Leave Your Message

Selecting the right plastic carrier tape can be a daunting task. With various options available, understanding your specific needs is crucial. Plastic carrier tape plays a vital role in the efficiency of your production process. It can influence both the quality and speed of your operation.

When choosing plastic carrier tape, consider the materials it will support. Factors like thickness, width, and adhesive type matter. Each choice can significantly impact your workflow. Sometimes, users think they need one type, only to find it unsuitable later. This realization can delay projects and inflate costs.

Pay attention to the environment where the tape will be used. Temperature, humidity, and exposure to chemicals can affect performance. Reflecting on these details early on can save time and resources in the long run. Making an informed choice is essential for achieving optimal results.

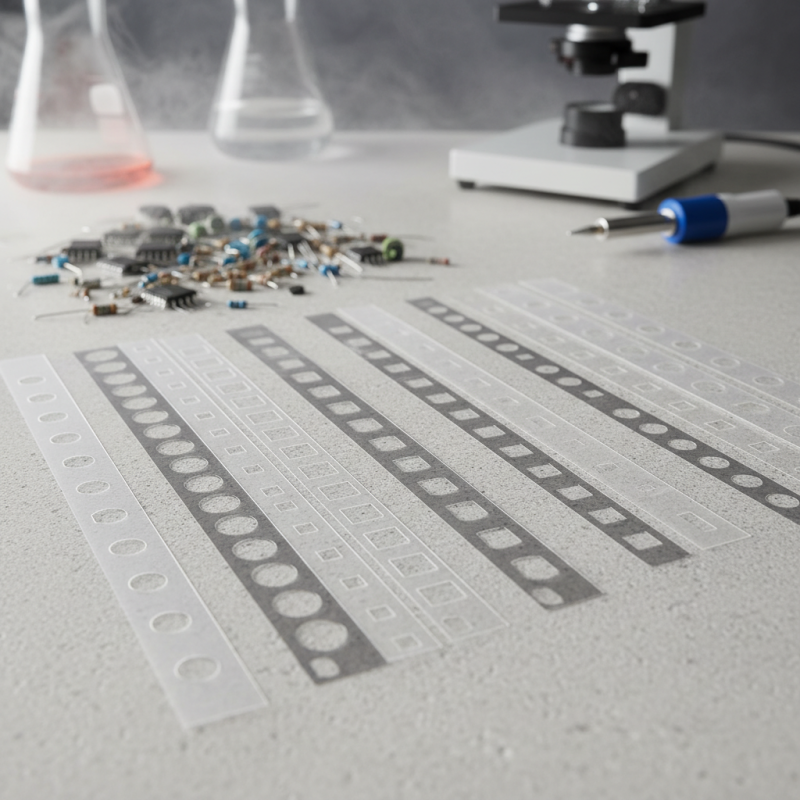

When choosing plastic carrier tape, it's essential to understand the different types available. Plastic carrier tapes can vary in material, thickness, and adhesive properties. Some are made from polyester, while others use polyimide. Each type serves different applications in packaging and electronics.

Understanding your specific needs is key. For example, if you need a tape that withstands high temperatures, consider polyimide tapes. They offer better thermal resistance than polyester tapes. If the goal is to secure lightweight materials, a thinner polyester tape may suffice.

**Tips**: Test multiple options before settling on one. A small sample can reveal how the tape adheres under various conditions. Consider environmental factors like humidity and temperature. Additionally, look for user reviews. They often highlight potential issues that may not be evident initially. Remember, not every tape works for every situation. Always be open to adjusting your choice based on results.

| Tape Type | Material | Thickness (mm) | Width (mm) | Application | Temperature Resistance (°C) |

|---|---|---|---|---|---|

| Standard Carrier Tape | Polypropylene (PP) | 0.15 | 12 | SMT Components | -20 to 80 |

| Embossed Carrier Tape | Polycarbonate (PC) | 0.20 | 16 | LED Components | -20 to 85 |

| Conductive Carrier Tape | Polypropylene with Conductive Coating | 0.18 | 8 | ESD Sensitive Components | -10 to 75 |

| Custom Carrier Tape | Varied | Custom | Custom | Special Applications | Varied |

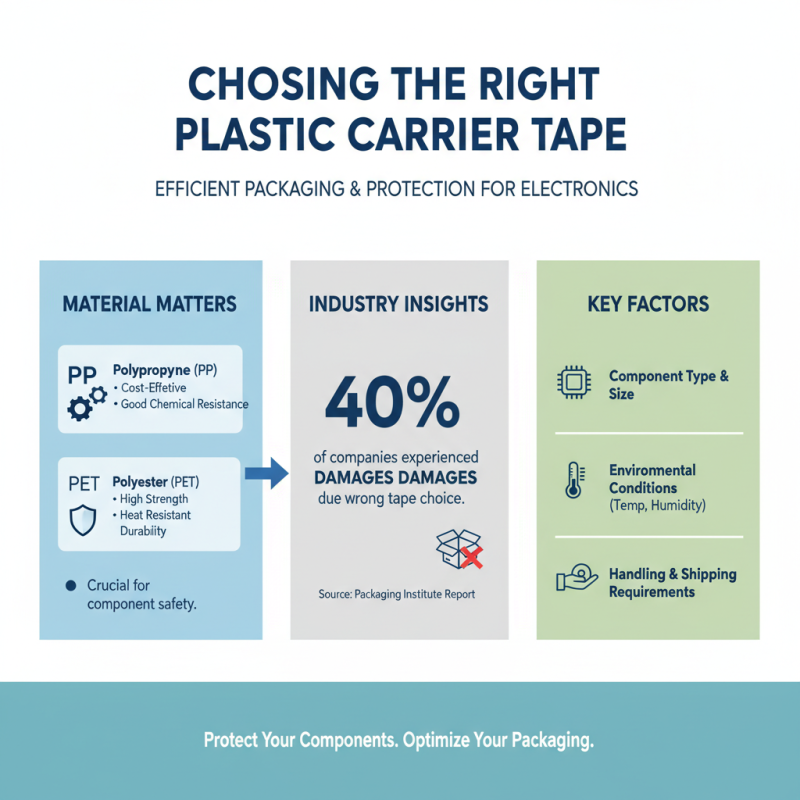

Choosing the right plastic carrier tape is crucial for efficient packaging and protection of electronic components. One key factor is the tape's material. Polypropylene and polyester are common choices. Each offers different levels of resistance and flexibility. A report by the Packaging Institute states that over 40% of companies experienced damages due to the wrong tape choice.

The dimensions of the carrier tape are equally important. Width and depth specifications can determine compatibility with your machinery. A mismatch can lead to production delays and increased costs. In fact, a study found that improper tape dimensions contribute to a 25% increase in operational inefficiencies.

You should also consider the tape's anti-static properties. In sensitive electronic applications, static can degrade components. Ensuring your carrier tape has suitable electrostatic discharge (ESD) capabilities can prevent potential losses. Many experts recommend conducting tests on samples to evaluate performance in real-world conditions. Experimenting with different types may reveal unforeseen issues, helping refine your final choice.

Choosing the right plastic carrier tape begins with understanding component compatibility. Different components require specific materials for optimal performance. For instance, electronic components often need antistatic tapes to avoid surface damage. Industry reports emphasize that the wrong tape can lead to product failures, affecting production lines and costs.

Tip: Assess your components’ compatibility before selection. Review specifications, such as temperature and chemical resistance. This can help prevent costly mistakes.

It is crucial to consider the size and structure of your components. Carrier tapes must match component dimensions closely. Industry standards suggest a tolerance of ±0.5 mm for efficient function. A mismatch may cause jams or misalignment during manufacturing.

Tip: Conduct a test run with samples. Testing ensures that the selected tape works well with your machinery and components. This step can save time and resources.

When selecting a plastic carrier tape, considering environmental and storage conditions is crucial. The tape must withstand various temperatures, humidity levels, and exposure to elements. High temperatures can lead to distortion, while excessive humidity may weaken adhesion. Assess your storage environment to ensure it aligns with the tape's specifications. A cold, dry place is typically ideal.

Think about the specific items you will be storing or transporting with the tape. Some materials may require special types of adhesive. Not all tapes perform equally under pressure or extreme conditions. Consider testing samples in your actual environment. It can reveal potential weaknesses.

Improper choices may result in costly damage or delays. Notice how often you need to replace tape due to environmental failures. Regular evaluation can improve your decision-making process. Be open to revisiting your choices as conditions change. Quality and durability can vary, and learning from past experiences is essential.

When analyzing cost and supplier options for plastic carrier tape, it’s crucial to explore your specific needs. Consider the material type, thickness, and length of the tape required. Different projects will demand varied specifications. Quality often impacts cost. Cheaper options may lack durability. Evaluate the craftsmanship behind each type of tape.

Tips: Always ask for samples before committing to bulk orders. Test several options on your materials to find the best fit. Quality assurance can make or break your project.

Supplier options are plentiful, but not all are reliable. Some suppliers might promise fast delivery but fail in quality. Look for reviews and feedback from others in your industry. Don't shy away from negotiating prices. A good supplier should be open to discussions. Aim for long-term relationships, as they can yield better pricing over time.

Tips: Prioritize suppliers who understand your needs. Post-purchase support is vital. If problems arise, a responsive supplier can save you headaches later. Stay informed about market trends to avoid overpaying.