Leave Your Message

In today's fast-paced design landscape, innovative components play a critical role in product development. The adoption of Special Spring-Loaded Buttons has surged. Recent industry analyses predict an annual growth rate of over 5% in demand for such components by 2025. These buttons enhance functionality, offering tactile feedback and increased reliability in various applications.

Special Spring-Loaded Buttons can be found in diverse sectors, from consumer electronics to automotive design. Their reliability and user-friendly nature contribute to their popularity. However, not all designs meet the high standards expected. Some may face issues with responsiveness and durability. Addressing these challenges is vital for manufacturers to succeed in the competitive market.

The variety in Special Spring-Loaded Button types offers endless possibilities for customization. Designers need to carefully select the appropriate type for their projects. This is where detailed specifications and performance metrics matter. A failure to understand these can lead to unsatisfactory outcomes. Engaging with professionals and reviewing data can pave the way for better design choices.

Spring loaded buttons are a vital component in various applications. They provide a simple yet effective way to enhance user interaction. These buttons work automatically, returning to their original position after being pressed. This feature can improve functionality in many devices, from gaming controllers to industrial tools.

When selecting a spring loaded button, consider the force required for activation. You might prefer a lighter touch for delicate tasks, while heavy-duty applications may need more resistance. Choosing the right force determines user experience. Poor selection can lead to frustration and reduce efficiency.

Tips: Always test button responsiveness. Make adjustments based on user feedback. Also, think about the button's placement in your project. Visibility and accessibility can significantly affect its usability.

Incorporating these buttons into your designs can create more interactive products. They are versatile and can be used in various fields. Their simple mechanics belies their impact. Reflect on how users interact with them. Small changes in design can lead to dramatic improvements in user satisfaction.

| Button Type | Activation Force (Newtons) | Travel Distance (mm) | Application Area | Notes |

|---|---|---|---|---|

| Tactile Button | 1.5 | 2.0 | Consumer Electronics | Provides tactile feedback for user assurance. |

| Sticky Button | 2.0 | 3.5 | Industrial Equipment | Holds its position under pressure until released. |

| Momentary Button | 1.0 | 4.0 | Control Panels | Ideal for applications requiring quick on-off actions. |

| Push-Pull Button | 2.5 | 5.0 | Automotive Controls | Often used for engine start/stop functions. |

| Locking Button | 3.0 | 2.5 | Security Systems | Prevents accidental activation, securing the function. |

Spring loaded buttons come in various types, each designed for specific applications. The push button is one of the most common types. It offers simplicity and reliability. These buttons work well in consumer electronics and automotive applications. They often contain a spring mechanism that returns the button to its original position after being pressed.

Another notable type is the momentary switch. This switch only stays active while being pressed. It's ideal for scenarios where temporary actions are needed, like in toys or gaming devices. The tactile feedback is satisfying for users, enhancing the overall experience.

Tips: Choose buttons with the right tactile feedback. Consider user comfort and the desired response time.

Rotary spring loaded buttons add versatility to designs. They can offer different functions based on rotation. This type can be tricky to integrate due to space considerations.

Tips: Test the user interface. Functionality can sometimes be mismatched with design preferences.

Always assess the environment where the buttons will be used. Factors like temperature and moisture can affect performance. Moreover, the choice of materials matters. A mismatch can lead to premature failure or user dissatisfaction. Selecting the right spring loaded button improves both usability and the lifespan of your project.

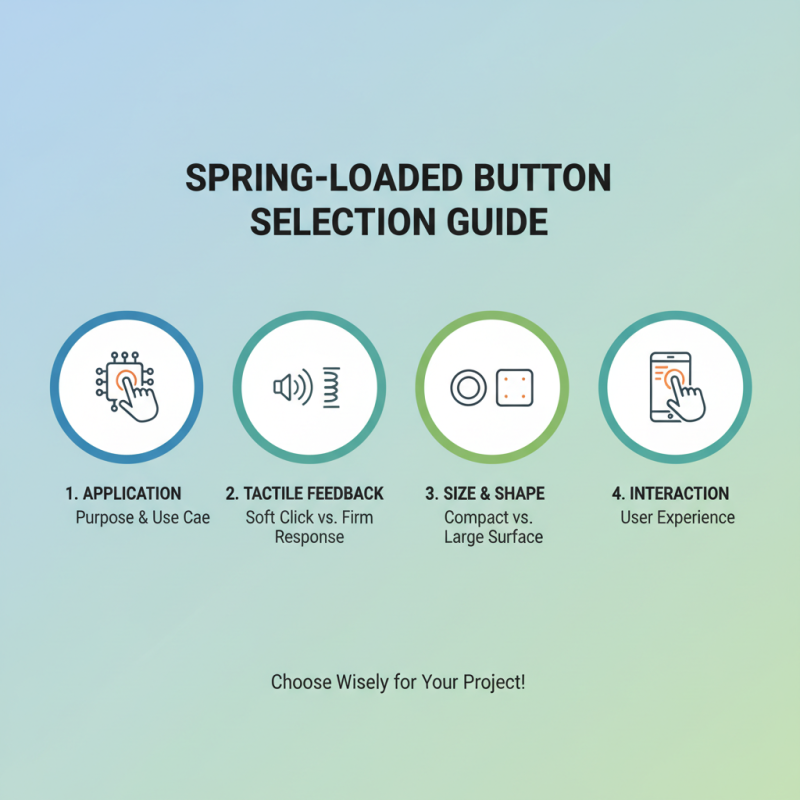

When selecting the right spring-loaded button for your project, consider its application. Different designs serve various purposes. Think about the tactile feedback you want. A softer click may fit some needs, while a firmer response might be better for others. Pay attention to the size and shape as well. Compact buttons work well in smaller devices, while larger ones offer more surface area for interaction.

Also, assess the button's durability. Some environments are harsher than others. If your project faces frequent use or exposure to the elements, choose materials that withstand wear and tear. Remember some buttons might wear out quickly under heavy use. Testing prototypes can help address these concerns.

Lastly, ensure compatibility with your circuit. Some buttons require specific voltage ranges or current ratings. Double-check specifications before committing to a design. It’s easy to overlook these details amidst the excitement of creating. Always reassess your choices for alignment with the project's goals and user experience.

When working with spring loaded buttons, installation is crucial. Proper alignment can prevent common issues, such as misfiring or sticking. Some reports indicate that about 25% of operational failures stem from improper installation. Make sure to follow detailed guidelines. This includes checking the button's mechanism before mounting.

Maintenance is just as important. Regularly inspect the buttons for wear and tear. Dust and debris can build up, leading to performance degradation. Industry statistics show that routine cleaning can extend the lifespan of these components by up to 30%. However, many users neglect this step, which can lead to frustrating malfunctions.

Using lubricants can help, but the right type is essential. Not all lubricants are suitable for every button type. Lightweight oils may work better than heavy greases in some cases. Users often overlook this, which can result in poor function over time. Be proactive in your approach to maintenance, and consider keeping a maintenance log. This can help identify recurring issues and trends in button performance.

This chart illustrates the popularity of various types of spring loaded buttons based on recent survey data among engineering professionals.

Spring loaded buttons have become essential in various industries. Their innovative designs improve functionality and user experience. In the automotive sector, for example, reports indicate that over 20% of car designers have integrated these buttons for features like engine start-stop. They are also popular in household appliances, making devices easier and safer to operate. The convenience of a quick-release feature enhances daily interactions with technologies.

These buttons support industries ranging from medical devices to consumer electronics. In medical applications, spring loaded buttons can be found in surgical tools, allowing for precise operations. A recent study showed that implementing these buttons improved safety measures by reducing user error rates by about 15%. Yet, it's crucial to note that not all designs will work for every application. Designers must test prototypes thoroughly.

Tip: When choosing a spring loaded button, consider the force required for actuation. Balancing sensitivity and reliability is key.

In consumer products, they enhance usability in gadgets. However, inconsistencies in quality can lead to frustration. Industry insights reveal that a lack of proper feedback from such buttons can result in dissatisfaction. Users may think the function did not engage. Understanding user needs is vital.

Tip: Focus on feedback during testing. A button that feels right in simulation may not succeed in the real world.