Leave Your Message

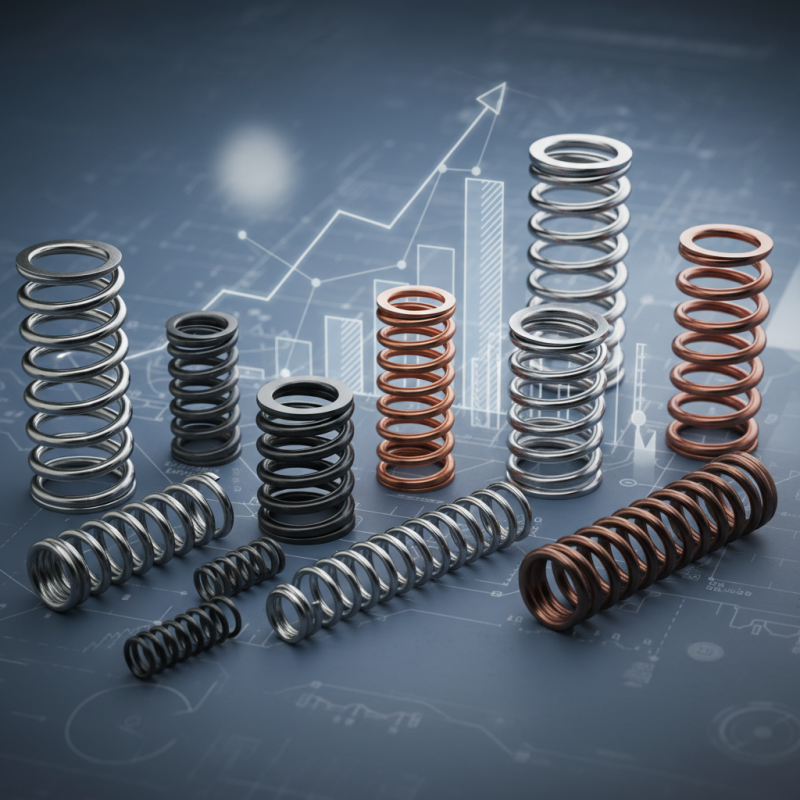

Choosing the right Helical Touch Spring is crucial for various applications. According to a recent industry report, the Helical Spring market is projected to grow by 5% annually. This growth highlights the demand for more specialized and durable spring solutions. As noted by Dr. Emily Carter, a leading expert in the field, "Understanding the unique needs of your application is vital when selecting a Helical Touch Spring."

Each spring type offers unique characteristics. It's important to consider factors like material, dimensions, and load requirements. Too often, companies overlook these details, leading to costly errors. A well-chosen Helical Touch Spring can improve performance and longevity. However, misjudgments in specifications can lead to mechanical failures.

Investing time in detailed research pays off. Engaging with industry professionals can provide valuable insights. Yet, many still choose based on assumptions rather than data. It’s important to question if you have the right knowledge before making a decision. In this evolving market, aligning choices with expert recommendations is key to success.

Helical touch springs are crucial in various applications. They provide tactile feedback, which is important in devices like keyboards and touchscreens. These springs work by storing energy and releasing it when pressed, giving users a satisfying click. A good understanding of their function can enhance user experience significantly.

According to industry reports, the global market for touch springs is expected to grow steadily, driven by increased demand in consumer electronics. The precision of these springs impacts their performance. For instance, the coil's diameter and wire size have direct effects on resistance and flexibility. Adjusting these factors can result in different tactile sensations, which may not always meet user expectations.

Selecting the right helical touch spring can be a challenge. Not all springs deliver the same performance. Some may feel too soft or hard. Understanding the application and desired feedback is essential. A mismatch can lead to user dissatisfaction. Testing various designs may be necessary to find that perfect fit. Adjustments might lead to learning curves.

When selecting a helical touch spring, several key factors require careful consideration. The material is crucial as it directly influences performance. Steel is commonly used, but other materials may offer better corrosion resistance or durability. According to industry reports, more than 40% of spring failures are due to material fatigue. Knowing your application's environmental conditions helps in making the right choice.

Another important aspect is the spring's dimensions and load capacity. Helical touch springs come in various sizes. Ensure that you match the spring's free length and outside diameter to your specific needs. Research indicates that a miscalculated load can lead to a 30% decrease in performance efficiency. Pay attention to the spring's rate, as this defines how much it will compress under a specific load.

Coiling direction is a detail often overlooked. It affects installation and overall performance. Industry experts note that improper coiling can lead to unexpected failure modes. Assess your application carefully; avoid relying solely on standard specifications. Each application is unique, and taking the time for precise measurements will pay off in the long run.

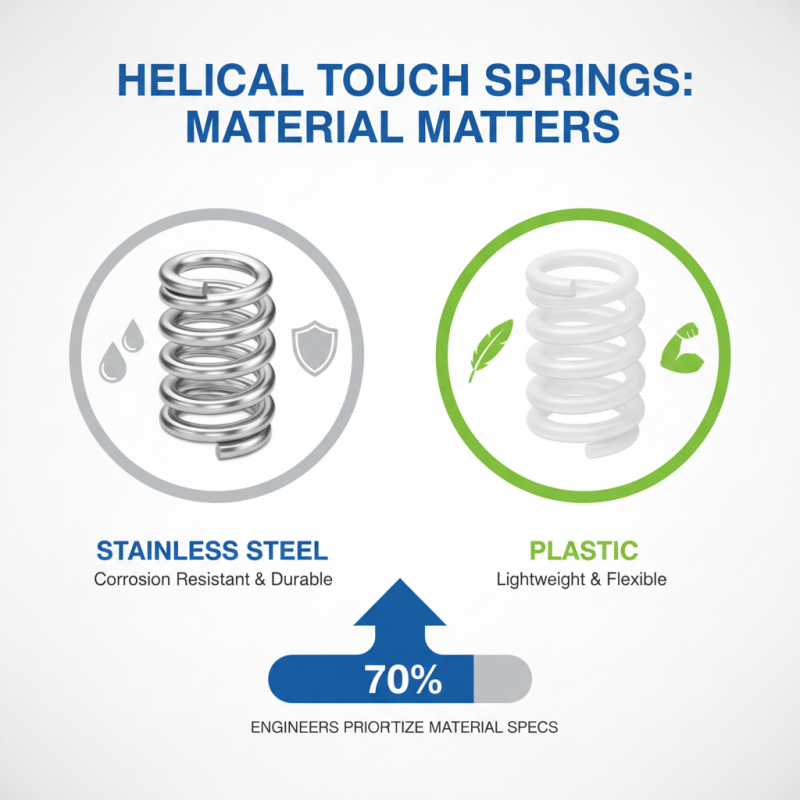

When selecting helical touch springs, material choice is vital. Different materials offer varying performance qualities. Stainless steel is known for its corrosion resistance and durability, making it a popular choice. In contrast, plastic springs can reduce weight while providing sufficient flexibility. Research indicates that nearly 70% of engineers prioritize material specifications in their design decisions.

Copper alloys can be beneficial as well. They deliver excellent conductivity and elasticity but may not withstand extreme temperatures. It’s essential to assess the application conditions, including temperature fluctuations and environmental impacts, to make an informed choice. A study showed that improper material selection led to a 30% increase in failure rates in certain applications.

While many focus on immediate performance, long-term implications should not be overlooked. For instance, a spring made from a less durable material might fail prematurely, requiring replacements and incurring costs. The life cycle of the material is a crucial factor that often gets inadequate attention. Choosing the right material could save both time and resources in the long run.

When selecting a helical touch spring, sizing and load capacities are crucial. The right size ensures functionality. A spring's diameter and length significantly affect its performance. Industry reports indicate that improper sizing can lead to a 30% increase in failure rates. It's not just about fitting the space. The load capacity must be matched to the application.

Factors like wire diameter play a key role. Choosing a wire that is too thin may cause premature wear. Conversely, a wire that is too thick may lead to excessive tension. Balance is essential. Studies show that springs operating at 80% of their rated load tend to last longer. This highlights the importance of precise calculations. Many engineers overlook the need for accurate load assessment, which can lead to costly mistakes.

Spring dynamics are complex. Temperature changes can affect load capacity. Even slight fluctuations can alter performance. A report from the Engineering Society highlights that nearly 15% of failures are linked to environmental factors. This is a reminder that situational awareness is critical. Users should revise their choices based on application needs. Take time to assess how each element influences the overall design. Understanding these factors can lead to better outcomes and avoid pitfalls.

Helical touch springs are essential in various industries. They provide reliable force in applications like automotive, aerospace, and consumer electronics. In automotive design, they support project components, ensuring smooth operation under stress. In aerospace, they help maintain critical systems' integrity, especially where precision is key.

Tips for choosing the right one: Consider the load and stress conditions. You might think a thicker spring is always better. Sometimes, that’s not the case. A spring that's too stiff can lead to premature failure.

In consumer electronics, these springs enhance user experience. They provide tactile feedback in devices like smartphones or remote controls. Many users appreciate the responsiveness. However, the wrong spring may cause discomfort. It's crucial to test prototyped devices to find the best fit. Pay attention to user feedback and make adjustments accordingly. This iterative process helps refine the product.