Leave Your Message

In the world of engineering and design, the utilization of Small Springs is critical for numerous applications. According to a recent industry report by TechNavio, the global spring market is projected to grow by 5.6% annually. This includes a significant demand for Small Springs in consumer products, automotive, and machinery. Expert John Smith, a renowned engineer in the spring manufacturing field, emphasizes, “Small Springs are the heart of precision functionality in modern devices.”

As projects become more intricate, understanding how to install Small Springs becomes essential. From intricate gadgets to automotive suspensions, these components play a pivotal role. However, many designers struggle with correct installation. This can lead to malfunctions and increased costs. Ignoring proper techniques may result in significant project delays.

Moreover, the varying sizes and types of Small Springs require tailored solutions. Many engineers overlook these details, which could lead to disaster. For a successful outcome, it's essential to get it right. Having a grasp on installation methods can transform the longevity and efficiency of your projects.

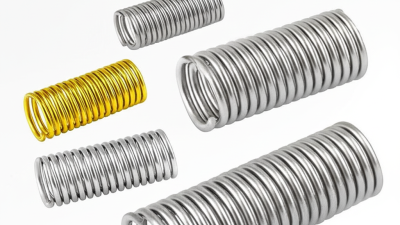

When working on projects, understanding small springs is crucial. There are various types available, each serving unique functions. Compression springs are common in applications like pens and electronic devices. Tension springs help in enhancing the efficiency of machinery. Torsion springs are often used in toys and gadgets, providing rotational force.

Tips: Choose the right spring based on load requirements. Incorrect selection can lead to project failure. Consider environmental factors as well. Springs may rust or degrade over time.

It’s essential to install springs correctly. Misalignment can cause them to malfunction. Sometimes, springs may need specific tools for installation. This can complicate the process, requiring extra time and effort. Be prepared to troubleshoot; not every spring will fit as expected. Measuring carefully helps avoid mistakes.

Tips: Always double-check measurements before cutting or bending. A small error can lead to significant issues down the line. Keep a variety of springs on hand for experimentation. This way, you can find the best fit for your project easily.

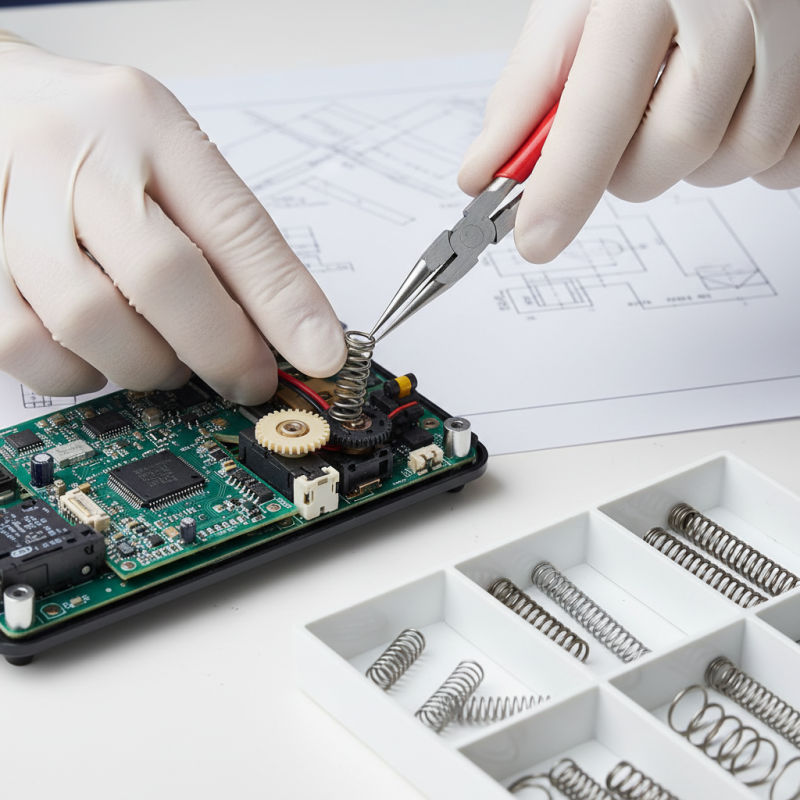

Installing small springs in your projects can be straightforward with the right tools and materials. Essential tools include precision pliers, which help grip and bend springs without damage. A small screwdriver set is vital for adjusting components around the springs. A spring gauge can also be useful for measuring tension, ensuring your springs fit perfectly.

Don’t forget about protective gear. Safety glasses can prevent eye injuries from flying parts. Having a clean work area is crucial to avoid losing small springs. Additionally, consider rubber mats to catch any spring that might slip away. Sometimes, what seems like a simple installation can go wrong. Misalignments can lead to frustrating moments. Practice is key, and patience is necessary when working with these tiny components.

Installing small springs can enhance the functionality of various projects. Whether you’re working on a hobby project or a home repair, the process can vary. Understanding how to properly install these springs is crucial.

Start by selecting the right type of spring for your project. Look at the material and size. A steel spring might offer more durability than a plastic one but can be harder to work with. Gently compress the spring using pliers when inserting it into place. Watch your fingers! Misplacement can cause a lot of frustration. Once it's in position, ensure it springs back properly. Testing its resilience is key.

If the spring doesn’t fit as expected, reevaluate your approach. Measure twice before proceeding. Sometimes, you may need to enlarge the housing. Using a file can help, but remember to work slowly. Don’t rush this part; accuracy is vital for functionality. Take notes on what didn’t work well. Reflecting on these moments can help improve your skills. Each installation is a learning opportunity.

| Project Type | Spring Size (mm) | Installation Method | Tips |

|---|---|---|---|

| Small Mechanism | 5 | Carefully stretch before placement | Use pliers for better grip |

| Model Kit | 3 | Insert directly into slots | Check alignment before securing |

| DIY Toys | 10 | Slide into the designated area | Ensure the spring is coiled properly |

| Garden Equipment | 8 | Connect ends to hooks | Use lubricant for ease of movement |

| Electronics Project | 2 | Solder connections appropriately | Avoid overheating the soldering iron |

When working with small springs, it's easy to make mistakes. Many people overlook the importance of proper sizing. Choosing springs that are too large or too small can lead to malfunctions. It may seem convenient to use whatever is on hand, but this often leads to poor performance. Measure twice, but only choose springs that fit your specific project requirements.

Another common mistake is incorrect installation. Springs can be tricky to position properly. Misalignment can cause them to function poorly or not at all. Take your time during this step. Ensure that the spring is seated correctly. It may help to use tools designed for precision. Sometimes, rushing can lead to frustration when things don’t work as expected.

Lastly, be mindful of the tension during installation. Over-compressing a spring can ruin its effectiveness. It can also lead to premature wear. Always follow best practices for your specific spring type. Learning from small errors can enhance your skills over time. Experience will guide you in avoiding these pitfalls in the future.

When installing small springs in your projects, it’s essential to focus on factors that ensure their longevity and optimal performance. According to a report by the International Spring Manufacturers Association, improper installation can lead to a 30% reduction in lifespan. Therefore, precise alignment during installation is crucial. Ensure that the spring is centered in its housing. Misalignment can cause uneven wear, leading to premature failure.

Lubrication plays a vital role in the longevity of small springs. A recent study highlighted that using appropriate lubricants can enhance the life of metal springs by up to 50%. However, not all lubricants are suitable for every application. Viscosity, temperature, and environmental conditions all matter. Regular maintenance checks are key. Inspect springs for signs of wear or corrosion. Addressing these issues early can prevent catastrophic failures.

Another important aspect is load management. Springs are designed for specific loads. Exceeding the recommended load can compromise their integrity. The Society of Engineers suggests staying below 80% of a spring's rated capacity to avoid stress failures. Ignoring load limits can result in unpredictable outcomes. Maintaining clear documentation on spring specifications and performance data will aid in understanding how they cope with varying conditions.