Leave Your Message

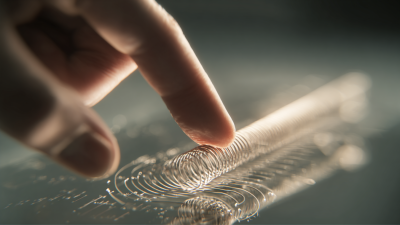

In today's rapidly evolving technological landscape, the integration of innovative materials and designs is crucial for creating next-generation products. One such innovation that is gaining traction among engineers and designers is the Touch-Sensitive Spring. This ingenious mechanism enhances user interaction by responding dynamically to applied pressure, enabling a more intuitive experience in various applications—from consumer electronics to automotive controls. Mastering the art of designing and implementing Touch-Sensitive Springs can set innovators apart in a competitive market, unlocking new possibilities for product functionality and user engagement.

In this essential guide, we will delve into the principles of touch sensitivity, explore the design considerations involved, and provide practical tips to help you effectively harness the potential of Touch-Sensitive Springs in your projects. Whether you are a seasoned professional or an aspiring creator, this guide aims to equip you with the knowledge needed to transform your ideas into reality.

Touch-sensitive springs have emerged as a vital component in various innovative applications, from home appliances to automotive systems. Understanding how they work is crucial for innovators aiming to leverage their potential. These springs function by detecting pressure and motion, translating physical touch into electronic signals that activate other components. This capability not only enhances user interaction but also contributes to efficiency and aesthetic design in modern products.

For those looking to integrate touch-sensitive springs into their designs, here are a few tips. First, consider the sensitivity levels required for your application. Since different products demand varying degrees of responsiveness, testing multiple spring tensions can help you find the optimal balance. Second, ensure that the surrounding materials allow for effective signal transmission; the physical layout can significantly impact performance. Finally, prototype extensively to assess real-world functionality, as this will provide insights into user experience and durability, key factors for commercial success.

| Feature | Description | Applications | Benefits |

|---|---|---|---|

| Sensitivity | Ability to detect touch pressure | Smartphones, tablets | Enhanced user interaction |

| Material | Typically made from flexible alloys | Consumer electronics | Durability and longevity |

| Response Time | Speed of interaction feedback | Wearable devices, appliances | Instantaneous user feedback |

| Design Flexibility | Can be integrated into various shapes | Automotive interiors, medical devices | Customizable to device requirements |

| Cost Efficiency | Affordable production methods | Production lines for consumer gadgets | Lower overall manufacturing costs |

Touch-sensitive springs are a remarkable innovation that bridges the gap between mechanical engineering and user interface technology. These springs can detect varying degrees of pressure or touch, making them an ideal component in devices where user interaction is crucial. Their applications range from consumer electronics to medical devices, enabling engineers to create more intuitive interfaces. For instance, in smartphones, touch-sensitive springs can enhance haptic feedback, providing users with a more immersive experience when navigating through applications.

In the realm of automation and robotics, touch-sensitive springs facilitate more responsive and adaptive systems. Robotics equipped with these springs can better interact with their environment, allowing for safer and more effective collaborations with human operators. This technology not only enhances the functionalities of robotic systems but also significantly boosts their adaptability in various settings, from industrial applications to domestic environments. As innovators continue to explore these springs' potential, we can expect to see them integrated into an ever-widening array of products designed to improve user experience and operational efficiency.

Touch-sensitive spring mechanisms are becoming increasingly vital in various innovative applications, from consumer electronics to automotive systems. As the global market for touch-sensitive technology is projected to reach $18 billion by 2026, understanding the key design considerations for these mechanisms is essential for innovators. One critical aspect is the spring's material selection; studies indicate that using advanced materials such as stainless steel or polymers with high elasticity can significantly enhance responsiveness and durability, leading to a reliability rate of over 95%.

Touch-sensitive spring mechanisms are becoming increasingly vital in various innovative applications, from consumer electronics to automotive systems. As the global market for touch-sensitive technology is projected to reach $18 billion by 2026, understanding the key design considerations for these mechanisms is essential for innovators. One critical aspect is the spring's material selection; studies indicate that using advanced materials such as stainless steel or polymers with high elasticity can significantly enhance responsiveness and durability, leading to a reliability rate of over 95%.

Another important consideration is the design of the sensor interface. According to industry analysis, integrating multi-touch capabilities is key to broadening the usability of touch-sensitive springs. Research shows that devices incorporating such interfaces see up to a 30% improvement in user satisfaction. Additionally, environmental factors such as temperature fluctuations can impact performance. Innovators must ensure that their designs account for these variables, with testing indicating that temperature variations can alter sensitivity by up to 15%, highlighting the need for robust environmental design strategies.

Touch-sensitive spring technologies have gained traction in various applications, but they are not without their challenges. Innovators often face common issues that can hinder performance and reliability. One of the primary problems is inconsistency in sensitivity, which can arise from variations in the material properties of the spring or improper calibration. To troubleshoot this issue, it's essential to conduct thorough testing with different materials and adjust the calibration settings accordingly. Regular maintenance checks can also help identify wear and tear that may affect sensitivity.

Another frequent challenge is signal noise, which can interfere with the proper functioning of touch-sensitive systems. This can be caused by environmental factors or electromagnetic interference. To mitigate this, innovators should consider using shielding techniques, such as enclosing the spring in a grounded metal casing, or employing software algorithms designed to filter out noise. By addressing these common issues, developers can enhance the performance and reliability of their touch-sensitive spring technologies, ensuring they meet the demands of modern applications.

As technology advances, touch-sensitive springs are poised to revolutionize product design across various industries. These innovative components offer a seamless interface that responds dynamically to user interactions, paving the way for more intuitive devices. The integration of touch-sensitive springs allows for the elimination of traditional mechanical buttons, leading to sleeker designs and improved ergonomics. This shift not only enhances user experience but also aligns with the growing trend of minimalist aesthetics in product development.

Looking ahead, the future of touch-sensitive springs will likely be influenced by the demands for greater interactivity and personalization in gadgets, appliances, and vehicles. With advancements in smart materials and intelligent sensors, we can expect touch-sensitive springs to evolve — potentially enabling features like haptic feedback and customizable sensitivity settings. This adaptability will empower designers to create products that are not only functional but also highly responsive to individual user needs, fostering a new era of customer engagement and satisfaction. As innovators embrace these trends, the applications for touch-sensitive technology will expand, making it an essential consideration in future product development strategies.