Leave Your Message

The evolution of user interfaces in modern devices has significantly transformed the way we interact with technology, with touch button springs emerging as a pivotal component in this landscape. According to a report by the Consumer Technology Association, around 70% of consumers prioritize tactile feedback in their device interfaces, highlighting the crucial role that touch button springs play in enhancing user experience. These springs not only provide the necessary mechanical response but also contribute to ergonomic design, ensuring that users receive intuitive and satisfying feedback during their interactions.

With the global market for user interface technologies projected to reach $100 billion by 2026, it is imperative to explore the intricate mechanisms of touch button springs, as their design and functionality directly influence user satisfaction and product usability. By focusing on these essential components, manufacturers can create devices that not only meet but exceed user expectations in terms of responsiveness and comfort.

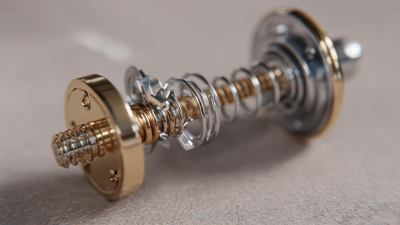

Touch button springs play a crucial role in modern devices, enhancing user experience by providing tactile feedback and precision during operation. These springs, often made from a variety of metals such as brass, stainless steel, and carbon steel, are integral to the functionality of touch switches. They are designed to respond to user interaction, allowing for seamless operation in devices that require quick and reliable inputs. Understanding their basic functionality reveals how they enable a more intuitive and responsive user interface.

The construction of touch button springs is engineered to ensure durability and a consistent performance under repeated use. Their design often incorporates materials that support various environmental conditions while maintaining the integrity of the user experience. As seen in advanced technologies, like steering wheels in motorsports, where precision and control are paramount, the role of these springs extends beyond simple functionality. They contribute significantly to the overall performance, making interactions not only easier but also more efficient in complex systems.

The mechanism of touch button springs plays a pivotal role in enhancing user experience across modern devices. Advanced designs leverage unique materials that not only improve performance but also provide tactile feedback essential for user interaction. Key materials include stainless steel, which offers durability and resistance to wear, making it a popular choice in high-usage environments. Its elasticity ensures that the spring can return to its original shape without deformation, thereby maintaining consistent functionality over time.

Another critical material is plastic composites, which are increasingly used in advanced designs due to their lightweight characteristics and flexibility. These composites can be engineered to achieve various hardness levels, allowing designers to tailor the button's responsiveness to specific applications. Additionally, the integration of silicone rubber has emerged as a game-changer for touch button springs, providing a soft touch and greater comfort for users. This material's unique properties also contribute to water and dust resistance, extending the lifespan of devices while ensuring reliability in diverse conditions. Through the thoughtful selection of these materials, modern touch button spring designs continue to evolve, significantly impacting user interaction and satisfaction.

The interaction between users and modern devices hinges significantly on the design and mechanics of touch button springs. These springs not only provide tactile feedback but also dictate the responsiveness of the button, which can heavily influence a user’s overall experience. A well-engineered spring mechanism can enhance a user's confidence in the device, allowing for a more intuitive interaction. By optimizing the compression and rebound characteristics of these springs, manufacturers can create a seamless and enjoyable user experience that resonates with consumers' expectations of modern technology.

Drawing parallels from the world of design, much like how nature-inspired collections evoke a deep emotional response, the mechanics behind touch buttons can also elicit feelings of comfort and satisfaction. The precision and reliability of spring mechanics lead to a harmonious interaction that mirrors the organic inspiration seen in creative fields. Devices that prioritize thoughtful spring design not only elevate functionality but also pave the way for aesthetic excellence, fostering a connection between users and the technology they engage with daily.

Touch buttons have become an integral part of modern devices, offering both enhanced aesthetics and functionality. However, the performance of these touch button springs is critical to achieving the desired user experience. According to a report by the International Society for Precision Engineering, optimizing the spring's elasticity and response time can improve user satisfaction by up to 25%. Proper testing techniques, such as applying force measurements and analyzing feedback loops, allow engineers to fine-tune the spring properties, thereby minimizing lag and ensuring a seamless interaction.

In addition to elasticity and response time, durability is another key factor. A study published in the Journal of Mechanical Engineering noted that springs designed with advanced materials can withstand over 10 million actuations without significant wear. Testing methods, including fatigue testing and environmental simulations, help manufacturers assess the long-term viability of their touch button springs. By employing these optimization techniques, companies not only enhance the performance of their devices but also gain a competitive edge in the rapidly evolving tech market.

The future of touch button spring technology is poised for significant evolution, driven by advancements in materials science and user-centric design. One key trend is the integration of smart materials, such as shape memory alloys and electroactive polymers, which can adapt their properties in response to environmental stimuli. These materials not only enhance tactile feedback but also allow for thinner and more compact device designs, ultimately improving user interaction. As devices become increasingly sleek and minimalistic, the demand for innovative spring systems that provide satisfying tactile responses without adding bulk will likely grow.

Moreover, the design of touch button springs is moving towards customization and personalization. With the rise of user interface (UI) design trends that prioritize emotional engagement, manufacturers are exploring ways to allow users to adjust the sensitivity and feedback of touch buttons according to their preferences. This could include features like adjustable resistance or modular designs that facilitate quick changes to spring characteristics. As technology becomes more focused on the individual user experience, we can expect touch button spring technology to evolve into a more adaptive and personalized component of modern devices, further enhancing their functionality and usability.

| Dimension | Current Trends | User Experience Impact | Future Innovations |

|---|---|---|---|

| Material Type | Use of advanced alloys and composites | Improved tactile feedback | Biodegradable materials |

| Manufacturing Process | Precision engineering and automation | Higher durability and reliability | 3D printing techniques |

| Design Trends | Minimalistic and ergonomic designs | Increased comfort in prolonged use | Smart touch responsiveness |

| User Customization | Options for personal touch resistance | Enhanced user satisfaction | Adaptive feedback systems |

| Integration with Technology | Compatibility with IoT devices | Seamless connectivity and operation | AI-based personalization |