Leave Your Message

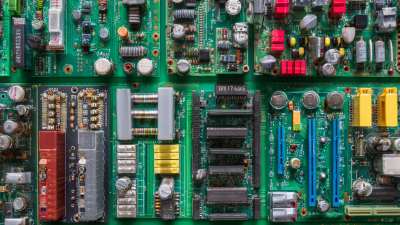

In today's rapidly evolving electronics landscape, sourcing PCB Printed Circuit Boards (PCBs) globally has become an essential strategy for manufacturers seeking quality, cost-effectiveness, and innovation. According to a recent report by MarketsandMarkets, the global PCB market is projected to reach USD 75.98 billion by 2026, growing at a CAGR of 4.2% from 2021. This growth underscores the increasing demand for high-performance PCBs utilized in diverse applications, including automotive, consumer electronics, and telecommunications. However, navigating the complexities of global sourcing demands a comprehensive approach that addresses factors such as supplier reliability, quality assurance, and logistical challenges. Our ultimate checklist serves as an invaluable resource for businesses looking to streamline their PCB procurement process while adhering to industry standards and enhancing their competitive edge.

Understanding the global PCB sourcing landscape requires a keen awareness of current industry trends and insights. According to a 2022 industry report by Technavio, the global PCB market is expected to grow by over $15 billion from 2022 to 2026, driven by the increasing demand for electronic devices across various sectors, including automotive, aerospace, and consumer electronics. This growth underscores the importance of strategic sourcing practices as companies seek to optimize costs while maintaining quality and reliability in their products.

Another significant trend in PCB sourcing is the shift towards sustainability and environmentally friendly materials. Research by IPC — Association Connecting Electronics Industries indicates that nearly 70% of manufacturers now prioritize eco-friendliness in their materials and processes, reflecting a growing consumer preference for sustainable products. Additionally, the adoption of advanced technologies like AI and IoT in manufacturing processes is enhancing supply chain efficiency, with 75% of companies reporting significant improvements in lead times and inventory management as a result of these innovations. Recognizing and adapting to these dynamics is crucial for businesses aiming to stay competitive in the rapidly evolving PCB landscape.

When considering sourcing PCB (Printed Circuit Boards) internationally, three key factors come into play: cost, quality, and expertise. First, let's talk about cost. Sourcing PCBs from countries with lower labor and production costs can substantially reduce overall expenses. This cost efficiency not only improves profit margins but also allows companies to allocate resources to other critical areas such as research and development or marketing. By leveraging global supply chains, businesses can achieve significant savings that can define their competitive edge in the market.

Quality is equally paramount when sourcing PCBs. Many international suppliers are renowned for their advanced manufacturing techniques and stringent quality controls. Countries like Taiwan and China have become leaders in PCB production, providing high-tech solutions and achieving consistent reliability. Collaborating with these suppliers not only ensures high standards but also enhances product performance, thereby boosting customer satisfaction.

Finally, expertise is a crucial advantage that international sourcing offers. Many countries specialize in specific types of PCB technology, from flexible circuits to high-frequency boards. Accessing this niche expertise can lead to innovative designs and advanced functionalities that may not be readily available in local markets. This global perspective can help companies stay ahead of technological trends, driving innovation and competitiveness in the ever-evolving electronics landscape.

When sourcing PCB suppliers globally, several essential factors must be taken into account to ensure quality and efficiency. First and foremost, evaluating the supplier's manufacturing capabilities is crucial. Potential partners should have advanced technology and equipment to meet diverse production needs, from high-volume manufacturing to specialized requirements. A strong track record in quality control and compliance with international standards is also vital, as the reliability of PCBs directly impacts the performance of electronic devices.

Another important aspect is the supplier's experience and responsiveness. Companies that have been in the industry for a significant period often have the knowledge to navigate various challenges, such as supply chain disruptions and fluctuating material costs. Quick service response times can significantly reduce downtime during production, ensuring that projects remain on schedule. Furthermore, considering a supplier's geographical location can play a role in logistics and shipping times, which may affect costs and overall efficiency in meeting market demands. By carefully weighing these factors, businesses can make informed decisions when selecting PCB suppliers in the competitive global market.

When sourcing PCB printed circuit boards globally, understanding and navigating regulatory compliance is paramount. Different countries have their own specific regulations that govern electronics manufacturing, importation, and safety standards. Failure to comply with these regulations can lead to significant financial penalties, product recalls, or supply chain disruptions. Therefore, it’s crucial to stay informed about the legal landscape in the countries from which you are sourcing.

Tip: Conduct thorough research on international certifications such as RoHS, CE, and UL, which may be required for your PCB products. Ensure your suppliers are well-versed in these regulations and can provide documentation to verify compliance. This not only mitigates risks but also enhances your credibility with customers.

Another key aspect is understanding the tariffs and trade agreements that may affect sourcing costs. Many regions, including the EU and Asia, have specific trade rules that can impact import duties. Being aware of these can help you optimize your sourcing strategy for cost-effectiveness.

Tip: Utilize trade compliance consultants or software tools to track these regulations and stay updated with changes. This proactive approach can save time and ensure your sourcing process aligns with both domestic and international laws, ultimately leading to smoother operations.

When sourcing printed circuit boards (PCBs) from international manufacturers, effective communication is paramount. According to a report by the IPC (Association Connecting Electronics Industries), miscommunication can lead to a staggering 30% increase in production costs due to errors and rework. Designing a clear communication strategy that encompasses technical specifications, timelines, and expectations is crucial for maintaining both quality and efficiency in the production process. Utilizing tools like detailed project briefs and standardized communication templates can help streamline the interaction and minimize misunderstandings.

Moreover, cultural differences play a significant role in international PCB sourcing. A survey conducted by the Electronics Industry Association found that 58% of companies experienced challenges stemming from differing business practices and communication styles. To navigate these challenges, it’s essential to invest in cultural training for team members and establish a communication protocol that respects these differences. For instance, being aware of response times, negotiation tactics, and the preferred modes of communication can greatly enhance relationships with overseas manufacturers, facilitating smoother transactions and fostering long-term partnerships.

| Criteria | Details | Importance Level |

|---|---|---|

| Manufacturing Capabilities | Evaluate the production technology and types of PCBs produced (e.g., single-sided, double-sided, multilayer). | High |

| Quality Certifications | Check for ISO 9001, IPC-A-600, and other relevant certifications. | High |

| Lead Time | Assess the average time required from order confirmation to delivery. | Medium |

| Cost Estimation | Request detailed quotes with breakdowns of material, labor, and shipping. | High |

| Communication Channels | Determine preferred communication methods (email, chat, calls) and language proficiency. | Medium |

| Sample Evaluation | Request samples to assess workmanship and functionality before placing bulk orders. | High |

| Warranties and Support | Inquire about warranty terms and post-sale support services. | Medium |

| Cultural Awareness | Understand cultural differences that may affect business interactions. | Low |