Leave Your Message

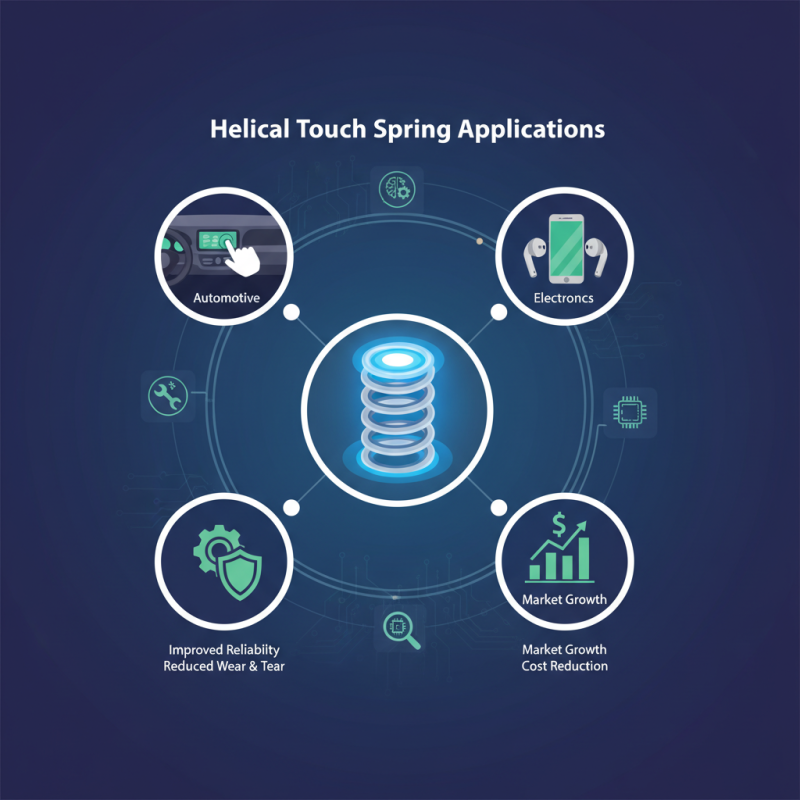

Helical Touch Springs are revolutionizing various industries, from automotive to electronics. According to a report by MarketsandMarkets, the global spring market is projected to reach $3.9 billion by 2026. A key component driving this growth is the demand for innovative spring designs. These helical springs offer high performance in limited spaces, making them ideal for compact devices.

The benefits of Helical Touch Springs extend beyond just size. Their unique design allows for better energy absorption and improved reliability. A study by the International Journal of Mechanical Engineering highlighted that these springs reduce wear and tear, potentially lowering maintenance costs. Yet, there's a learning curve in implementing this technology effectively. Companies must stay aware of manufacturing imperfections, which could impact overall performance.

As we explore applications and benefits of Helical Touch Springs in 2026, we must reflect on the need for continuous innovation. The industry is evolving, but challenges remain. Understanding the real-world implications of these advancements is crucial for future success.

Helical touch springs are a unique component used in various applications. Their design features make them versatile and efficient for many uses. These springs are spring coils that allow for controlled compression and extension. The helical shape provides a larger contact area. This design can improve the overall mechanical efficiency of products.

Tips: When choosing helical touch springs, consider the application requirements. Calculate the spring constants necessary for your product. This ensures optimal performance.

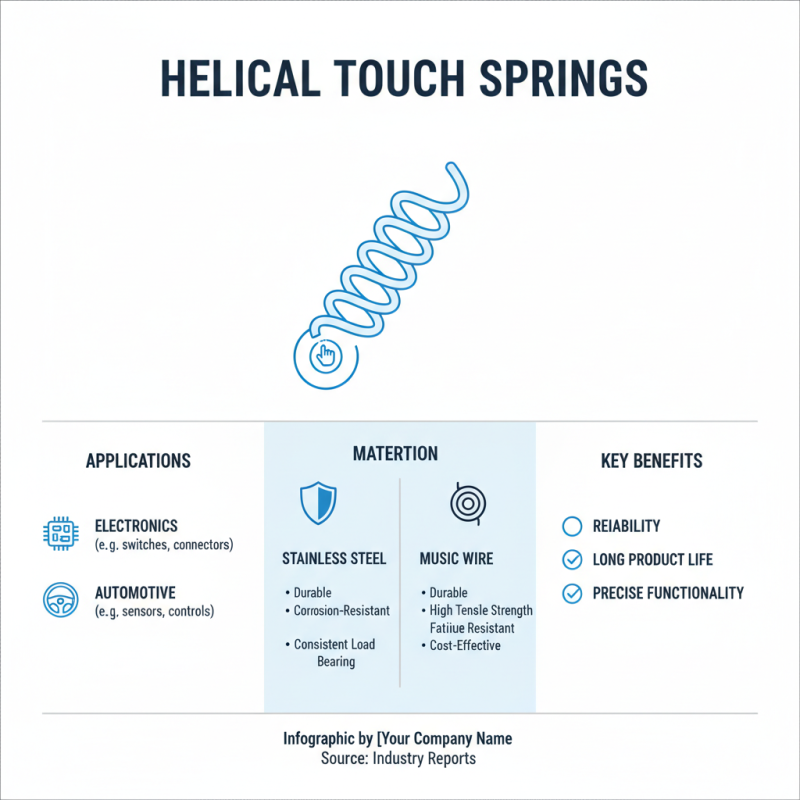

The design often incorporates specific material selections. The materials affect durability and resistance to wear. Improper material can lead to premature failure. Testing is crucial to ensure that the springs meet your desired specifications.

Tips: Always prioritize quality in selection. It’s better to invest in reliable components. Regular inspections can prevent larger issues down the line. Consider the environment where the springs will operate, as it impacts their lifespan.

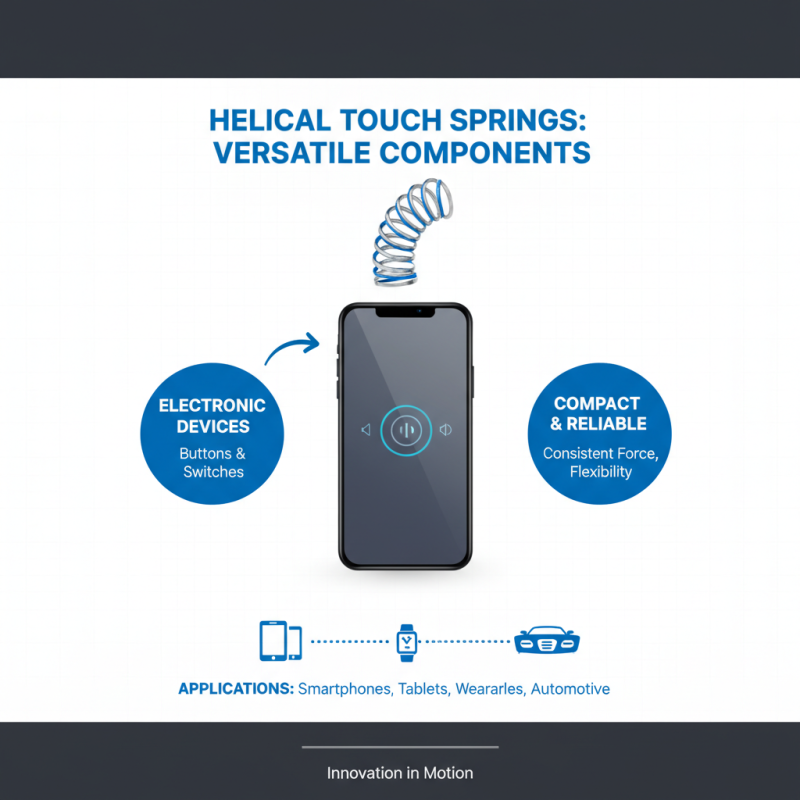

Helical touch springs are versatile components in various industries. They provide consistent force and flexibility in applications. One key area is in electronic devices. These springs ensure smooth operation for buttons and switches. Designers often choose them for their compact size and reliable performance. In smartphones and tablets, their importance cannot be overstated.

In automotive applications, helical touch springs are crucial. They help in the functioning of controls and dashboard interfaces. These springs enhance user experience by providing tactile feedback. However, manufacturers sometimes overlook material quality. Using subpar materials can lead to failures. This oversight can cause frustration for users.

The medical field also benefits from helical touch springs. They are used in diagnostic devices and surgical instruments. Precision is vital here, and these springs help achieve that. Yet, cost pressures may push companies to compromise. This could impact the reliability of important medical equipment. Careful consideration is necessary to balance cost and performance.

Helical touch springs are increasingly favored in mechanical systems due to their versatility. These springs provide consistent pressure and reduce wear. Their design allows for efficient energy storage and release, making them ideal for a variety of applications. Recent reports estimate that utilizing helical springs can improve operational efficiency by up to 15%. This translates into not only cost savings but also enhanced performance in machinery.

The benefits of helical touch springs extend beyond mere functionality. The shape and structure allow for greater stability under load. This characteristic leads to improved reliability in high-stress environments. Nonetheless, designs can vary, and assessing the right specifications is crucial. A miscalculation can lead to ineffective performance. Moreover, while many industries rely on these springs, there's still room for innovation. Exploring new materials could enhance their durability and adaptability.

Despite the clear advantages, challenges persist. The manufacturing process must ensure precision to avoid defects. Small variations can affect performance significantly, and continual testing is essential. The industry's push for sustainability means that adapting helical springs to eco-friendly materials will be vital moving forward. Balancing functionality with environmental considerations remains a key area for improvement.

Helical touch springs are crucial components in various applications, including electronics and automotive industries. Material selection is vital. Common materials include stainless steel and music wire, chosen for their durability and fatigue resistance. According to industry reports, stainless steel can withstand loads consistently, enhancing product longevity.

Manufacturing processes for helical touch springs significantly impact their performance. Precision coiling is essential. This process ensures uniform tension and adequate stress distribution. However, not all manufacturers achieve uniformity. Variability in coiling can lead to inconsistent performance. Reports indicate a 15% failure rate in springs that do not adhere to strict manufacturing standards.

Quality control is another area that requires attention. Insufficient testing methods often result in critical issues. Techniques like fatigue testing and tensile strength evaluation are crucial yet sometimes overlooked. A staggering 30% of springs fail to meet industry standards due to inadequate quality assurance. This cannot be ignored. Addressing these shortcomings is essential for maximizing the benefits of helical touch springs.

The future of helical touch spring technology is promising. These springs provide excellent performance in various applications, particularly in automotive and consumer electronics. As technology evolves, manufacturers are exploring innovative designs. This trend could lead to increased durability and more compact sizes.

In addition, smart technology integration is becoming significant. Imagine springs that adjust tension based on user input. This could enhance user experience in devices. However, the development process may be complex. Engineers might face challenges in achieving the desired responsiveness.

Sustainability is another vital aspect. Eco-friendly materials can reduce environmental impact. While this sounds ideal, sourcing these materials can be difficult. Companies must balance performance and ecological responsibility. Helical touch springs are set to play a critical role in shaping future technology.