Leave Your Message

In today's rapidly evolving manufacturing landscape, selecting the appropriate Carrier Tape Packaging Machine has become crucial for businesses aiming to enhance operational efficiency and reduce waste. With the global market for packaging machinery projected to surpass $50 billion by 2026, the importance of investing in state-of-the-art technology cannot be overstated. A recent industry report indicates that manufacturers who optimize their packaging processes can see a return on investment (ROI) of up to 30% within the first year of implementation.

Carrier tape packaging serves as a vital component in the electronics sector, specifically for protecting and transporting sensitive components such as semiconductors and microchips. According to a study by the Institute of Packaging Professionals, companies that utilize advanced carrier tape solutions experience a significant decrease in product damage during transportation, with reported damage rates dropping by as much as 20%. Furthermore, the integration of automated Carrier Tape Packaging Machines has been linked to improvements in productivity by up to 25%, highlighting their importance in maintaining a competitive edge in a market driven by efficiency and sustainability.

As businesses strive to meet the increasing demands for precision and reliability in packaging, the choice of an appropriate Carrier Tape Packaging Machine can significantly influence overall performance and profitability. Making an informed decision about the correct machinery not only streamlines operations but also ensures compliance with industry standards, ultimately contributing to the long-term success of the business.

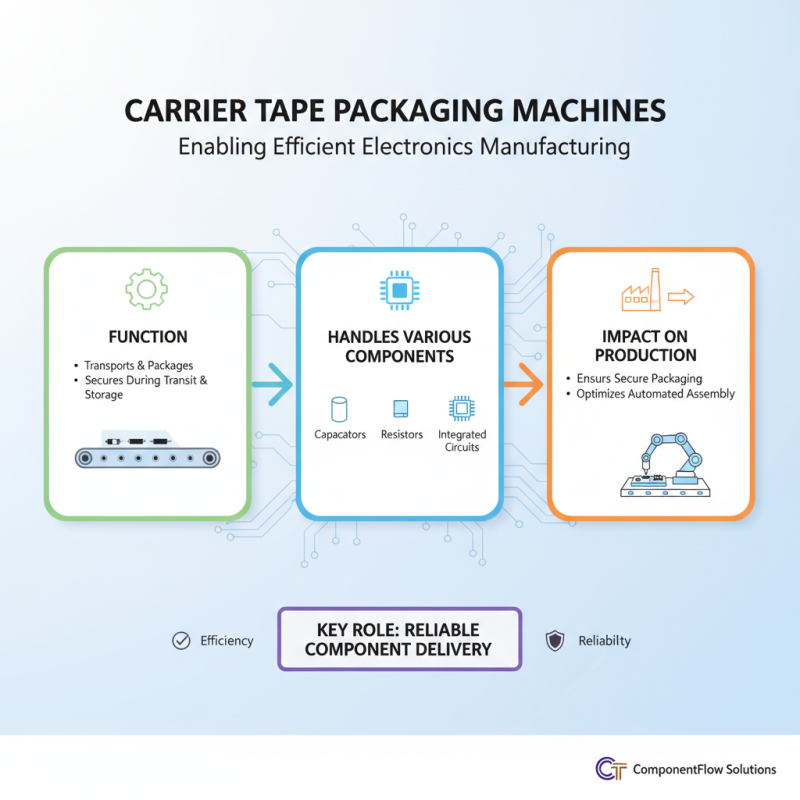

Carrier tape packaging machines play a crucial role in the electronics manufacturing industry by providing a reliable method for transporting and packaging components. These machines are designed to handle various types of components, such as capacitors, resistors, and integrated circuits, ensuring that they are securely housed during transit and storage. The correct selection of a carrier tape machine directly affects the efficiency of production processes, as it impacts how well components are packaged for automated assembly systems.

Understanding the importance of carrier tape packaging machines goes beyond their operational capabilities; it also encompasses the optimization of supply chain management. A well-chosen machine can streamline production workflows, reduce the risk of damage to sensitive components, and minimize waste through precise and standardized packaging. Additionally, investing in advanced carrier tape technology can enhance productivity and ultimately contribute to a company’s bottom line by improving inventory management and reducing lead times. In an industry where precision and efficiency are paramount, the right machine can make all the difference in maintaining competitive advantage.

When selecting a carrier tape packaging machine, several factors must be meticulously evaluated to ensure the equipment aligns with your business's specific needs. First and foremost, the machine's compatibility with the components you are packaging is crucial. Different components may require varying tape widths, depths, and configurations. Therefore, assessing the specifications of your products prior to making a decision can help in choosing a machine that optimally accommodates your requirements.

Another essential factor to consider is the machine's speed and efficiency. In a competitive market, the ability to package products quickly without compromising quality can significantly influence your operational success. Look for machines that offer adjustable speeds and high throughput capabilities. Additionally, consider the ease of operation and maintenance. A user-friendly interface can reduce training time for staff, while simple maintenance procedures can enhance machine longevity and reduce downtime. Balancing these factors will ultimately contribute to a more streamlined packaging process, driving greater efficiency for your business.

| Factor | Description | Importance Rating (1-5) | Potential Impact on Business |

|---|---|---|---|

| Machine Speed | The rate at which the machine can package items per minute. | 5 | Directly affects production efficiency and delivery times. |

| Size Compatibility | Ability to accommodate various sizes of electronic components. | 4 | Ensures versatility in operations and reduces downtime. |

| Ease of Operation | User-friendliness of the machine interface and controls. | 4 | Reduces training time and increases workforce productivity. |

| Maintenance Requirements | Frequency and complexity of machine upkeep. | 5 | Minimizes unexpected costs and machine downtime. |

| Cost of Ownership | Total costs, including purchase price, setup, and operation. | 5 | Impact on ROI and long-term financial planning. |

| Technology Integration | Ability to integrate with existing production systems and software. | 4 | Enhances workflow efficiency and data management. |

The quality of carrier tape packaging is paramount in ensuring the integrity of products, particularly in the electronics and manufacturing sectors, where delicate components are common. A well-constructed carrier tape serves not only as a protective measure but also as a means of organization and efficiency during transport and assembly.

If the carrier tape is flimsy or improperly designed, it could lead to misalignments or even damage to the components it holds, resulting in increased waste and production costs.

Moreover, the precision of the carrier tape plays a crucial role in the overall reliability of the finished product. For instance, variations in the spacing or dimension of the tape can affect how components are fed into automated machinery, heightening the risk of jams or errors during the assembly process. In a competitive market, ensuring that product integrity is maintained through quality carrier tape not only boosts operational efficiency but also enhances customer trust. Thus, investing in high-quality carrier tape packaging machines becomes an integral part of a business's strategy to uphold product standards and drive success.

Investing in the right carrier tape packaging machine is crucial for businesses looking to optimize their production efficiency and cost-effectiveness. When analyzing the costs associated with packaging equipment, it’s essential to consider not just the initial purchase price, but also the long-term benefits it can provide. A well-chosen machine can minimize downtime, reduce manual labor, and improve the accuracy of packaging, leading to significant savings in labor costs and material waste over time.

Tips for evaluating your options include assessing the machine's capability to handle various components and the flexibility it offers for future production needs. Look for machines that feature user-friendly interfaces and automation features, which can streamline operations and reduce the learning curve for staff. Additionally, consider the energy efficiency of the equipment; a machine that consumes less power can lower operational costs and contribute to a greener business model.

Another critical aspect to consider is the machine's maintenance requirements. A machine that is easy to maintain and repair can save both time and money. Be sure to investigate the warranty and support services offered by manufacturers, as reliable support can prevent costly downtimes in production. Allocating funds for quality equipment upfront can lead to a return on investment that far outweighs the initial expenditure, enhancing your overall profitability.

The carrier tape packaging industry is witnessing rapid advancements, driven by innovations that address increasing demands for efficiency and sustainability. According to a recent report by the Markets and Markets Research, the global market for carrier tape machinery is projected to reach USD 2.1 billion by 2025, growing at a CAGR of 5.4% from 2020. This growth is largely influenced by the rising need for automated solutions in electronic component packaging, as manufacturers seek to minimize manual handling and enhance throughput.

One of the future trends shaping this sector is the integration of smart technology, such as IoT (Internet of Things) connectivity and AI-driven analytics, into carrier tape packaging machines. These advancements allow for real-time monitoring and predictive maintenance, which can significantly reduce downtime. A study published by Technavio estimates that the adoption of smart machinery could lead to a 20% increase in operational efficiency. As businesses aim to navigate the complexities of supply chain management and fluctuating market demands, these innovations in carrier tape technology will be crucial for maintaining a competitive edge while also aligning with sustainability goals.