Leave Your Message

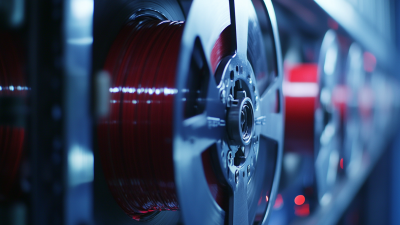

In today’s fast-paced manufacturing landscape, maximizing efficiency is paramount for maintaining competitive advantage, and one innovative solution increasingly adopted is the Carrier Tape Reel. According to industry reports, utilizing carrier tape for component delivery can enhance production efficiency by over 30%, significantly reducing assembly line downtime.

Carrier tape reels are designed to ensure reliable and organized feeding of electronic components, which not only streamlines the assembly process but also minimizes the risk of damaging sensitive parts. Furthermore, a study by the Institute of Electrical and Electronics Engineers (IEEE) indicates that the use of carrier tape reels can lead to a 25% decrease in sourcing and handling costs, making them a vital asset in modern manufacturing operations.

As companies strive for greater productivity and cost-effectiveness, embracing the advantages of carrier tape reels is more critical than ever.

Carrier tape reels are essential components in modern manufacturing, particularly in the electronics industry. They serve as a packaging solution that holds components securely in place for automated assembly processes. The design of carrier tape reels ensures that each item is precisely aligned and easily accessible, enhancing the efficiency of the assembly line. These reels typically consist of a flexible carrier tape with pockets molded to fit specific components, allowing for safe transportation and storage.

When using carrier tape reels, it’s crucial to select the right size and type for your components. This consideration not only minimizes the risk of damage during handling but also ensures optimal sorting and feeding into assembly machines. Tip: Always check the compatibility of your components with the reel specifications to prevent jams and malfunctions during the manufacturing process.

Another key advantage of utilizing carrier tape reels is their role in automating production lines. Automated systems can swiftly and accurately pick components from the reels, significantly increasing throughput. Tip: Regularly monitor the feed mechanism of your machines for any signs of wear or misalignment to maintain smooth operation and reduce downtime. Adopting best practices for the use of carrier tape reels will greatly streamline manufacturing workflows.

In the fast-paced world of manufacturing, efficiency is paramount. One way to achieve this is through the use of carrier tape reels, which play a crucial role in streamlining production processes. These reels help organize and manage components effectively, minimizing downtime during assembly. By utilizing a systematic design, carrier tape reels allow for easy feeding of electronic parts, enhancing workflow and ensuring that workers can access the materials they need without delay.

Moreover, carrier tape reels contribute to improved accuracy in component handling. With a secure and uniform layout, these reels reduce the risk of damage to sensitive electronic parts during transportation and assembly. This reliability not only speeds up production but also decreases material waste, leading to cost savings for manufacturers. Additionally, the ability to automate the feeding process with carrier tape reels means that companies can achieve higher throughput and better overall productivity, perfectly aligning with the goal of maximizing efficiency in the manufacturing environment.

| Advantage | Description | Impact on Production | Typical Applications |

|---|---|---|---|

| Improved Handling | Carrier tape reels facilitate the organized storage and transport of components, reducing the chances of damage. | Reduces waste and increases efficiency in material handling. | Automotive, consumer electronics, and aerospace industries. |

| Space Efficiency | Compact design allows for more efficient use of warehouse and factory space. | Increases overall production capacity by maximizing available space. | Electronics manufacturing and assembly lines. |

| Automation Compatibility | Designed for compatibility with automated pick-and-place machinery for increased speed. | Enhances cycle times and reduces manual labor costs. | High-volume production environments and assembly automation. |

| Standardization | Follows industry standards to ensure compatibility across various equipment and processes. | Simplifies sourcing and inventory management. | Broad manufacturing sectors, including electronics and telecommunications. |

| Reduced Assembly Errors | Minimized risk of component misplacement with organized, sequential arrangement. | Leads to higher quality products and lower return rates. | Final assembly of electronic devices and circuit boards. |

Carrier tape reels are revolutionizing the electronics manufacturing landscape by streamlining the process of component handling and assembly. One of the primary benefits of using carrier tape reels is their ability to enhance organization on the production floor. By providing a systematic and compartmentalized method for storing and feeding electronic components, they significantly reduce the risk of damage and loss. This organized system allows manufacturers to manage a wide variety of components efficiently, thereby minimizing the time spent searching for parts and maximizing production flow.

In addition, carrier tape reels contribute to improved automation in manufacturing processes. When integrated with automated pick-and-place machines, these reels facilitate quick and precise component placement, which is crucial for high-speed assembly lines. This automation not only increases production rates but also enhances accuracy, reducing the likelihood of errors that can arise from manual handling. Ultimately, by incorporating carrier tape reels into their operations, electronics manufacturers can achieve higher efficiency and productivity levels, ensuring they meet the ever-growing demands of the market while maintaining quality standards.

In today's fast-paced manufacturing environment, optimizing supply chain efficiency is paramount. One of the significant innovations contributing to this goal is the use of carrier tape reels. These reels allow manufacturers to package and transport components in a way that minimizes waste and maximizes organization. By securely holding electronic components and other items during transport, carrier tape reels prevent damage and reduce the risk of loss, thus streamlining the supply chain process.

Moreover, the adoption of carrier tape reels leads to substantial cost reductions. With their efficient design, these reels allow for easier handling and automated feeding into assembly lines. This automation not only speeds up production but also reduces labor costs, as fewer workers are needed to manage the feeding and placement processes. The standardization of carrier tapes across the supply chain further enhances compatibility between suppliers and manufacturers, leading to reduced lead times and improved inventory management. As companies seek to cut costs while improving efficiency, the strategic use of carrier tape reels emerges as a smart solution that meets these critical needs.

Carrier tape reels, primarily known for their role in electronic component packaging, are increasingly finding innovative applications beyond traditional manufacturing. One notable area is in the medical field, where carrier tape is utilized to package delicate instruments and devices. This method ensures that each item is securely held in place, reducing the risk of damage during transportation and storage. The use of carrier tape reels enhances the efficiency of medical assembly lines, allowing for rapid access to vital tools while maintaining organization and inventory control.

Additionally, the automotive industry is beginning to adopt carrier tape reels for the assembly of small parts and components. By streamlining the delivery of fasteners, sensors, and other essential elements, manufacturers can minimize downtime and improve production flow. The versatility of carrier tape allows it to accommodate a wide range of shapes and sizes, enabling automotive companies to customize reels for their specific needs. This innovation not only boosts productivity but also contributes to a more sustainable manufacturing process by reducing waste and enhancing material handling.