Leave Your Message

In the world of electronics, "Plastic Carrier Tape" plays a crucial role. Dr. Sarah Kim, an expert in packaging solutions, once noted, "Plastic Carrier Tape ensures that components are delivered safely and efficiently." This statement highlights the significance of plastic tapes in the electronics supply chain.

Plastic Carrier Tape is designed to transport various electronic components securely. Its structure allows for precise placement and protection during the manufacturing process. In addition, the materials used offer durability and flexibility, ensuring components remain intact throughout shipping.

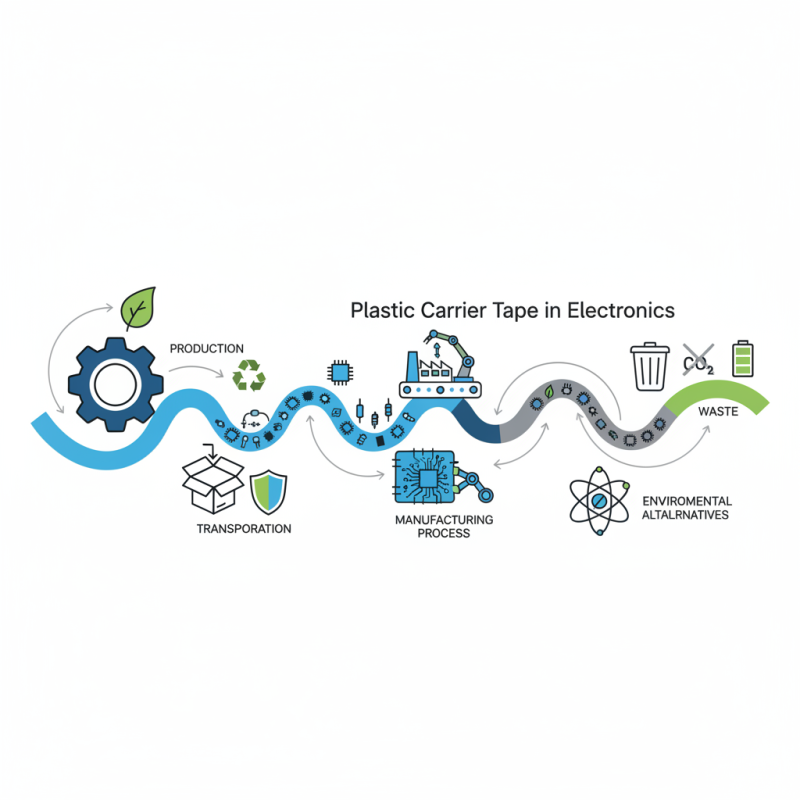

However, challenges exist. The production of Plastic Carrier Tape can have environmental impacts. There is a need for sustainable alternatives to minimize waste. Companies in this industry must reflect on their practices. As they innovate, they should consider both efficiency and sustainability. The future of Plastic Carrier Tape will likely combine high performance with eco-friendly options.

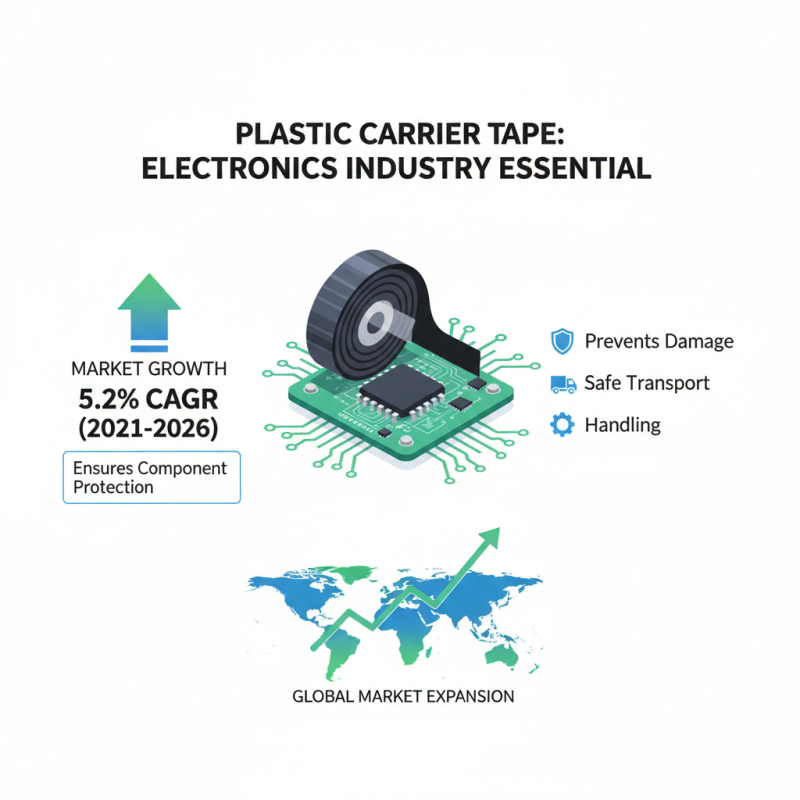

Plastic carrier tape is an essential component in the electronics manufacturing industry. It is designed to hold and transport surface-mount devices (SMDs) safely. This tape ensures that small electronic components remain in place during assembly. It is crucial for high-volume production lines where precision is key. According to industry reports, the global demand for plastic carrier tape is expected to grow by approximately 6% annually.

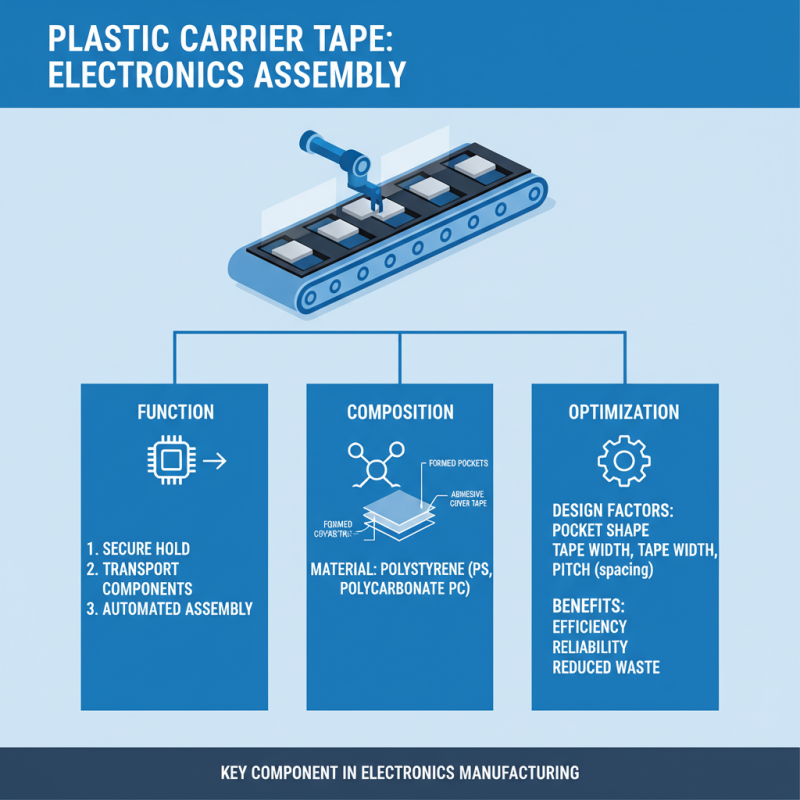

The tape is usually made from materials such as polycarbonate or polystyrene. These materials provide durability and resistance to temperature changes. The design usually includes pockets that securely hold the components. This prevents damage during transport. Companies often report a reduction in defects due to the use of plastic carrier tape. In fact, it’s estimated that using this tape can lower handling errors by up to 30%.

Tips: When selecting plastic carrier tape, consider the type of components you are using. Ensure the pocket size matches the dimensions of your SMDs. Always test the tape in a small batch before full implementation. Check for alignment and fit. This can save time and reduce waste in the long run. Remember, even the best designs can have flaws. Regularly assess your tape quality to avoid potential issues.

| Dimension | Description | Use Case |

|---|---|---|

| Material | Polypropylene or Polyester | Provides durability and flexibility for component handling. |

| Thickness | 0.15mm to 0.5mm | Allows for lightweight designs while maintaining strength. |

| Width | 8mm to 120mm | Accommodates various component sizes for different applications. |

| Hole Size | 1.5mm to 8mm | Ensures precise placement and secure holding of components. |

| Sprocket Hole | Allows for automatic feeding in pick and place machines. | Essential for automated assembly processes and efficiency. |

| Anti-static Properties | Prevents static charge build-up. | Protects sensitive electronic components from damage. |

Plastic carrier tape is a vital component in the electronics manufacturing industry. Its primary role is to securely hold and transport electronic components during assembly. Understanding its composition and structure helps designers optimize its functions.

Typically, plastic carrier tape is made from materials like polypropylene or polyester. These materials provide durability and flexibility. The tape usually incorporates a series of pockets or cavities, precisely designed to fit specific components. The pockets ensure that each part remains in place, reducing the risk of damage during transport. This can be vital, especially for delicate parts like semiconductors.

An essential consideration is the adhesive used on the tape. It must provide enough grip to hold components securely without causing damage. However, finding the right balance can be tricky. If the adhesive is too strong, it may result in difficulties during component removal. On the other hand, if it is too weak, components may dislodge. Designers often need to evaluate their choices and iterate on designs to ensure they meet specific needs.

Plastic carrier tape plays a critical role in the electronics industry. This tape is designed to hold and transport electronic components securely. Its precise features cater to the complex needs of packaging. With a focus on ensuring the safety and integrity of individual parts, this tape prevents damage during transit.

One important function of plastic carrier tape is its anti-static properties. These features are vital for protecting sensitive electronic parts. If exposed to static electricity, components can fail. Thus, using the right packaging is essential for preserving quality.

Tips: Always check the specifications of the carrier tape before use. Ensure it's compatible with your components. Sometimes, not all tapes fit all parts perfectly. Rethink your choices if you notice defects. Pay attention to how the tape adheres to various surfaces. A poor bond can lead to operational issues later on. Focusing on packaging can save significant costs in the long run.

This bar chart illustrates the distribution of market share for plastic carrier tape in various sectors of the electronics industry. It highlights the significant roles that automotive and consumer electronics play in the demand for specialized packaging solutions.

Plastic carrier tape is essential in the electronics industry. This specialized packaging helps ensure that components are not damaged during transportation and handling. According to a recent industry report, the global market for plastic carrier tape is projected to grow at a compound annual growth rate of 5.2% from 2021 to 2026. This growth highlights its increasing importance in various applications.

One common use of plastic carrier tape is in the packaging of surface-mounted devices (SMDs). These devices require reliable transportation to prevent damage. Companies often rely on this tape to keep components securely in place. Another application is in automated assembly lines. The design of the carrier tape allows for efficient feeding into machines, enhancing productivity. Accuracy and speed are critical in this fast-paced environment. However, there is an ongoing challenge with tape compatibility across various machinery.

Moreover, the versatility of plastic carrier tape makes it suitable for different sizes and shapes of electronic components. This adaptability is vital, as electronic designs continue to evolve. While many producers are focusing on sustainable materials, the transition is slow. Concerns about environmental impact linger. It’s crucial for the industry to innovate while keeping efficiency in mind. Balancing these factors will shape the future of plastic carrier tape usage in electronics.

Plastic carrier tape plays a vital role in the electronics industry. The manufacturing process for this tape starts with selecting the appropriate polymer materials. Often, manufacturers use polycarbonate or polyester due to their durability and flexibility. This choice significantly impacts the tape’s performance in various applications.

The extrusion process is essential. It ensures that the carrier tape is produced uniformly with the right thickness. According to recent industry reports, over 70% of companies prioritize precision in this phase. Variability in thickness can lead to misalignment in automated assembly lines. Additionally, the die-cutting technique is critical. It shapes the tape to accommodate different electronic components, such as semiconductors and resistors. Reports note that dimensions can vary by as much as 1 mm, which emphasizes the need for careful measurement.

Quality control is crucial at every stage of production. Inconsistent tape can lead to costly errors in electronics manufacturing. Industry studies indicate that about 15% of defects arise from issues with carrier tape. This statistic highlights the significance of rigorous testing and quality assurance processes. Even minor flaws can disrupt supply chains and affect overall productivity.