Leave Your Message

In today's rapidly evolving manufacturing landscape, the demand for compact and efficient components is higher than ever, with the global market for small touch springs projected to reach $1.5 billion by 2027, according to recent industry reports. Small touch springs are essential in a variety of applications, including consumer electronics, automotive controls, and medical devices, providing the necessary tactile feedback for user interfaces. However, selecting the right small touch springs for your project needs can be a complex process, influenced by factors such as material properties, spring constants, and packaging constraints. This blog will delve into the top factors to consider when choosing small touch springs, helping you optimize performance and reliability in your designs. By understanding these key elements, you can ensure that your projects not only meet but exceed market expectations.

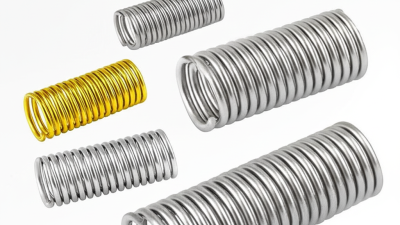

When selecting the right small touch springs for your project needs, understanding their fundamental characteristics is crucial. Small touch springs, commonly used in a variety of applications from electronics to automotive components, play an essential role in ensuring the functionality and reliability of devices. These springs are typically manufactured from materials like stainless steel or phosphor bronze, which offer excellent elasticity and durability. According to industry reports, the global spring market is expected to grow at a CAGR of 4.7% from 2021 to 2028, underscoring the increasing importance of high-quality spring components in modern designs.

**Tips for Selecting Small Touch Springs:**

1. **Material Matters:** Choose a spring material that can withstand the specific environmental conditions it will be exposed to, such as humidity or temperature variations.

2. **Load Requirements:** Assess the load requirements of your application. Springs need to be able to handle the required compression or tension without failing.

3. **Dimensional Accuracy:** Pay close attention to the dimensions of the spring. Accurate sizing is vital to ensure that the spring fits perfectly within its designated space.

By focusing on these fundamental aspects, you can make informed decisions that will enhance the performance and longevity of your projects. Understanding these elements ensures that the selected springs will meet both functional and design criteria efficiently.

| Dimension | Description | Material | Load Capacity (N) | Length (mm) | Outer Diameter (mm) | Spring Rate (N/mm) |

|---|---|---|---|---|---|---|

| M2 | Light touch response | Stainless Steel | 1.5 | 10 | 4 | 0.15 |

| M3 | Medium touch response | Alloy Steel | 3.0 | 12 | 5 | 0.25 |

| M4 | Heavy touch response | Copper-Nickel | 5.0 | 15 | 6 | 0.35 |

When selecting the right small touch springs for your project, it is crucial to begin by identifying your specific project requirements. Consider factors such as load specifications, environmental conditions, and the intended application of the spring. A recent industry report highlights that springs used in precision instruments must often adhere to tight tolerances, with over 60% of failures attributed to incorrect spring specifications. Understanding the operational parameters and desired performance characteristics will guide you towards a spring that can deliver optimal results.

In addition to mechanical properties such as wire diameter and material type, project needs may involve compliance with industry standards. For instance, many electronic applications now require springs that meet RoHS (Restriction of Hazardous Substances) guidelines, reflecting a growing trend towards more sustainable practices. Moreover, the sensitivity of touch mechanisms can be influenced significantly by spring design, emphasizing the need to select springs that not only achieve functional goals but also enhance user experience.

Leveraging tools and resources available from manufacturers can streamline the selection process, helping you pinpoint the ideal springs for your specific demands.

When selecting small touch springs for your projects, the choice of materials is crucial for ensuring optimal performance. Various materials offer different properties that affect the durability, responsiveness, and functionality of the springs. For instance, stainless steel is known for its excellent corrosion resistance and strength, making it ideal for applications exposed to moisture. On the other hand, brass springs provide good conductivity and are often favored in electronic devices where a reliable connection is critical.

Another material option to consider is plastic, particularly for lightweight and non-corrosive needs. Plastic touch springs can be ideal for applications where reducing weight is essential, but they may not offer the same level of longevity as metal counterparts. Additionally, composite materials are gaining popularity, as they blend the benefits of both metal and plastic, offering enhanced durability while remaining lightweight. Ultimately, the best choice depends on the specific requirements of your project, such as load capacity, environmental conditions, and required lifespan. Proper comparisons and evaluations of these materials will lead to better performance of touch systems in various applications.

When selecting small touch springs for your project, understanding force and travel specifications is crucial. The force specification refers to the amount of resistance the spring provides when it is compressed or extended. This is typically measured in grams or ounces and should align with the operational requirements of your application. For instance, if you're designing a delicate mechanism, a lower force spring may be ideal to prevent excessive wear. Conversely, for a more robust application where durability is essential, a higher force spring would be necessary to ensure longevity and performance.

Travel specifications indicate the distance the spring can compress or extend during operation. This measurement is significant in applications where space is constrained or precision is needed. Choosing a spring with the right travel length ensures that it can adequately perform its function without limiting the movement of other components. Therefore, it's imperative to evaluate the geometry and design of your assembly when determining the travel specification. By accurately assessing both force and travel specifications, you can select the right small touch springs that will meet your project requirements and enhance overall product performance.

When it comes to sourcing and testing touch springs for your project needs, understanding the procurement process is crucial. Recent advancements have shown that streamlined procurement methods, such as those implemented by contracting professionals, can significantly reduce lead times and labor costs. For instance, adopting efficient systems can accelerate acquisitions, making it easier to acquire the necessary components for your projects without overspending.

Before implementation, thorough testing is imperative. Industry reports suggest that about 30% of projects face delays due to inadequate component quality control. To avoid this, it’s important to conduct rigorous testing on touch springs to ensure they meet specific performance criteria. This includes checking for durability, flexibility, and responsiveness, ensuring they align with user expectations and project requirements.

Additionally, using data from sourcing platforms can enhance your decision-making process. A study found that leveraging comprehensive supplier databases can lead to a 20% improvement in sourcing efficiency. By prioritizing suppliers who demonstrate a commitment to quality and robust testing protocols, you’ll secure components that not only meet your needs but also enhance the overall performance of your project.