Leave Your Message

Choosing the right tape reel packaging is crucial for businesses in electronic manufacturing and supply chain management. According to a recent report by Smith & Associates, over 75% of manufacturers cite inefficiencies in packaging as a major hurdle. This highlights the importance of selecting appropriate tape reel packaging for optimal performance and cost-effectiveness.

Expert John Porter, a leading figure in the packaging industry, emphasizes, “Quality tape reel packaging can significantly reduce waste and improve supply chain efficiency.” Manufacturers often overlook the specifications of tape reel packaging, leading to challenges such as damage during transport. Selecting the wrong material or size may result in product loss or increased costs.

Moreover, the diversity in components means different needs. It can be overwhelming to determine the perfect fit. Packaging should not only protect products but also make handling and transportation simpler. Balancing protection and accessibility is essential. A thoughtful approach toward tape reel packaging can minimize these issues while enhancing overall productivity.

When selecting tape reel packaging, understanding the materials is crucial.

Polypropylene and polyester are common choices.

They offer durability and resistance to moisture. Market data shows that polypropylene has a 45% market share due to its balance of cost and performance.

Polyester, with its strong tensile strength, is favored in demanding applications.

However, choosing the right material is not always straightforward.

One must consider the specific needs of the application. Some believe that thicker materials ensure better protection.

Yet, this is not always true. A thinner, high-quality material can sometimes outperform a thicker one.

Research indicates that 30% of manufacturers face challenges in finding the optimal packaging.

Many underestimate the importance of testing materials before bulk purchasing.

Sustainability is another factor. Eco-friendly options are on the rise, but they may cost more.

A report highlights that 20% of companies prioritize recyclable materials.

However, they often find these solutions less effective. Businesses must balance environmental impact with performance needs.

The decision-making process can be complex and requires careful consideration.

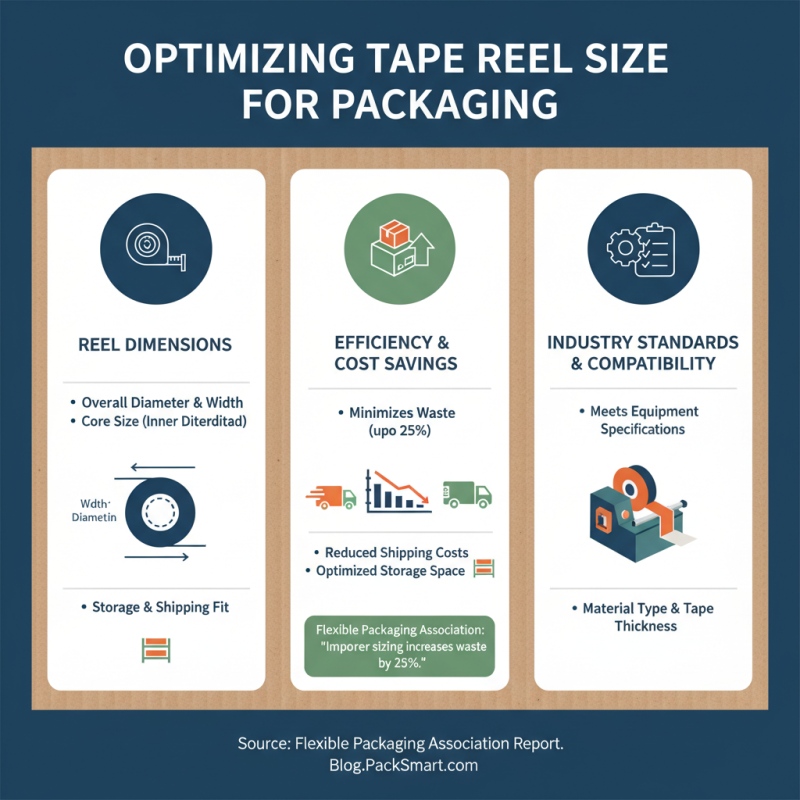

When evaluating the size and dimensions of tape reels for your packaging needs, several factors come into play. First, consider the overall dimensions of the reel itself. Industry standards typically suggest that tape reels should fit snugly within designated storage spaces. Misjudgments in size can lead to increased shipping costs or inefficiency in storage. According to a report by the Flexible Packaging Association, improper tape reel sizing can increase waste by 25%.

Choosing the right diameter can significantly impact usability. A larger diameter might allow for more tape, but it could also be cumbersome to handle. Small tape reels can be easier for manual processes, reducing the strain on workers. Standard reel widths often range from 10mm to 100mm. Think through the application!

Tips: Always measure your storage area before purchasing. Calculate the number of reels you will need. Sometimes, smaller orders can lead to better fit and less waste. Don’t just rely on general recommendations; analyze your specific requirements. Adjusting dimensions for custom orders might be the way to go. Testing various sizes in real scenarios can reveal unexpected fit issues. Remember, a rushed decision can lead to future complications.

Choosing the right tape reel packaging involves assessing the protection and durability features that suit your specific needs. A well-designed package prevents damage during storage and transport. Consider materials that can withstand different environmental conditions.

Look for packaging options made from sturdy materials. Corrugated cardboard or hard plastic often provides good protection. Evaluate if the packaging is resistant to moisture or abrasions. This choice can impact the lifespan of the contents.

Tips: Always check the weight capacity of the packaging. Not all options can hold heavy reels. Conduct a test run with limited quantities. This helps assess real-world performance.

Another factor is the closure method. Some packages may use adhesive seals. Others might rely on clips or snap closures. Each has advantages, but not every method is foolproof. Reflect on how easy it is to access the reels as well.

Consider the overall design. Ergonomics plays a role in handling. If the package is difficult to open, it can lead to frustration. Think about the intended use. Packaging that works for storage might be different from what you need for shipping.

When budgeting for tape reel packaging, clarity is key. Consider the materials used. High-quality, durable materials often cost more upfront but can save money in the long run. Think about potential waste. Low-quality packaging can lead to damaged products. This, in turn, increases replacement costs.

Explore various providers to compare prices. Some might offer bulk discounts, while others may provide package deals. Don’t just go for the cheapest option. Scrutinize additional services, such as support and customization. Each feature can impact your budget. Will you need custom sizes or designs?

Analyze your requirements carefully. The wrong choice can lead to overspending or compromised quality. Seek advice from experts if needed. They may recommend solutions that fit your budget better. Reflect on prior packaging decisions. What worked and what didn’t? This process can lead to better choices in the future.

When choosing tape reel packaging, it's essential to understand industry standards. Compliance with these standards ensures quality and safety. Different industries have different requirements. For example, electronics packaging might focus on static control, while food packaging must meet health regulations.

Tips: Always research specific compliance standards related to your industry. Consider regulations like the FDA for food or IPC for electronics. These guidelines affect material choices and labeling.

Moreover, not all packaging solutions will meet these standards perfectly. Some may lack proper certifications. This could lead to costly recalls or damage to your reputation. Regular audits of your suppliers can mitigate these risks.

Tips: Maintain open communication with your suppliers about compliance. Request documentation to verify their claims. It’s vital to ask questions and seek clarity on any uncertainties about your packaging materials.