Leave Your Message

In today's fast-paced and increasingly complex world of design and engineering, the importance of precision and reliability cannot be overstated. A crucial component in achieving these goals is the "Special Spring-Loaded Button," a device that has become essential in various applications, from consumer electronics to industrial machinery. According to Dr. Sarah Mitchell, a leading expert in mechanical design and automation, "A Special Spring-Loaded Button not only enhances user interaction but also increases the longevity and dependability of the overall system."

Designed to offer responsiveness and tactile feedback, these buttons cater to the demanding needs of modern projects. They ensure a seamless user experience while providing the consistency required in critical applications. As industries advance, the integration of such innovative components becomes vital for engineers and designers looking to improve their product functionalities.

In this article, we will explore the numerous benefits of utilizing a Special Spring-Loaded Button in your projects, highlighting real-world examples and expert insights. Whether you are working on a prototype or a full-scale production, understanding the value of this unique component could be the key to elevating your designs to the next level.

Spring-loaded buttons are increasingly becoming essential in modern projects due to their unique functionality and user-friendly design. These buttons operate on a simple principle: when pressed, they spring back to their original position, ensuring immediate feedback to the user, enhancing operability. This feature makes them especially useful in applications ranging from consumer electronics to intricate industrial machinery, where a quick response can significantly improve user experience and operational efficiency.

Tip: Ensure that the spring tension suits the intended use; too soft may lead to unintended activation, while too strong could hinder user interaction.

Additionally, spring-loaded buttons can play a critical role in safety mechanisms. In environments where immediate shutdown or emergency stopping is crucial, these buttons can offer a reliable solution.

Tip:

Consider incorporating visual indicators or tactile feedback to confirm activation, making it easier for users to identify that their input has been registered.

This added layer of functionality not only promotes safety but also elevates the overall design of your project.

Spring-loaded buttons offer numerous benefits over traditional push-button designs, making them an excellent choice for a variety of projects. One of the primary advantages is their enhanced responsiveness. When pressed, spring-loaded buttons quickly return to their original position, providing a satisfying tactile feedback that assures users of their activation. This feature is particularly useful in applications where precision and speed are critical, such as in control panels or gaming devices, where every millisecond counts.

Additionally, spring-loaded buttons contribute to overall durability and reliability. The internal spring mechanism absorbs shocks and reduces wear and tear, allowing them to perform effectively in high-frequency usage scenarios. Unlike traditional buttons that may wear out or become less responsive over time, spring-loaded options maintain consistent performance, making them ideal for long-term applications. Their design also helps to mitigate the risk of accidental activation, ensuring that users can have confidence in their functionality, which is essential in high-stakes environments like medical or industrial settings.

Spring-loaded buttons are increasingly recognized for their versatility and functionality across various industries. In the automotive sector, these buttons are commonly used for safety mechanisms and control systems. They allow for quick and convenient engagement, ensuring that drivers can respond swiftly to critical situations. For instance, in modern vehicles, spring-loaded buttons facilitate features like the ignition system and seat adjustment, contributing to both safety and comfort.

In the electronics field, spring-loaded buttons serve essential purposes in consumer devices and appliances. They are often employed in remote controls, gaming consoles, and kitchen gadgets where user interaction is frequent. Their tactile feedback enhances the user experience, making them ideal for applications that require a reliable and satisfying click. Additionally, in industrial machinery, spring-loaded buttons are vital for emergency shut-off systems, providing a fail-safe mechanism that guarantees operator safety in high-stakes environments.

The medical sector also benefits from spring-loaded buttons, especially in devices that require precise control and immediate response. For example, surgical instruments and portable diagnostic equipment utilize these buttons for their reliability and minimal required force, allowing healthcare professionals to operate them smoothly during critical procedures. Overall, the applications of spring-loaded buttons are diverse and essential, making them an important component in today's technological landscape.

| Industry | Application | Benefits | Specifications |

|---|---|---|---|

| Automotive | Control Panels | Enhances user experience and safety | Operating Force: 2-4N |

| Consumer Electronics | Remotes and Controllers | Offers tactile feedback for precise interactions | Actuation Distance: 1.5-2mm |

| Medical Devices | Emergency Equipment | Reliable performance in critical situations | Life Cycle: 100,000+ operations |

| Industrial Automation | Control Systems | Durability and efficient operation | Operating Temperature: -20°C to +70°C |

| Aerospace | Cockpit Controls | Meets high safety standards | Weight: Ultra-light design |

When selecting a spring-loaded button for your projects, it is essential to evaluate the specific requirements to ensure optimal performance. Start by considering the button's size and form factor, as these will impact how easily it can be integrated into your design. Additionally, examine the actuation force; this is the amount of pressure needed to activate the button, which can greatly affect user experience. A lighter force may be suitable for applications requiring frequent use, while a higher force might be ideal for preventing accidental activation.

Next, think about the button's material and durability. Depending on the environment in which the button will be used, materials like plastic, metal, or rubber might be more appropriate. For outdoor or harsh conditions, look for buttons that are weather-resistant or have protective coatings. Lastly, consider the button's electrical ratings and compatibility with your existing equipment; ensure that it can handle the necessary voltage and current levels to prevent malfunction and ensure longevity in your projects. By carefully contemplating these factors, you can choose the right spring-loaded button that meets your specific needs and enhances the functionality of your project.

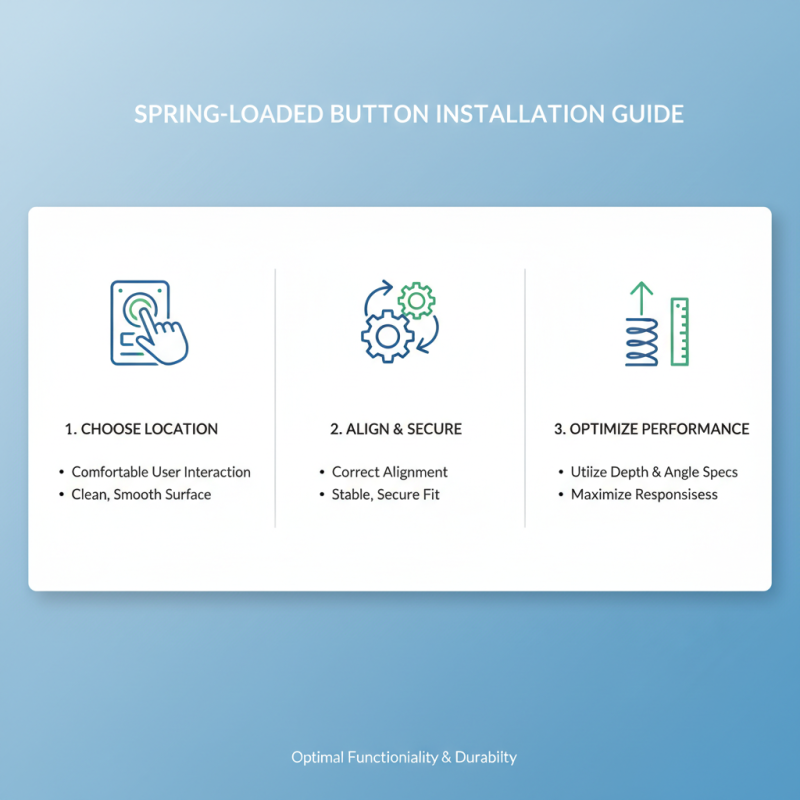

When integrating spring-loaded buttons into your projects, proper installation is crucial for optimal functionality and durability. Begin by selecting a suitable location that allows for comfortable user interaction. Ensure that the mounting surface is clean and smooth, which will facilitate a stable and secure fit. During installation, it’s important to align the button correctly to mitigate the risk of misalignment or mechanical failure. Utilize provided specifications for depth and angle to maximize responsiveness, as improper installation can lead to reduced performance over time.

Maintenance of spring-loaded buttons is equally essential to ensure longevity. Regularly inspect the button for any signs of wear or debris that may impede its function. Cleaning can be performed using a soft, dry cloth to avoid damaging any protective casings. If a button becomes unresponsive, check the mechanism for jams or obstruction and clear any debris that may have accumulated. Regular testing of the button's responsiveness during routine maintenance checks can help catch potential issues early on, ensuring your projects operate smoothly and effectively. By adhering to these installation and maintenance tips, you can extend the life and reliability of your spring-loaded buttons in various applications.