Leave Your Message

Choosing the right Touch Button Spring for your device can be challenging. It requires careful consideration of various factors. These springs impact the overall functionality and feel of your device. A well-chosen spring ensures a responsive and satisfying user experience.

Different devices have unique requirements for their touch button springs. Sizing, tension, and material are all important elements. Picking a spring that fits poorly can lead to frustration. If the spring is too stiff, it may hinder operation. If it's too soft, it may lack responsiveness.

In many cases, users overlook the significance of this component. It’s easy to assume any spring will work. However, the wrong choice may cause your device to malfunction. It’s crucial to reflect on the implications of this decision. A thoughtful approach will pay off in the long run.

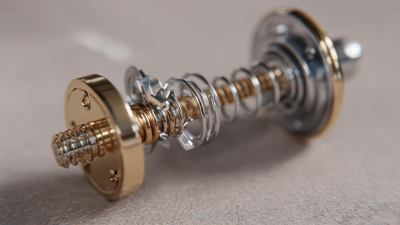

When selecting touch button springs, understanding their types and materials is crucial. There are various kinds of springs, such as metal coil springs and elastomer springs. Metal coil springs offer durability and a robust feel, making them suitable for high-usage devices. In contrast, elastomer springs provide a softer touch. They can be quieter and require less force to actuate.

Materials play a vital role too. Stainless steel springs resist corrosion, ensuring longevity in demanding environments. Likewise, spring materials must match the device's use. A device exposed to moisture needs specific materials to prevent wear. For some, cost considerations might prioritize cheaper materials, leading to easier wear and reduced lifespan.

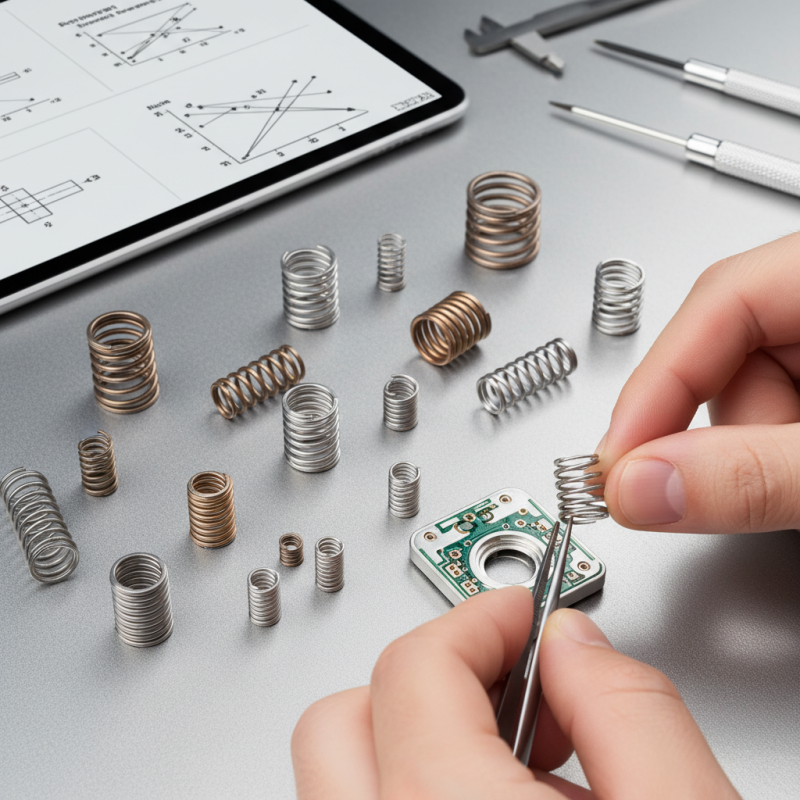

Choosing the right spring type is challenging. Many overlook the nuances of each material. Testing different combinations is often necessary. Sometimes, the spring you think is ideal may not fit your device's specific needs. Finding that perfect balance between comfort, durability, and cost can be frustrating but is essential for functionality.

Choosing the right touch button spring for your device involves several key factors. Consider the spring’s material carefully. Different materials offer varying levels of durability and elasticity. Stainless steel, for instance, provides good resistance to corrosion, while copper alloys are known for impressive conductivity. Evaluate the environment your device will face. Extreme temperatures or moisture can affect performance.

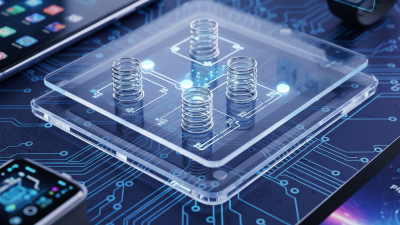

Next, think about the spring's size and shape. The dimensions must fit precisely within your device. An ill-fitting spring can lead to operational issues. Moreover, the spring's force rating is critical. If it's too soft, your button may feel unresponsive. Conversely, a spring that is too firm can hinder usability.

Don’t overlook the importance of travel distance. This measurement affects the ease of pressing the button. Short travel can lead to quick responses but might feel less satisfying. On the other hand, longer travel distances could enhance user experience but may slow down interaction. Testing different combinations is often necessary. It's challenging to find a perfect match right away. Fine-tuning may take time, but it leads to better functionality.

| Feature | Description | Importance Level | Recommendation |

|---|---|---|---|

| Spring Material | Common materials include stainless steel, brass, and plastic. | High | Choose based on durability and environmental resistance. |

| Spring Force | Measured in grams, it indicates how much force is needed to actuate the button. | High | Select based on user experience and application needs. |

| Size and Dimensions | Dimensions affect fit and design compatibility. | Medium | Ensure it fits within your device specifications. |

| Lifecycle | Number of actuations the spring can handle before failure. | High | Opt for a spring with a high lifecycle for longevity. |

| Plating and Coating | Surface finishes can improve aesthetics and reduce corrosion. | Medium | Select a finish that complements the device design. |

Choosing the right touch button spring requires careful analysis of load ratings and force requirements. Understanding these factors is crucial for optimal functionality. Load ratings indicate how much force a button can withstand. Too much force may cause failure. Insufficient rating leads to unresponsive buttons.

Consider these tips during your selection process. Assess the weight your button will experience. Use this weight to determine the necessary load ratings for reliability. Evaluate the feedback you want. A firmer press provides tactile feedback, while a lighter touch offers ease of use.

Reflect on the balance between soft and hard springs. A too-soft spring may feel flimsy. Conversely, a hard spring could lead to user frustration. Experiment with different options. Test various load ratings to find your ideal configuration. Make adjustments based on user experience. Each device may demand a unique solution.

When it comes to touch buttons, spring dimensions play a crucial role. The most critical measurements are the wire diameter, coil diameter, and overall length. For example, a thinner wire diameter can lead to a softer feel. According to a report by the Engineering Standards Association, springs with a wire diameter less than 0.8 mm show a 30% increase in compressibility. This can impact user experience significantly.

However, a trade-off exists. While softer springs improve tactile feedback, they may reduce durability. Testing reveals that springs with a larger coil diameter can endure up to 10% more compression cycles than their smaller counterparts. This is vital for devices subjected to frequent use. The right choice hinges on balancing response time with long-term durability. Choosing an inappropriate size may lead to early failure or user dissatisfaction.

Careful evaluation is essential. Underestimating the impact of spring dimensions can result in malfunctioning buttons. Reports indicate that around 15% of device returns are due to touch response issues linked to spring failure. Designers must strive to find the best fit for their specific applications. This leaves room for reflection on past design choices and room for improvement.

When selecting touch button springs, understanding industry standards is vital. Testing methods vary widely, yet they all aim for reliability. Springs are often assessed for compression, tensile strength, and fatigue. These factors ensure longevity in busy devices.

Tips for a successful selection include consulting detailed specifications. Analyze the spring's load capacity. This capacity directly influences device performance. Also, consider environmental factors like temperature or humidity. These can affect spring material and function.

Another point is the need for quality assurance. Poor quality springs can lead to device malfunctions. If you notice inconsistencies in feedback during testing, reconsider your choices. Evaluate different materials and designs. This trial-and-error process can seem tedious but is essential for optimal functioning.