Leave Your Message

In the evolving landscape of technology, the relevance of the Touch Button Spring is undeniable. Experts like Dr. James Patterson, a leading engineer in the field, emphasize, "The Touch Button Spring is a game-changer in user interaction." This component is critical in devices that require tactile feedback, such as smartphones and appliances.

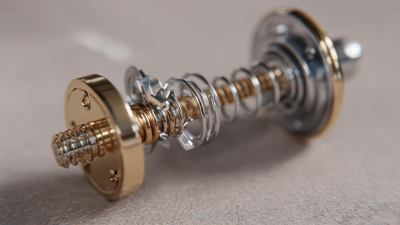

The design and functionality of the Touch Button Spring allow for precise control and responsiveness. However, challenges remain in optimizing its durability and sensitivity. Users may overlook these aspects until they impact performance. Even the most advanced designs can face issues under heavy usage or environmental stress.

As industries integrate touch technology, understanding the best features of Touch Button Springs becomes essential. The balance between innovation and reliability is often hard to achieve. Companies must reflect on the user experience to enhance their designs. In doing so, they can better serve the demands of an increasingly intuitive world.

Touch button springs play a crucial role in various electronic devices, from remote controls to medical equipment. They provide tactile feedback, enabling users to interact with devices effortlessly. Data from industry reports indicates that the global touch button spring market is projected to grow by 5.3% annually, highlighting their increasing demand.

One key feature of touch button springs is their versatility. They can be designed for different actuation forces, ensuring user comfort across applications. For instance, springs with a lower actuation force are more suitable for portable devices. However, while many manufacturers offer diverse spring options, some fail to consider the longevity of the materials used. This oversight can lead to premature failure and customer dissatisfaction.

In addition, the materials chosen for touch button springs significantly impact their performance. Stainless steel and nickel alloys are commonly used due to their resilience. But sourcing sustainable materials remains a challenge. Not all industries prioritize eco-friendliness, resulting in a gap between performance and environmental responsibility. It’s essential to reflect on the balance between functionality and sustainability in future designs.

Touch button springs are essential components in many electronic devices. They offer a unique combination of features that enhance user interaction. These springs provide tactile feedback, which can significantly improve the user experience. When pressed, they create a satisfying response, letting users know their input was registered.

One key feature of touch button springs is their durability. Made from high-quality materials, they withstand many activations. This longevity is vital for devices that see frequent use. Additionally, their compact design allows for easy integration into various applications. They are used in smartphones, remote controls, and appliances. However, not all springs perform well under pressure. It's essential to consider the specific requirements of each application. Smaller devices may require springs with different characteristics than larger ones.

Another important aspect is customization. Touch button springs can be designed to meet specific needs. You might find variations in size, stiffness, and actuation force. A thoughtful design process is crucial to ensure optimal performance. Experimenting with different configurations can lead to surprising outcomes. However, achieving the right balance may take time and iteration. Learning from each design trial can lead to improved results in the long run.

Touch button springs play a crucial role in various electronic devices. Their functionality relies heavily on the materials used in their construction. Common materials include stainless steel, copper alloys, and plastic composites. Each of these materials has unique properties that impact the spring's performance and durability.

Stainless steel is often favored for its resistance to corrosion. It provides a good balance of strength and flexibility. However, it might not always be the best choice for lightweight applications. Copper alloys, on the other hand, offer excellent electrical conductivity. They are usually more expensive and can be prone to oxidation. This can affect long-term performance.

Plastic composites have gained popularity due to their lightweight nature. They can be molded into complex shapes, but they may not provide the same mechanical strength as metals. This raises questions about their long-term reliability under stress. Choosing the right material for touch button springs is often a delicate balance. Each option has strengths and weaknesses that must be considered carefully.

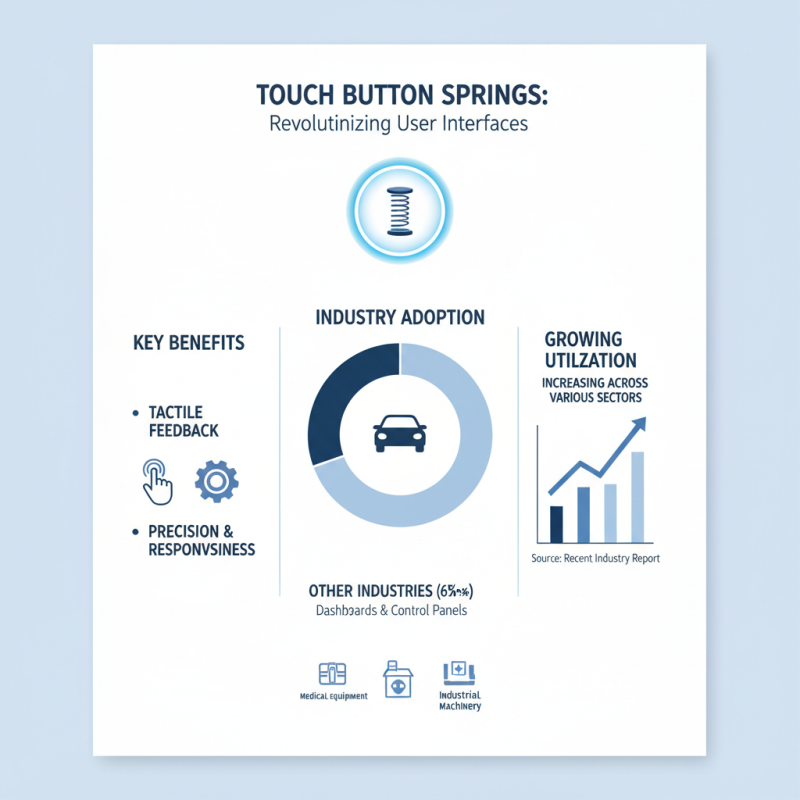

Touch button springs are increasingly utilized across various industries, revolutionizing user interfaces. Their tactile feedback is crucial in applications requiring precision. According to a recent industry report, the automotive sector accounts for over 35% of touch button spring usage. This includes dashboards and control panels, where user interaction must be both intuitive and responsive.

In consumer electronics, touch button springs are essential. They enhance devices like smartphones and appliances. It’s noted that about 40% of users prefer devices with tactile feedback. This feedback creates a connection between the user and the device, making operations feel more secure. However, not all designs are flawless. Some users report inconsistent feedback, which can lead to frustration.

The healthcare industry also benefits from touch button springs. Devices such as medical equipment require reliable user interfaces. Reports suggest that accurate touch applications improve patient outcomes. Yet, the challenge remains in producing springs that can withstand various environmental factors. Durability and reliability must be constantly assessed.

Touch button springs play a crucial role in various electronic devices. They ensure functionality and user satisfaction. However, proper maintenance is often overlooked. Without adequate care, these springs can wear out quickly, leading to malfunction. Regular inspections are essential. Check for corrosion or physical damage regularly.

Cleaning the springs, too, can improve their longevity. A simple wipe with a soft cloth works wonders. Avoid harsh chemicals; they can cause damage. It's important to ensure the area around the buttons stays clean as well. Dust and debris can hinder performance.

Users often forget to observe the tactile feedback of the buttons. If you notice less resistance, it's time to rethink your maintenance routines. Replacement can be necessary, but prevention is key. Keep a close eye on usage patterns and stress factors. Over time, adapting best practices becomes crucial. Proper handling can extend the lifespan of touch button springs significantly.

| Feature | Description | Applications | Best Practices |

|---|---|---|---|

| Material Composition | Typically made from stainless steel or high tensile strength alloys for durability. | Consumer electronics, automotive switches, and medical devices. | Ensure correct material type is used for specific applications to enhance lifespan. |

| Coil Geometry | Variety of coil designs available to cater to different load requirements. | Keypads, home appliances, and industrial machinery. | Select appropriate coil design to match operational speed and force needs. |

| Force Characteristics | Customizable force characteristics to provide desired tactile feedback. | Gaming controllers and device interfaces. | Test different force options during prototyping to enhance user experience. |

| Environmental Resistance | Ability to withstand environmental factors such as moisture and temperature changes. | Outdoor equipment and marine applications. | Use corrosion-resistant coatings and seals for added protection. |

| Dimensional Accuracy | High precision manufacturing standards to ensure consistent spring performance. | High-tech devices and precision instruments. | Implement quality control measures to maintain dimensional integrity. |