Leave Your Message

Stainless Steel Springs play a vital role in various industries due to their durability and resistance to corrosion. Expert Robert Harrison, a leading materials engineer, states, “Stainless Steel Springs offer reliability where other materials fail.” This highlights their importance in critical applications.

In the automotive and aerospace sectors, these springs ensure safety and performance. They withstand harsh conditions while maintaining functionality. Their resilience reduces the need for frequent replacements, saving time and costs. Yet, some organizations underestimate their long-term benefits.

Despite their advantages, not all users fully understand the various types of Stainless Steel Springs available. This lack of knowledge can lead to improper selection, affecting overall project efficiency. Users must thoroughly consider their needs when choosing the right spring for their application.

Stainless steel springs offer numerous advantages for industrial applications. These springs are known for their durability and resistance to corrosion. This makes them ideal for use in harsh environments. Factories, automotive industries, and even aerospace sectors benefit from their reliable performance. The longevity of stainless steel springs can reduce the frequency of replacements, saving both time and money.

Another significant benefit is their ability to withstand high temperatures. Many industrial processes involve significant heat, and stainless steel springs maintain their mechanical properties under such conditions. They have a unique resilience, making them suitable for demanding tasks. However, the initial cost of stainless steel can be higher than other materials. This upfront investment may require careful consideration for budget-conscious projects.

While stainless steel springs are robust, they are also heavier. This can influence the overall weight of the machinery they are part of. Engineers must analyze whether this weight could pose any problems in their specific designs. Balancing weight and performance is crucial. In some cases, lighter materials might be preferable. Despite these considerations, the advantages of stainless steel springs often outweigh the drawbacks for many industrial applications.

Stainless steel springs are known for their impressive corrosion resistance. This property is crucial in many environments. For instance, in marine applications, exposure to saltwater is inevitable. Yet, stainless steel springs can withstand these harsh conditions without deteriorating. They maintain their structural integrity over time, ensuring long-lasting performance.

Longevity is a significant advantage of stainless steel springs. Unlike other materials, they don’t rust easily. A spring exposed to moisture might corrode quickly. However, stainless steel springs can operate effectively for years, reducing the need for frequent replacements. This durability can save costs in the long run.

Despite these benefits, stainless steel springs are not perfect. In some environments, high temperatures can affect their performance. Over time, stress can also lead to fatigue. Users must consider these factors when selecting springs. Regular maintenance and inspections can help catch any potential issues early. This proactive approach ensures they function optimally throughout their lifespan.

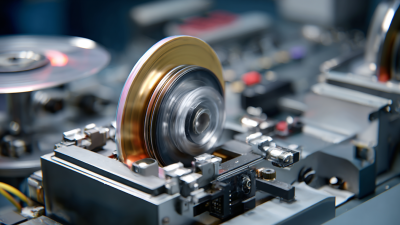

Stainless steel springs offer remarkable versatility across various industries. They are commonly used in automotive applications due to their strength and resistance to corrosion. These springs perform reliably under extreme conditions, ensuring vehicle safety. Many manufacturers opt for stainless steel because it lasts longer than other materials. This longevity reduces replacement costs over time.

In the medical field, stainless steel springs are vital components in critical devices. They provide precise force and control in equipment like surgical instruments. The biocompatibility of stainless steel makes it a safe choice for medical applications. However, the precision required can be challenging to achieve. Small errors in the manufacturing process can lead to complications.

Even in consumer products, stainless steel springs play a key role. They are found in items such as kitchen gadgets and furniture. Their ability to maintain tension over years of use is beneficial. Yet, designing products that utilize these springs effectively can be complex. Balancing cost and quality often requires careful planning and testing.

| Industry | Application | Benefits |

|---|---|---|

| Automotive | Suspension Systems | High corrosion resistance, durability under stress |

| Aerospace | Landing Gear | Lightweight, strong, high fatigue resistance |

| Medical | Surgical Instruments | Hygienic, easy to sterilize, resistance to biological agents |

| Construction | Structural Components | Longevity, resistance to environmental degradation |

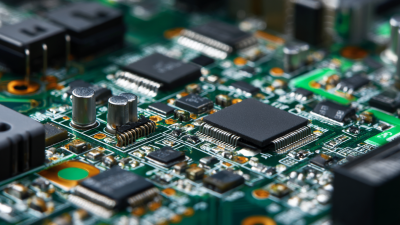

| Electronics | Clamping Mechanisms | Conductivity, stability under temperature variations |

When it comes to springs, materials matter. Stainless steel springs stand out across many applications. They provide excellent corrosion resistance. This makes them ideal for outdoor uses. In settings like construction, their durability shines. Stainless steel can handle extreme weather better than many alternatives.

Comparing stainless steel to other materials reveals a mixed bag. For instance, carbon steel is cheaper but not as durable. It rusts quickly, especially in humid conditions. Similarly, plastic springs might be lightweight, but they can’t match stainless steel's longevity. Weakness under heat is a significant drawback.

There are challenges with stainless steel too. It can be more expensive initially. This can concern budget-strapped projects. Furthermore, the manufacturing process requires precision. Any miscalculation might lead to compromised integrity. These factors push some to reconsider their options. Despite drawbacks, the long-term benefits of stainless steel springs are hard to ignore.

Stainless steel springs are becoming a favored choice in many industries. Their durability offers a long lifespan. This translates to less frequent replacements and lower maintenance costs. Unlike other materials, stainless steel is less prone to corrosion. This means fewer worries in harsh environments. Companies can save money over time by reducing material waste.

In production, the initial investment in stainless steel springs can be higher. However, the returns are often worth it. Their robustness leads to consistent performance, hence improved overall efficiency. Many manufacturers report fewer interruptions in production due to spring failures. This is a crucial point to consider for productivity. On the flip side, some might hesitate due to upfront costs. It’s essential to weigh this against long-term benefits.

Moreover, stainless steel springs contribute to sustainability. Their recyclability reduces the environmental impact. This can appeal to eco-conscious consumers. Yet, some may overlook these factors in favor of short-term savings. A careful evaluation of both costs and benefits is vital. Making informed decisions will lead to better outcomes.