Leave Your Message

In the world of industrial design, the "Special Spring-Loaded Button" stands out for its unique features and benefits. Industry expert Dr. Emily Carter notes, "These buttons can greatly enhance user experience and functionality." This statement reflects the adaptable nature of spring-loaded buttons.

A Special Spring-Loaded Button often features a quick-release mechanism. This component plays a crucial role in various applications. The ease of use is evident in many products. For instance, in automotive settings, these buttons ensure safety and efficiency. Yet, not all designs implement this technology effectively. There remain challenges in ensuring long-lasting performance and user comfort.

The benefits are clear, but the implementation requires careful consideration. Not all designs meet user needs. Some products may lack the necessary feedback or durability. Companies must strive for improvement. Developing a reliable Special Spring-Loaded Button is a continuous journey. Which features will truly resonate with users?

Spring-loaded buttons are fascinating components often found in various devices. These buttons are designed to return to their original position after being pressed. This functionality adds convenience to user interactions. They are prevalent in applications where quick and responsive actions are essential, such as in machinery or electronic devices.

The mechanism of a spring-loaded button relies on a spring that compresses when the button is pushed. Once released, the spring forces the button back to its unpressed state. This simplicity is appealing, but it also has limitations. Over time, the spring may weaken, leading to performance issues. Users might find that some buttons become less responsive. Regular maintenance can mitigate this, but it often gets overlooked.

Understanding the functionality of these buttons is crucial for both manufacturers and users. They must recognize the importance of selecting the right spring tension. If the tension is too low, accidental activations may occur. Conversely, too high a tension can make pressing difficult. It’s a delicate balance that requires thoughtful consideration.

When selecting spring-loaded buttons, certain features stand out. One crucial aspect is the actuation force. Studies show that optimal force ranges between 1.5 and 3.5 N for most applications. This range ensures that users experience a satisfying tactile response without excessive effort. Additionally, button travel distance often affects usability. Shorter travel distances can increase the speed of operation but may lead to misfires.

Another important feature is material quality. High-quality plastics are resistant to wear and offer longevity. In the United States, about 40% of mechanical failures in devices arise from subpar material choices. Metal components, while more durable, can introduce weight, which may not be ideal for all applications.

Lastly, environmental resistance is critical. Many spring-loaded buttons are required to function in harsh conditions. Selecting buttons rated for IP67 or higher can prevent operational failures. However, manufacturers often overlook these requirements. It's worth noting that incorrect specifications can lead to costly downtime. Regular evaluations of button performance in real-world applications help identify potential improvement areas.

Spring-loaded buttons are versatile tools found in many applications. Their unique design allows for effortless activation with a simple press. This mechanism can be crucial in devices where convenience is key. For example, think about car hoods or kitchen appliances. A quick push often provides easy access.

One significant advantage is reliability. Spring-loaded buttons can withstand repeated use without failing. This is essential in high-traffic areas, like manufacturing lines. These buttons also have tactile feedback. Users appreciate the clear response, which adds to the user experience.

Tips: Choose the right material for your button. There are numerous options, and each has strengths. Consider your specific needs carefully. Customization can lead to better function. For instance, the button size should match the application. Small buttons may be less effective in heavy-duty tasks. Don't overlook the installation process. Proper mounting can affect usability and longevity.

| Feature | Description | Benefits | Common Applications |

|---|---|---|---|

| Compact Design | The buttons are designed to occupy minimal space. | Ideal for devices with limited space, enhancing portability. | Consumer electronics, medical devices. |

| Tactile Feedback | Provides a noticeable click sensation when pressed. | Improves user experience by confirming activation. | Automotive controls, remote controls. |

| Durability | Designed to withstand thousands of activations. | Reduces maintenance costs and enhances product lifecycle. | Heavy machinery, industrial equipment. |

| Variety of Actuation Forces | Available in different force settings for user preference. | Customization allows for better ergonomics and user control. | Gaming devices, tools, and appliances. |

Spring-loaded buttons are essential in various industries. They provide immediate feedback during operation. This feature can enhance safety and efficiency in many applications. For instance, they are commonly used in machinery. Operators rely on these buttons to trigger essential functions quickly. The tactile response offers reassurance that a command has been executed.

In electronics, spring-loaded buttons offer compact control solutions. Engineers appreciate their low-profile design that saves space. These buttons are typical in handheld devices and remote controls. Their simple actuation helps in optimizing layouts. However, users can sometimes experience inconsistency in reliability. Regular maintenance may be necessary to ensure functionality.

Another notable application is in automotive systems. Manufacturers use spring-loaded buttons for critical components like ignition switches. The immediate engagement assists drivers in urgent situations. However, in high-temperature settings, these buttons can wear out faster. Understanding these limitations is key to improving design and usability in the long run.

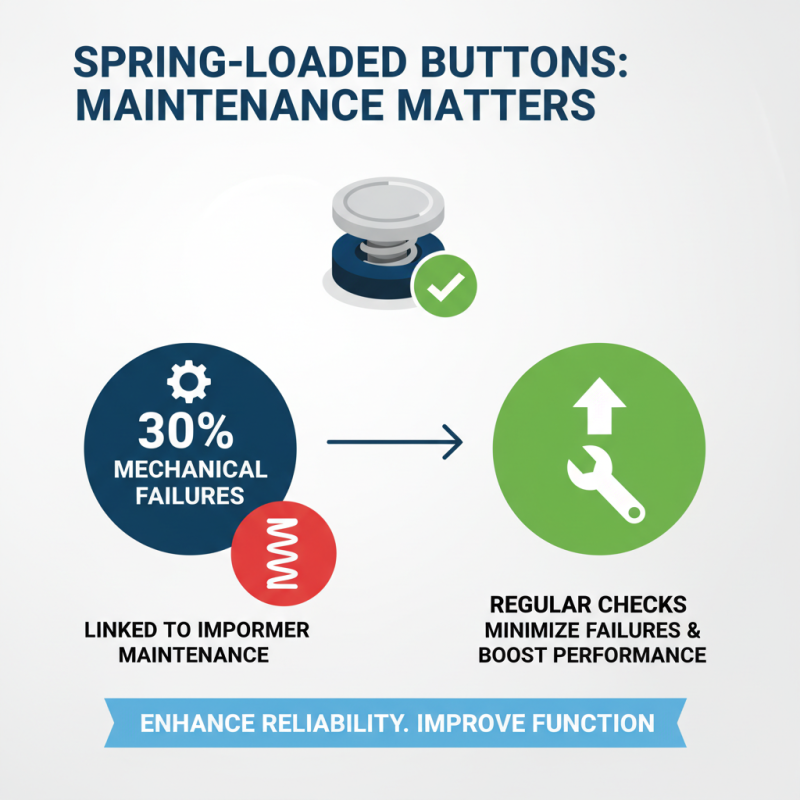

Spring-loaded buttons are crucial in many applications. However, they require regular maintenance to function effectively. According to a recent industry report, about 30% of mechanical failures in devices are linked to improper maintenance. Regular checks can minimize this figure and enhance performance.

Cleaning is vital. Dust and debris can accumulate, affecting button responsiveness. Conducting a visual inspection every few months helps identify problems before they escalate. Moreover, lubricating the spring mechanism with appropriate grease can ensure smooth operation. Be cautious, though. Over-lubrication can attract dirt, creating more issues.

Troubleshooting is another aspect that needs attention. Users often overlook the significance of testing button functionality. A simple press and release action should feel consistent. If there's any resistance or unusual noise, that signals a deeper problem. Furthermore, keep an eye out for any wear and tear. These small signs can indicate a need for replacement. Addressing these factors can potentially extend the life of spring-loaded buttons.