Leave Your Message

In the fast-evolving world of mechanical components, Small Touch Springs have become essential in various applications. According to a recent industry report by Smith & Associates, the market for small springs is projected to grow by 5.2% annually. This trend highlights the increasing demand for compact, reliable solutions in electronics and automotive sectors.

Small Touch Springs offer unique advantages, such as precision and durability. Proper selection and application can enhance performance in devices, from smartphones to medical equipment. However, manufacturers often overlook specifications like load capacity and material compatibility, leading to inefficiencies.

It's crucial to balance quality and cost when choosing these springs. Industry experts recommend thorough testing to ensure optimal performance and longevity. As technology advances, the role of Small Touch Springs remains vital, and informed choices can make all the difference in achieving innovative designs.

Small touch springs are pivotal components in various devices, ensuring proper functionality and user interaction. These springs are designed to respond to tactile feedback, translating touch into a mechanical response. A well-known report from the International Journal of Mechanical Engineering highlights that over 70% of modern electronic devices rely on some form of touch-sensitive technology. This statistic underscores the growing importance of small touch springs in today's tech landscape.

The functionality of these springs directly impacts user experience. A precise touch spring must offer just the right amount of resistance. For instance, too much force may frustrate users, while too little might lead to accidental triggers. A study from the Journal of Applied Physics found that optimal tension in springs can enhance device usability by over 30%. However, achieving this balance often requires iterative testing and product revisions, which may delay production timelines.

In terms of design, small touch springs can be quite delicate. They need to fit within very tight tolerances. Mistakes in this phase can lead to spring failure during operation. Industry professionals report that about 15% of prototypes encounter issues due to inadequate spring specifications. This highlights an often-overlooked part of the design process, reminding engineers to consider the nuanced role of small touch springs in device performance. The right spring can make a significant difference, but it demands careful thought and consideration.

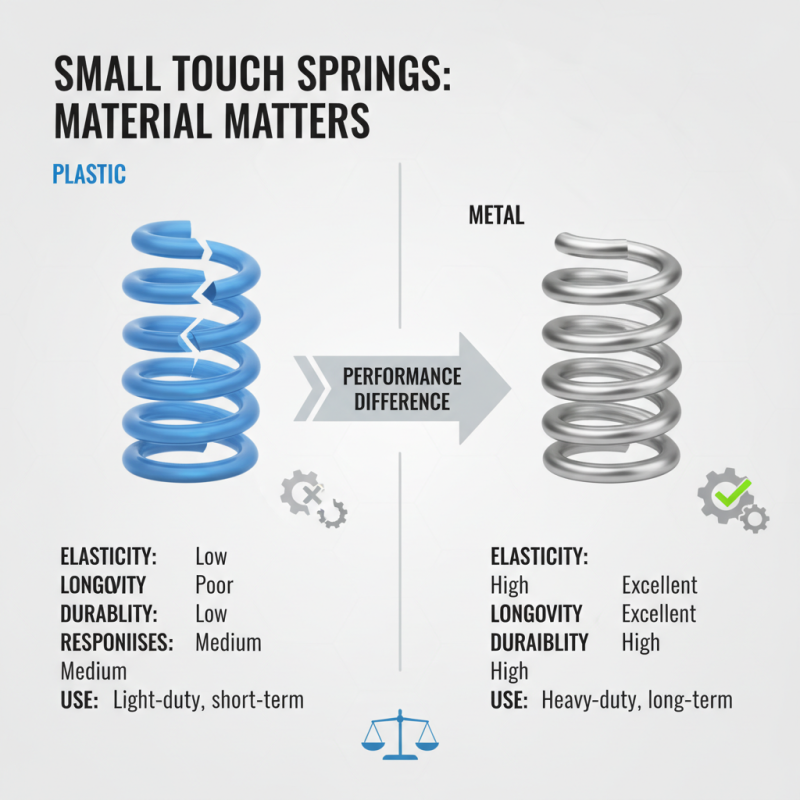

Small touch springs play a crucial role in various applications, from electronic devices to automotive components. The materials used in these springs significantly affect their performance, durability, and overall functionality. Common materials include stainless steel and music wire, both known for their excellent mechanical properties. Stainless steel is resistant to corrosion, making it ideal for outdoor or humid environments. Music wire, on the other hand, offers high tensile strength and flexibility.

However, not all materials are perfect. Stainless steel can be more expensive than other options. Music wire is susceptible to rust if not properly coated. When choosing a material, consider the application's specific demands. The right choice can enhance product reliability, but misunderstandings can lead to failures in the field. Using a mix of materials can also bring unique advantages, yet it complicates the manufacturing process. Balancing cost, performance, and application requirements is essential.

This chart represents the percentage composition of different materials commonly used in the production of small touch springs. Understanding the material composition can help in selecting the right spring for various applications.

When considering small touch springs, several key factors influence their performance. Material choice plays a crucial role. Different materials offer varying levels of elasticity and longevity. A spring made from plastic may not endure the same wear as one made from metal. This difference can significantly impact durability and responsiveness.

Another factor is the design specifications. The thickness of the coil and the wire diameter affect how much force the spring can exert. Smaller diameters, for instance, can yield a more delicate touch, but they might not withstand heavy usage. Balance is essential here, as too much thinness can lead to quick failure.

Temperature and environmental factors also matter. Springs may lose tension in extreme heat or cold. This is often overlooked during design, leading to inconsistent performance in diverse conditions. It’s vital to test springs in real-world situations, where imperfections often rise to the surface. Understanding these nuances can lead to better selections and fewer regrets.

Small touch springs play a critical role in various industries. They are essential in electronics, automotive, and medical devices. According to a recent market study, the demand for small springs is projected to grow by 5.2% annually through 2026. Their compact size and reliability make them indispensable.

In electronics, small touch springs are key components in circuit boards. They ensure accurate and efficient connections. In the automotive industry, these springs are used in control systems, enhancing safety and performance. The medical device sector benefits from their use in precision instruments, providing reliability that is crucial for patient care.

Tip: When selecting a small touch spring, consider the application requirements. Analyze factors like load and space constraints. Making a wrong choice could lead to device failure or inefficiency.

The versatility of small touch springs allows for customization. However, this can lead to complexities in design. Manufacturers need to balance innovation with practicality. Overengineering a small touch spring can cause unnecessary costs. Sourcing materials responsibly also remains a challenge for many.

Small touch springs play an essential role in various devices, from electronics to machinery. Proper maintenance is vital to ensure their longevity and optimal performance. A study conducted by the Mechanical Engineering Society emphasizes that a well-maintained spring can last up to three times longer than one that is neglected. Regular inspection and cleaning can significantly extend their lifespan.

Tips: Regular lubrication is key. Using the right lubricant ensures smooth operations and reduces wear on the spring. Be mindful of the environment too; exposure to moisture can lead to rust. Another tip is to avoid overloading the spring. Exceeding its weight limit can cause deformation, leading to premature failure.

In addition to lubrication and load management, monitoring operating conditions is crucial. Harsh environments can accelerate wear. If a spring shows sign of fatigue, replacing it sooner rather than later is advisable. Delaying replacement can lead to more extensive damage. Maintaining small touch springs requires diligence, but it's worth it for prolonged efficiency.