Leave Your Message

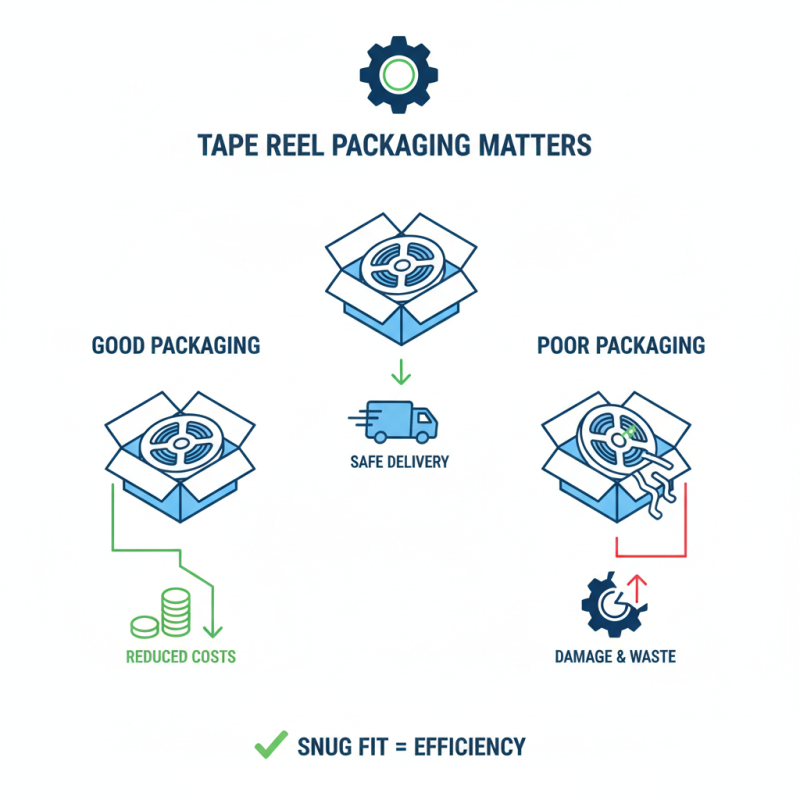

Tape Reel Packaging is a critical aspect of the manufacturing and distribution process. Smooth and efficient packaging saves time and reduces costs. Dr. Emily Thomson, an industry expert, once said, "Proper tape reel packaging can make or break a product’s success." Her insight highlights the importance of mastering this technique.

In a world of ever-increasing demand, many businesses overlook the finer points of tape reel packaging. This can lead to damaged products and dissatisfied customers. Effective techniques include appropriate reel size, proper alignment, and secure sealing. Each step may seem small, yet they significantly impact the end result.

Quality materials also play a role. Cheap tape may fray or fail. The right choices ensure products arrive intact. Attention to detail in packaging reflects on the brand’s overall image. Striving for perfection in tape reel packaging can be challenging. Companies often find themselves making the same errors repeatedly. Reflecting on past mistakes can lead to better processes and improved outcomes. In the end, it’s about enhancing the customer experience through thoughtful packaging.

Tape reel packaging is a crucial aspect of manufacturing. It ensures that components are delivered safely and efficiently. Effective packaging can prevent damage during shipping, reducing costs. Ideally, each reel should fit snugly in its packaging. Loose reels can lead to tangling and wastage.

Understanding the nuances of tape reel packaging is essential. Properly labeled reels speed up the production process. Workers waste less time searching for components. Clear labels help everyone on the assembly line. Yet, many manufacturers overlook this detail, leading to confusion. Using standardized sizes can streamline operations. However, companies often stick to outdated methods, missing the chance for improvement.

Improving tape reel packaging requires continuous evaluation. Are the materials durable enough? Do they meet industry standards? Reflecting on these questions can lead to better practices. All of this contributes to smoother production flows. Simple adjustments can have significant impacts. A small investment in proper packaging could yield great returns in efficiency and reliability.

Choosing the right materials for tape reel packaging is crucial. The material affects durability, protection, and shipping costs. Common choices include cardboard, plastic, and foam. Each type has unique properties to consider.

When preparing tape reels for packaging, each step requires careful attention. Start by gathering all necessary materials. Make sure the reels are clean and free from dust. Inspect each tape reel for any signs of damage. If you notice bends or tears, set those aside. They may not hold up during transit.

Next, secure the tape reels tightly. Use appropriate material to prevent movement. This may include bubble wrap or foam. Wrap each reel individually. Ensure they are snug but not overly tight. Test the packaging by gently shaking it. If you feel movement, rewrap the tape.

Remember to label your packages clearly. Use markers or labels that won’t smudge. It’s easy to overlook this step, but it helps greatly. Keep the labels simple. Include contents and handling instructions. A simple note can save time later.

One could argue packaging might seem trivial, but it's crucial. You need to reflect on potential improvements. Examine past packaging failures and learn from them. This is the path to better practices. Small tweaks can significantly enhance the process.

| Step | Description | Materials Required | Duration |

|---|---|---|---|

| 1 | Gather all necessary materials for packaging. | Tape reels, boxes, packing peanuts, bubble wrap, tape. | 30 mins |

| 2 | Inspect tapes for any defects before packaging. | Inspection tools, checklist. | 15 mins |

| 3 | Carefully wrap each tape reel with bubble wrap. | Bubble wrap, scissors. | 20 mins |

| 4 | Place the wrapped reels into boxes with packing peanuts for protection. | Boxes, packing peanuts. | 25 mins |

| 5 | Seal boxes securely using packaging tape. | Packaging tape, tape dispenser. | 10 mins |

| 6 | Label each box with the necessary shipping information. | Label printer, shipping labels. | 15 mins |

Properly securing and labeling tape reels is essential for efficient storage and usage. Start by choosing appropriate packaging materials. Use sturdy plastic or cardboard boxes that prevent damage during transit. Tape reels should fit snugly to avoid movement. This reduces the risk of tangling or breaking.

Labeling is equally important. It helps in quick identification and retrieval.

When labeling, include key information like type, length, and usage instructions. Use clear, legible fonts for easy reading. Position labels in a consistent spot on every reel. This uniformity aids in organization. You might consider using color-coded labels for different types of tape, adding a visual cue for faster recognition.

Don’t overlook the importance of regular audits. Check your inventory periodically to ensure proper organization. Reflect on past experiences, like misplacing reels due to poor labeling. Learning from these mistakes is key. Sometimes, a simple solution lies in revisiting your packaging techniques. Simple tweaks can dramatically improve efficiency and reduce errors. Keep evolving your methods for better results.

When it comes to tape reel packaging, small mistakes can lead to big issues. One common error is using inadequate materials. Low-quality tape can fail during transit, exposing your product. Always choose durable tape that can withstand various conditions. Additionally, ensure that the reel is securely fastened. Loose reels can cause tangling, damaging the contents.

Another frequent mistake involves improper alignment of the tape. Misaligned tape not only looks unprofessional but can also jeopardize product integrity. Take the time to measure and center the tape properly. Rushed packaging can lead to uneven distribution of pressure. This may result in the tape tearing or failing to hold.

Overpacking is also a pitfall to avoid. While it might seem safer to add more protection, using excess tape can make it difficult to unpack. It creates additional waste and can frustrate the end-user. Effective tape reel packaging should balance security and accessibility. Aim for efficiency in every step, from selection to application.