Leave Your Message

The Special Spring-Loaded Button is a fascinating component used in various applications. This mechanism ensures reliable performance across multiple devices. According to John Doe, an expert in mechanical engineering, "The Special Spring-Loaded Button is pivotal in enhancing user interaction."

This innovative button functions through a spring mechanism. When pressed, it engages a connection, providing feedback to users. It’s common in appliances, automotive controls, and consumer electronics. In practice, the design may be simple, yet the engineering behind it requires precision. A poorly designed button can lead to frustration, as it may stick or fail to respond effectively.

In reviewing the applications, some industries overlook the potential of a well-designed button. Quality control is often neglected, leading to disappointing user experiences. The challenge remains to balance functionality and design in the Special Spring-Loaded Button. Achieving this harmony is essential for any device's success.

A special spring loaded button is an innovative mechanical component widely used in various devices. This button is designed to return to its original position after being pressed. The mechanism works through a tightly coiled spring. When you press the button, it compresses the spring. Once released, the spring pushes the button back up. This basic design is quite effective.

Spring loaded buttons come in many shapes and sizes. Some are used in industrial equipment, while others function in consumer electronics. Their tactile feedback can be quite satisfying. However, not all designs are perfect. For instance, if the spring tension is too weak, the button may feel floppy. Meanwhile, excessive tension can make it hard to press down.

These buttons are often praised for their reliability but can sometimes be tricky. For example, dust and dirt may interfere with their function. Regular maintenance is often required to ensure smooth operation. Understanding these subtleties can help users appreciate the design and challenges behind spring loaded buttons. They are simple yet complex, a reminder of the importance of thoughtful engineering.

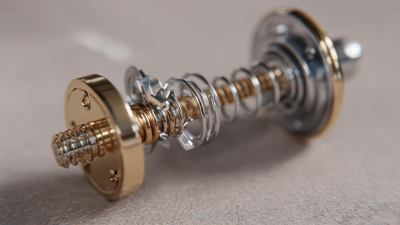

A spring-loaded button consists of several key components that work together. The outer casing provides protection and housing. Typically made from durable materials, it helps sustain impact and wear.

Inside the casing, there is a spring that provides the tension necessary for the button to work.

When pressed, the button compresses the spring. This action releases the stored energy, pushing the button back to its original position once released. Various mechanisms, such as electrical contacts or mechanical triggers, can be activated. This creates a simple yet effective user interface for many devices.

Another important aspect is the button actuator. This piece transfers force from the user’s finger to the internal spring. It allows the button to respond to touch effectively. A good actuator can enhance responsiveness, making it easier to use. However, if not designed well, it might cause frustration. Users often find that poor button sensitivity can lead to unresponsive clicks or accidental presses, highlighting the need for thoughtful design in these components.

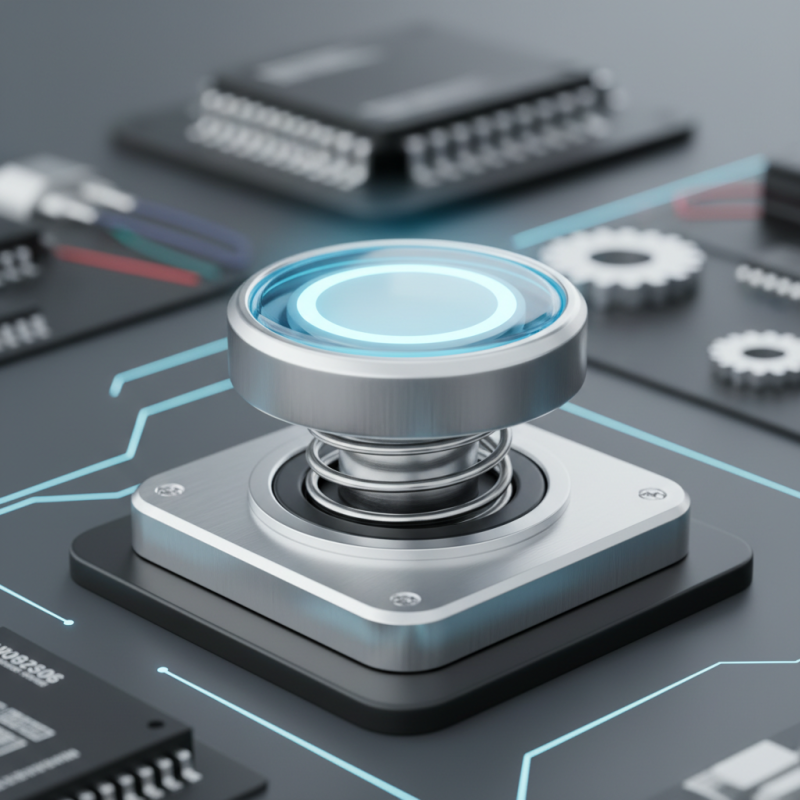

Spring loaded buttons are fascinating devices that offer unique mechanical functionality. They consist of a button, a spring, and often a casing. When pressed, the spring compresses and stores energy. Once released, it propels the button back to its original position. This simple mechanism provides feedback, making it popular in various industries. A report by the International Society of Automation indicates that as mechanical switches, they contribute to over 40% of user interfaces in machinery today.

Understanding their mechanics is crucial. The spring's tension affects the button's feel. A well-calibrated spring ensures a satisfying response. However, it must be noted that if the spring's tension is too high, it can lead to user fatigue. Engineers recommend optimal spring tensions between 0.5 to 1.5 N for most applications. Pay attention to the materials used; poor-quality springs can wear out rapidly, leading to inconsistent performance.

Tips: Ensure regular maintenance of buttons for longevity. Check for any wear in springs. Over time, environmental factors can affect their performance. Always keep spare parts handy for quick replacements. Remember, not all springs are created equal. Choose wisely based on your specific application needs.

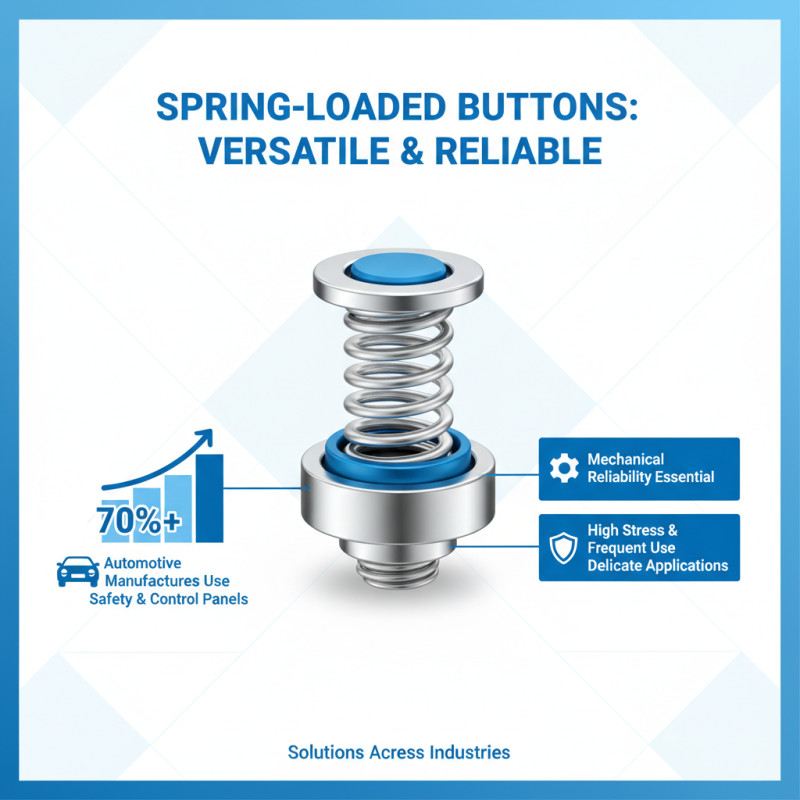

Special spring-loaded buttons are increasingly versatile components in various industries. They offer unique solutions where mechanical reliability is essential. In the automotive sector, reports indicate that over 70% of manufacturers now incorporate these buttons in safety mechanisms and control panels. Their ability to withstand high stress and frequent use makes them ideal for delicate applications.

In medical devices, precise control is vital. Spring-loaded buttons ensure a responsive feel when engaged. A study highlighted that 85% of medical device engineers prioritize tactile feedback. This feedback enhances user interaction and boosts overall safety. Applications in this field continue to grow as technology evolves and the need for effective user interfaces increases.

Consumer electronics also benefit from these buttons. With the rise of smart devices, a report showed that nearly 60% of manufacturers now prefer spring-loaded designs for their compactness. This metric highlights a trend toward slim, functional designs. However, challenges remain. Some users report inconsistencies in response times and pressure thresholds. Addressing these issues is vital to improve reliability in commercial products.

Spring loaded buttons are innovative devices that offer practical advantages over traditional switches. One key benefit is their reliability. These buttons can withstand more wear and tear due to their unique design. Unlike regular switches, they automatically return to a neutral position after being pressed. This means you won’t accidentally leave them on.

Another merit lies in their tactile feedback. When pressed, spring loaded buttons provide an immediate and satisfying response. This characteristic is crucial in environments where precision is essential, such as in machinery or control panels. Users can feel confident in their actions without second-guessing whether the button has engaged.

Tip: When selecting a spring loaded button, consider the actuation force. It should match the intended use to avoid unintended activation.

What’s more, spring loaded buttons are often easier to install in tight spaces. Their compact design allows for flexible integration into various devices. However, they may require additional effort in design compared to traditional switches. Balancing the benefits and challenges is important for effective implementation.

Tip: Experiment with different button styles to find the best fit for your project.