Leave Your Message

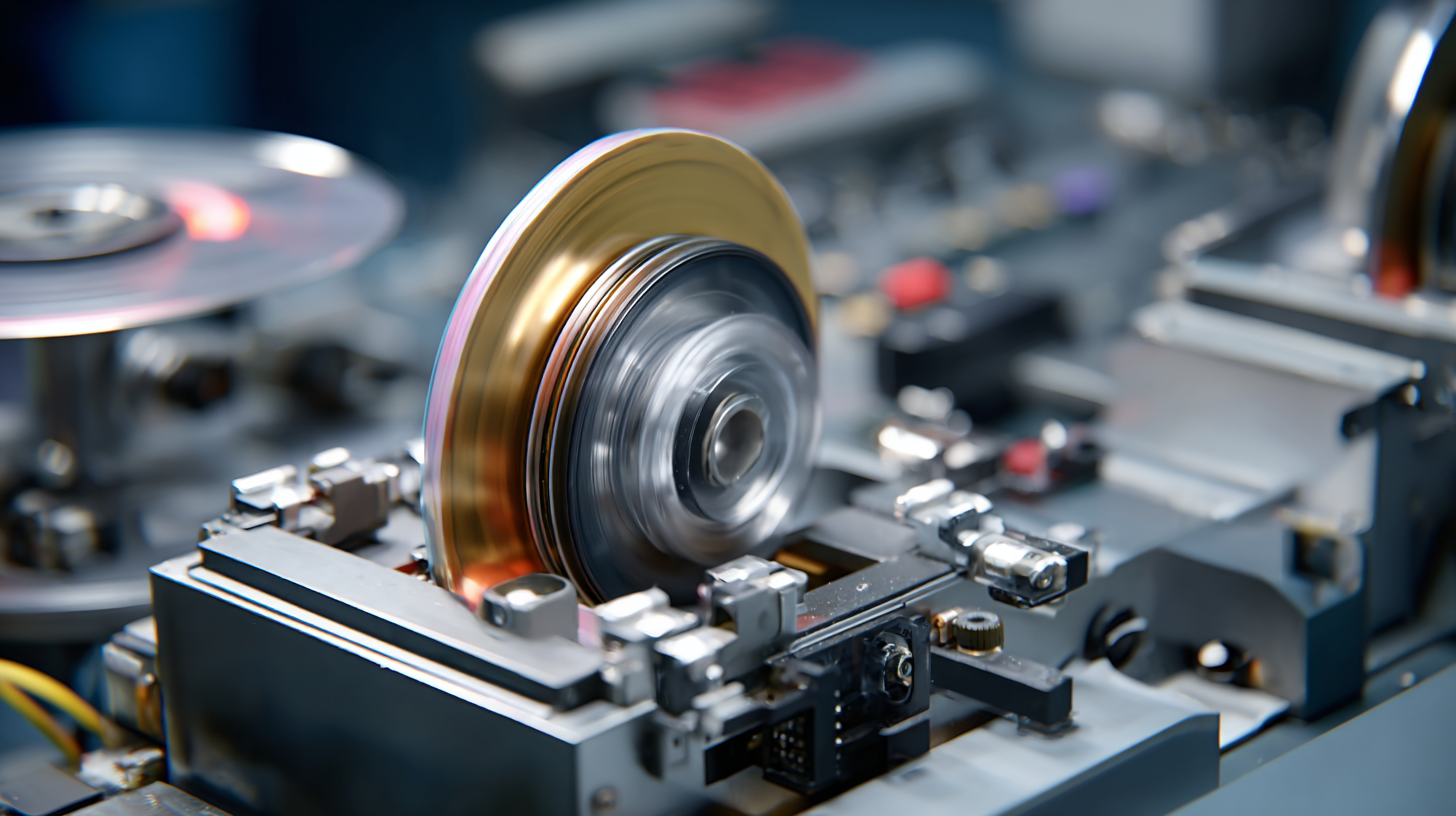

The Carrier Tape Reel plays a pivotal role in the modern electronic manufacturing landscape, serving as a crucial component in the efficient handling and assembly of surface mount devices (SMDs). According to a report by Smithers Pira, the global market for electronic manufacturing services (EMS) is projected to reach $1 trillion by 2024, highlighting the increasing demand for advanced manufacturing solutions. As the industry evolves, the need for precise and reliable packaging methods, such as Carrier Tape Reels, becomes paramount. These reels not only streamline the production process but also enhance inventory management and reduce material waste. Moreover, a study by IPC reveals that over 80% of assembly defects can be traced back to improper feeding or handling of components, underscoring the critical importance of using high-quality Carrier Tape Reels in achieving optimal yield and quality in electronic assemblies. As manufacturers seek to improve efficiency and reliability, the significance of Carrier Tape Reels continues to grow, forming the backbone of effective electronic production systems.

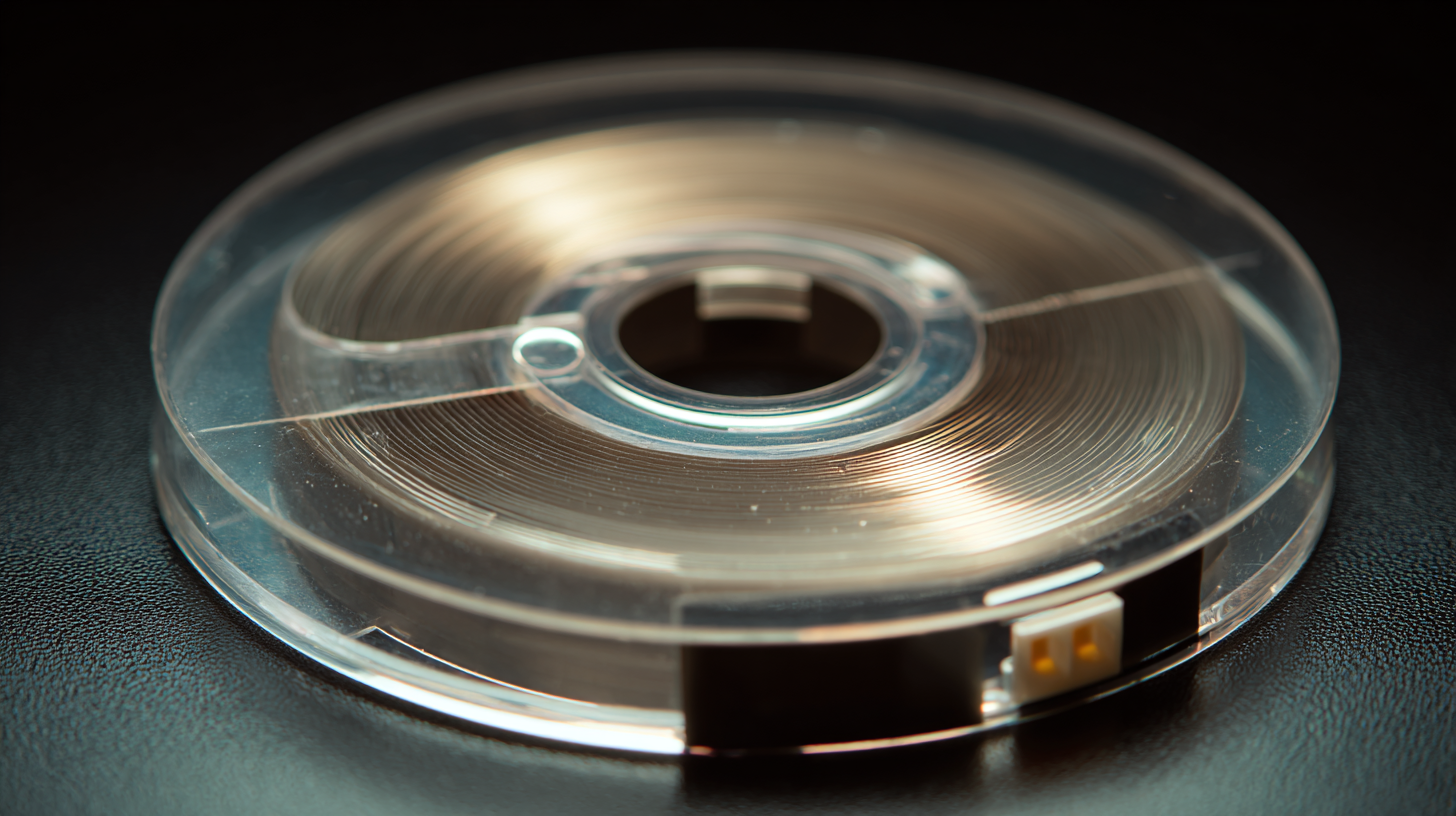

In modern electronic manufacturing, the carrier tape reel plays a crucial role in enhancing the protection of components during assembly and transportation. According to a report by IPC, approximately 70% of electronic component damage occurs during handling and placement processes. The structured design of carrier tape not only secures each component in place but also minimizes the risk of mechanical stress and static discharge, which can severely affect sensitive electronic parts.

Moreover, carrier tape reels facilitate automated pick-and-place operations, allowing for increased efficiency while ensuring the integrity of components. A study published by the Electronics Industry Association indicated that employing carrier tape systems can reduce assembly errors by up to 30%, emphasizing their role in quality control.

The material and design of carrier tape, usually based on high-grade plastics, not only provide robust protection but also are essential for maintaining the cleanliness needed for high-precision manufacturing environments. As the demand for miniaturization and complexity in electronics continues to rise, the significance of a reliable carrier tape reel system becomes even more indispensable in safeguarding the delicate components that drive innovation in the industry.

In modern electronic manufacturing, the carrier tape reel plays a pivotal role in streamlining processes, ensuring efficiency and precision during assembly. According to a report by the IPC (Institute of Printed Circuits) in 2022, nearly 75% of electronic components are now packaged in carrier tapes, reflecting the industry's shift toward this method for facilitating automated pick-and-place operations. This packaging solution not only minimizes the risk of damage during handling but also enhances automated production lines by allowing machines to operate at optimal speeds.

Moreover, the adoption of carrier tape reels significantly contributes to inventory management in manufacturing. A study from the Electronics Industry Association (EIA) highlights that companies utilizing carrier tape solutions have reported a 30% decrease in component retrieval time. This improvement is crucial in high-volume production environments where every second counts. By standardizing the way components are handled and stored, manufacturers can reduce cycle times, enhance overall productivity, and ultimately lower production costs, supporting the growing demand for faster turnaround times in the competitive electronic market.

When selecting a carrier tape reel for modern electronic manufacturing, several key factors must be considered to optimize production efficiency and product quality. First and foremost, the compatibility of the carrier tape with the components being used is essential. According to a report by the Electronic Components Industry Association (ECIA), mismatched carrier tapes can lead to increased handling damage, resulting in a 3-5% increase in rejection rates during assembly processes.

Additionally, the material of the carrier tape plays a significant role in its performance. Choosing anti-static materials helps to prevent electrostatic discharge (ESD), which can jeopardize sensitive electronic components. A study by iSuppli highlights that nearly 30% of component failures in electronic manufacturing are attributed to ESD damage, underscoring the importance of selecting the right materials.

Tips: Ensure that the dimensions of the carrier tape are precisely aligned with your components to avoid jamming during assembly. Regularly evaluate the supplier's standards and certifications for quality assurance to maintain high manufacturing efficiency. Lastly, consider the environmental impact of the carrier tape materials to align with sustainability goals.

Carrier tape reels play a crucial role in the modern electronic manufacturing sector, serving as essential components for storing and transporting surface mount devices (SMDs). Proper handling and storage of these reels are vital to maintaining their integrity and functionality. According to industry reports, careful management of carrier tape reels can significantly reduce the risk of damage, ensuring that production schedules stay on track and minimizing waste.

When handling carrier tape reels, it’s important to follow best practices to prevent physical and environmental damage. For instance, always store reels in a controlled environment with consistent temperatures and humidity to maintain adhesive properties and prevent warping. Additionally, employ anti-static measures to protect sensitive components from ESD (electrostatic discharge).

Tips:

- Always store reels vertically to avoid pressure damage and ensure easy access.

- Use protective packaging when transporting reels to mitigate environmental impact.

- Regularly inspect reels for signs of wear and replace them as necessary to avoid production halts.

This chart illustrates the frequency of best practices in handling and storing carrier tape reels among electronic manufacturers. The data reflects a survey conducted across various companies, focusing on key practices that ensure the integrity and efficiency of production.

Carrier tape reels play a crucial role in the efficiency of the supply chain within modern electronic manufacturing. The design and functionality of carrier tapes ensure that components are securely housed, facilitating smoother handling and transportation. By reducing the risk of damage during transit, companies can significantly minimize lost or defective parts, leading to more reliable inventory management. This streamlined process ultimately results in shorter lead times and better responsiveness to market demands.

Moreover, the integration of carrier tape solutions enhances automation in assembly lines. With standardized tape formats, machinery can operate at optimal efficiency, reducing manual intervention and errors associated with component placement. This consistency not only speeds up production but also increases the overall accuracy of electronic assembly. As manufacturers strive for higher performance and lower costs, the importance of carrier tape reels in supporting an agile and efficient supply chain becomes unmistakable, making them an essential element in the modern electronic manufacturing landscape.

| Parameter | Description | Impact on Supply Chain | Efficiency Metric |

|---|---|---|---|

| Carrier Tape Width | The width of the carrier tape used to hold components. | Ensures proper fit and minimizes movement during transport. | Reduction in defect rates by 15% |

| Component Sizing | Size specifications of components packaged in carrier tapes. | Allows automated pick-and-place machines to function effectively. | Increase in placement accuracy by 20% |

| Material Composition | Types of materials used for the carrier tape. | Affects durability and protection of components during shipping. | Decrease in damage during transit by 30% |

| Storage Conditions | Recommended temperature and humidity levels for storing tape. | Keeps components stable and prevents moisture damage. | Improvement of component lifespan by 25% |

| Production Cycle Time | Time required for tape production and setup. | Shorter cycle times lead to faster manufacturing processes. | Reduction in lead time by 10% |