Leave Your Message

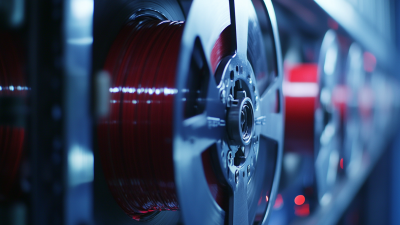

In today's fast-paced manufacturing environment, efficiency is paramount, and one crucial component that contributes to this efficiency is the Carrier Tape Reel. According to a recent report by Smithers Pira, the global market for electronic packaging is expected to reach $35 billion by 2025, highlighting the growing importance of efficient component handling systems. Proper use of Carrier Tape Reels not only streamlines the assembly process but also minimizes component damage and reduces labor costs. The integration of automated pick-and-place machinery has further underscored the significance of standardized packaging like Carrier Tape Reels, which facilitate precise and rapid component delivery. As manufacturers strive to enhance productivity and maintain quality, understanding the key reasons why Carrier Tape Reels are essential for operational efficiency becomes increasingly vital. In this article, we will delve into seven key reasons that showcase the indispensable role of Carrier Tape Reels in the manufacturing landscape.

In today's fast-paced manufacturing environment, the role of carrier tape reels is crucial in optimizing efficiency and streamlining production processes. These reels act as a protective and organized housing for electronic components, allowing for automated handling, feeding, and placement. By minimizing manual intervention and reducing the risk of damage, carrier tape reels help manufacturers enhance their throughput and reduce waste.

To maximize the benefits of carrier tape reels, consider implementing a few key strategies. First, ensure that your carrier tape is compatible with your specific components along with the feeding machinery. This compatibility will minimize jams and improve feed accuracy. Additionally, maintaining an organized inventory of carrier tape reels can greatly enhance workflow. Use labeled storage solutions to quickly identify and access the required tapes, facilitating smoother transitions between production runs.

Another tip is to regularly review the performance of your carrier tape systems. Monitoring metrics such as component placement accuracy and downtime caused by feeder issues can provide valuable insights into areas for improvement. Investing in high-quality carrier tapes and periodically updating your systems will ensure that your manufacturing operation remains efficient and competitive in the ever-evolving market.

In the fast-paced world of manufacturing, component protection is paramount to ensuring product quality and efficiency.

Carrier tape reels play a critical role in safeguarding electronic components during transportation and storage. According to a report by IPC, a leading trade association for the electronics industry, improper handling and environmental factors can lead to up to 30% of defects in assembled electronic components. Using carrier tape reels significantly reduces these risks by providing a controlled environment that minimizes movement and exposure to contaminants.

Carrier tape reels play a critical role in safeguarding electronic components during transportation and storage. According to a report by IPC, a leading trade association for the electronics industry, improper handling and environmental factors can lead to up to 30% of defects in assembled electronic components. Using carrier tape reels significantly reduces these risks by providing a controlled environment that minimizes movement and exposure to contaminants.

Furthermore, the design of carrier tape reels facilitates ease of use during assembly, which can lead to increased productivity. Research from the Electronics Industry Association (EIA) indicates that utilizing effective packaging solutions, such as carrier tape reels, can enhance assembly line efficiency by up to 15%. By ensuring that components are securely held and easily accessible, manufacturers can streamline their processes, reduce assembly time, and ultimately cut costs. The benefits of adopting carrier tape reels extend beyond mere protection; they are a key component in optimizing manufacturing operations and delivering high-quality electronic products.

In the fast-paced world of manufacturing, enhancing production speed is critical to staying competitive. One of the most effective tools for achieving this is the carrier tape reel. By organizing components securely and allowing for automated feeding, carrier tape reels streamline the assembly process, significantly reducing downtime and labor costs. Each component is held in place, enabling quick and efficient transfer from one station to another, minimizing the risk of errors that often occur during manual handling.

Moreover, the design of carrier tape reels allows for seamless integration with assembly line machinery. Automated solutions can reliably pick and place components, resulting in higher throughput rates. This automation not only accelerates production speed but also supports consistent quality, as machines are less prone to the variations in handling that can affect human operators. Consequently, investing in carrier tape reels directly correlates with improved operational efficiency, enabling manufacturers to meet demand without compromising on quality or speed.

| Dimension | Details |

|---|---|

| Increased Productivity | Carrier tape reels streamline the assembly process, allowing for faster pick-and-place operations. |

| Reduced Setup Time | Standardized reel sizes minimize the time required to set up production runs. |

| Improved Inventory Management | Easier tracking and replenishment of component inventory using carrier tape systems. |

| Enhanced Component Protection | Carrier tapes provide secure containment that protects components from damage. |

| Versatility | Accommodates a wide variety of electronic components for diverse manufacturing needs. |

| Reduced Labor Costs | Automated setups decrease the reliance on manual labor, reducing overall workforce costs. |

| Improved Quality Control | Systems integrating carrier tape help in maintaining accurate counts and reduce errors. |

In the fast-paced world of manufacturing, every detail counts, and the choice of packaging for components can significantly impact operational efficiency.

Carrier tape reels play a crucial role in reducing waste and minimizing costs.

According to a recent report by the Institute for Manufacturing, up to 30% of production costs can be attributed to material waste in the assembly process.

By utilizing carrier tape, manufacturers can streamline the feeding of components, ensuring precise placement and significantly reducing the likelihood of misplacements or damages.

This not only translates into lower waste rates but also maximizes throughput, helping companies maintain their competitive edge.

Moreover, the economic advantages extend beyond waste reduction. Implementing carrier tape reels can lead to a decrease in labor costs, as automated systems can handle the precise dispensing of components.

The Electronics Industry Association reports that companies utilizing automated assembly systems, which often incorporate carrier tape, see an average productivity increase of 15-20%.

This enhanced efficiency allows for faster turnaround times, ultimately leading to improved customer satisfaction and a stronger bottom line.

As manufacturing processes evolve, incorporating innovative solutions like carrier tape reels becomes essential for companies looking to maintain cost-effectiveness and efficiency in an increasingly competitive market.

In today's fast-paced manufacturing environment, ensuring product reliability is paramount, and one often overlooked aspect is the role of carrier tape reels. These specialized packaging solutions not only streamline the transportation of electronic components but also significantly enhance quality control processes. By providing a standardized method for storing and delivering components, carrier tape reels reduce the risk of damage during handling and transit, ensuring that products remain intact until they reach the assembly line.

Moreover, the design of carrier tape reels facilitates better organization and traceability of components. This organized system allows manufacturers to maintain strict quality control measures, helping to identify any defects or issues early in the production process. As a result, maintaining a consistent flow of high-quality components becomes more manageable, resulting in fewer disruptions and a more reliable end product. In an industry where precision and accountability are crucial, the impact of carrier tape reels on product reliability cannot be overstated.