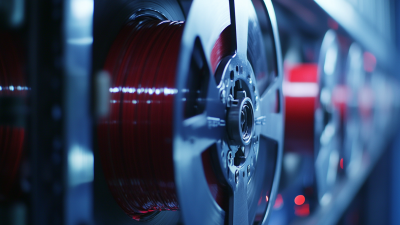

When selecting the right spring maker for your projects, it is essential to understand the different types available and their specific applications. There are various kinds of spring makers, including mechanical, electronic, and hand-operated models. Mechanical spring makers typically offer greater durability and are suited for high-volume production. These machines excel in creating a wide range of spring sizes and shapes with consistent results, making them ideal for industrial applications where precision and efficiency are paramount.

On the other hand, electronic spring makers incorporate advanced technology, allowing for customization and intricate design capabilities. They are particularly beneficial in fields like automotive and aerospace, where specifications can be quite demanding. Hand-operated spring makers, although less common in industrial settings, provide a more hands-on approach and can be advantageous for small projects and artistic endeavors. Understanding the strengths and limitations of each type enables you to choose the best spring maker tailored to your specific needs, ensuring that your projects achieve the desired outcomes.

When choosing the best spring maker for your projects, it's essential to focus on key features that enhance functionality and ease of use. One vital factor is the machine's versatility—look for models that can handle various spring types and sizes to ensure you can tackle diverse projects. Additionally, consider the material quality; a durable spring maker made from high-grade components will not only improve performance but also extend the life of the machine.

Another critical aspect to evaluate is the ease of operation. A user-friendly design can significantly reduce the learning curve, allowing you to jump right into your projects. Look for features like adjustable settings, clear displays, and comprehensive guides to streamline your experience.

Tips: Always check customer reviews to gauge the reliability of the spring maker you’re considering. It's also helpful to visit forums or online communities where users share their experiences and troubleshooting advice. These insights can help you make an informed decision and enhance your overall crafting experience.

When embarking on DIY projects that require spring-making, one of the most significant decisions you'll face is choosing between manual and electric spring makers. According to a report by the International Journal of Engineering and Technology, the efficiency of electric spring makers has improved by 35% over the past five years, allowing for quicker production times and increased precision. This advancement is particularly beneficial for projects requiring consistent spring sizes and tensions, as electric models often reduce human error in the crafting process.

Conversely, manual spring makers remain popular for their simplicity and affordability. The same report indicates that approximately 48% of DIY enthusiasts still prefer manual tools, appreciating the tactile control and craftsmanship involved. Manual spring makers allow users to engage more deeply with their projects, often leading to unique, one-of-a-kind spring designs.

Ultimately, the choice between manual and electric spring makers will depend on the complexity of the project, the user’s budget, and their personal preference for the crafting process. Understanding these aspects will help you make an informed decision that best suits your DIY needs.

When it comes to selecting the right spring maker for your projects, understanding the top brands and models available today can significantly enhance your crafting experience. Leading manufacturers like **Simpson Strong-Tie**, **Anvil**, and **Apex** offer a diverse range of spring makers designed for various applications. For instance, Simpson Strong-Tie is renowned for its user-friendly design and durability, making it a great choice for hobbyists and professionals alike. Meanwhile, Anvil's focus on precision engineering ensures that their products can handle heavy-duty requirements, ideal for industrial use.

When evaluating spring makers, consider the project scope and the specific type of springs you intend to create. Pay attention to features like adjustable tension settings and interchangeable dies, which can expand the versatility of your spring maker. Moreover, investing in models with robust customer support and warranty coverage will provide added peace of mind. Lastly, user reviews can offer valuable insights into the performance and reliability of different models, helping you make an informed decision.

For those new to spring making, start with a basic model to master the technique before moving on to advanced options. Additionally, always prioritize safety by using protective gear and ensuring proper workspace organization to prevent accidents. This approach will help you get the most out of your spring maker and foster a rewarding crafting journey.

| Model | Type | Wire Diameter Range | Max Spring Length | Features | Price Range |

|---|---|---|---|---|---|

| Model A | Coiling Machine | 0.2 - 4 mm | 500 mm | Digital Control, High Speed | $1,000 - $1,500 |

| Model B | Compression Spring Maker | 1 - 8 mm | 300 mm | Automatic Feed, Multiple Sizes | $800 - $1,200 |

| Model C | Torsion Spring Maker | 0.5 - 5 mm | 150 mm | Programmable Settings, Compact | $950 - $1,400 |

| Model D | Flat Spring Maker | 0.3 - 7 mm | 600 mm | High Precision, User-Friendly | $1,200 - $1,800 |

When it comes to maximizing the performance of your spring maker, proper maintenance and optimization are key. Regularly checking and lubricating moving parts can significantly extend the lifespan of your machine. A well-maintained spring maker will operate smoothly, reducing friction and wear, therefore producing consistent and quality springs. Be sure to consult your machine’s manual for specific maintenance schedules and recommended lubricants, as neglecting these can lead to costly repairs and downtime.

Additionally, fine-tuning your spring maker settings for different materials and spring types can enhance efficiency. Experimenting with variables such as tension and coil diameter allows you to achieve the desired specifications for your projects. Keeping a log of successful settings can serve as a reference for future jobs, streamlining the production process. Furthermore, regularly updating your knowledge of industry advancements and technological improvements in spring-making can provide a competitive edge and inspire innovative designs. Embrace these practices to ensure your spring maker operates at peak performance while delivering the best results for your projects.

This chart illustrates the performance ratings of various spring makers based on user evaluations. The ratings are based on a scale of 1 to 10, reflecting the quality and consistency of each product.